Case

ceramic various method of crushing and grinding

2020-12-17T02:12:04+00:00

ceramic various method of crushing and grinding

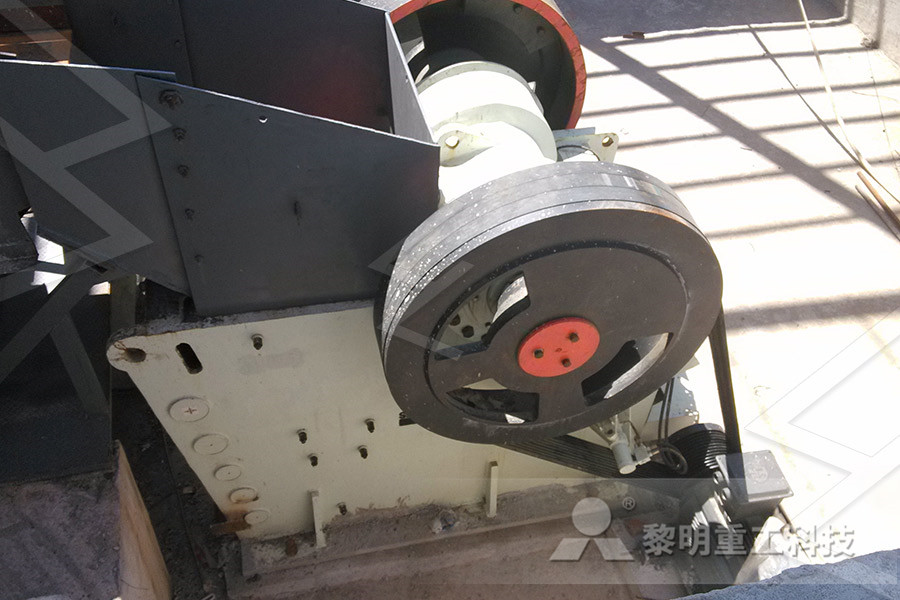

Ball Mill is the key equipment of crushing material, which is mainly used for single stage fine grinding, grinding, grinding circuit of grade two Widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry It is divided into dry method and wet grinding method Physical processes include impact, shear between two surfaces, and crushing by a normal force between two hard surfaces There are two broad types of ceramic raw materials that require milling These are classified as lumpy and powdered ceramics Lumps result from mining, fusion, and sinteringCERAMIC MATERIALS I Mu 1 A method for effecting a physicochemical reaction in, and further processing, a crystalline or amorphous material A, the method comprising: (a) crushing or grinding said material A thereby forming new fractured surfaces and, (b) subjecting the crushed or ground material to a following process step,Method of crushing and grinding Partek Concrete Ltd

Crushing And Grinding Samples caesarmachinery

Ore beneficiation equipment, sand making equipment, crushing equipment and powder grinding equipment, which are widely used in various industries such as metallurgy, mine, chemistry, building material, coal, refractory and ceramicsRoom temperature cold spray technique uses the nanosized/submicron ceramic particles as feedstock, and deposits ceramic coatings onto substrates through gas flows at room temperature Coating formations are based on the high velocity impact and impactinduced fragments of ceramic particlesCeramic Coating an overview ScienceDirect TopicsIn a process for producing an aluminosilicate ceramic proppant for use in fracturing of wells comprising performing crushing operations on bauxite clay to obtain particles of a desired size, agglomerating the particles to form pellets, and subjecting the pellets to a combined sintering and calcining process to thereby produce an aluminosilicate ceramic proppant, the improvement wherein the particles to be Aluminosilicate ceramic proppant for gas and oil well

Crushing Vs Grinding Minerallurgy

Crushing is usually a dry process, while milling is performed with water The advantage of wet milling is the lower energy input compared to dry milling Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the The Bureaupatented technique involves the intense agitation of a slurry composed of the material to be ground, a granular grinding medium, and a suspending fluid Investigations were made to determine the efficiency of the method in grinding Attrition Grinding Mill Design 911 Metallurgistceramics are based on simpler compounds such as oxides, nitrides, and carbides 2 List the basic steps in the traditional ceramics processing sequence The sequence is (1) preparation of raw materials, (2) shaping, (3) drying, and (4) firing Nice work!Chapter 17 Processing of Ceramics and Cermets

WELLWARESPreliminary Processing Of Raw wws

Ball mills are widely used in the processing of ceramic raw materials, wet grinding of various ores and other grindable materials Relying on the geographical advantage of the north, the factory has 11 ball mills with a capacity of 10 tons, which can hold 10 tons of mud, and 4 sets of ball mills with a 15 tons capacity and 15 tons of glazeLecture 33: Ceramic powder preparation The processing of raw The raw materials for powder preparation are generally natural minerals such method involves crushing, milling in a ball mill or grinding ceramic raw materials into small particlescrushing machine for ceramic raw materials The grinding forces that are obtained during the surface grinding of ceramic coatings are primarily governed by the the maximum uncut chip thickness h m and critical depth of cut d c The force profile obtained from the oscilloscope during grinding of the TiO 2 coating is shown in Fig 2 The calculated values of tangential and normal forces Grinding of hard and brittle ceramic coatings: Force

