Case

bonds rod mill for work index

2020-07-14T20:07:07+00:00