Recovery of abrasive grains from grinding wheel

The abrasive particles are typically ceramic, such as aluminum oxide, silicon carbide, cubic boron nitride, or diamond As with any product, waste is generated during the manufacturing process when faulty grinding wheels are discarded However, waste also occurs during operation because of the way grinding wheels are mounted on the grinding processing consists of crushing and grinding raw materials, followed if necessary by size classification and raw materials calcining and drying The processed raw material then may be drymixed with other minerals and chemical compounds, packaged, and shipped as product All of these processes are not required for some refractory products115 Refractory Manufacturing Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock ( geometallurgy ) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing Crushing in Mineral Processing 911 Metallurgist

bone prepared by grinding method

A new sawing‐grinding method is described for the histological evaluation of jaw bones with teeth or bones containing implants (ceramic or metallic) The undecalcified bone is embedded in acrylic resin and sawed at 100 to 150 μm The ceramic ball mill is mainly used for mixing and grinding of materials, the fineness of the product is uniform, and the power is saved It can be dry or wet The machine can adopt different liner types according to production needs to meet different needs The fineness of the grinding operation is controlled by the grinding Application and Working Principle of Ceramic Ball Mill Crushing And Grinding Samples Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc sample cutting and grinding machine : 48/5 1,663 Aug 06, 2012 concrete core grinding machine diamond Way Crushing And Grinding Samples caesarmachinery

Chapter 17 Processing of Ceramics and Cermets

ceramics are based on simpler compounds such as oxides, nitrides, and carbides 2 List the basic steps in the traditional ceramics processing sequence The sequence is (1) preparation of raw materials, (2) shaping, (3) drying, and (4) firing Nice work!Lecture 33: Ceramic powder preparation The processing of raw The raw materials for powder preparation are generally natural minerals such method involves crushing, milling in a ball mill or grinding ceramic raw materials into small particlescrushing machine for ceramic raw materials Ball mills are widely used in the processing of ceramic raw materials, wet grinding of various ores and other grindable materials Relying on the geographical advantage of the north, the factory has 11 ball mills with a capacity of 10 tons, which can hold 10 tons of mud, and 4 sets of ball mills with a 15 tons capacity and 15 tons of glazeWELLWARESPreliminary Processing Of Raw wws

ANALYSIS OF DRYING PROCESS IN CERAMIC TILES

Fig 1: Manufacturing process of ceramic tiles (2) Fine Grinding Milling The basic beneficiation processes include crushing, grinding, and sizing or classification Primary crushing is used to reduce the size of coarse materials, such as clays, down to approximately 1 The ceramic abrasive with solgel method are more pure than white corundum, much less impurities, and have higher hardness than white corundum Its uniform and fine microcrystalline structure, high toughness and micro crushing properties make it widely used in grinding tool steel, various Characteristics of Ceramic Abrasive with SolGel 15 Important tests for ceramic production quality assessment 2 SIZE REDUCTION 21 Various types of machines used in size reduction 22 Discuss various methods of crushing grinding 23 Various factors influencing grinding efficiency special emphasis on ball mill 24 Particle size analysis and various sieves and equipment used for itSTATE COUNCIL FOR TECHNICAL EDUCATION AND

ceramic grinding kaolin machine made in japan

mechanical activation of clay a novel route to DiVA tests have shown that the alkali activation of the processed clays produced solidified matrixes FWHM for kaolinite peaks 001 during dry and wet grinding with different B/P ratio In industry, clay is largely used for the production of various ceramic determined in a mechanical testing machine, type Instron model 1342 ceramic process and a chemicalbased method called sol gel process The traditional process involves consolidation of the powers in the desired shapes in a die and press method to obtain the green shape and thereafter in an isostatic press to have uniform density of the green shape In the sol gel method, two approaches can be usedSurface Finish Studies of ADENSE Alumina Ceramic Grinding In the context of comminution, grinding refers to the operation of reducing the small pieces after crushing to a fine powder Accomplished by abrasion, impact, and compaction by hard media such such as balls, pebbles or rods Examples of grinding include: – Ball mill – Roller mill – Impact grinding Ceramics SlideShare

Application of Alumina Grinding ALumina ceramic

The high hardness and high whiteness can greatly improve the crushing efficiency and reduce the pollution of materials Alumina grinding balls have been widely used in kaolin grinding Many customers are also consulting to measure its cost performance and various feasibility in this industryA new sawing‐grinding method is described for the histological evaluation of jaw bones with teeth or bones containing implants (ceramic or metallic) The undecalcified bone is embedded in acrylic resin and sawed at 100 to 150 μmbone prepared by grinding method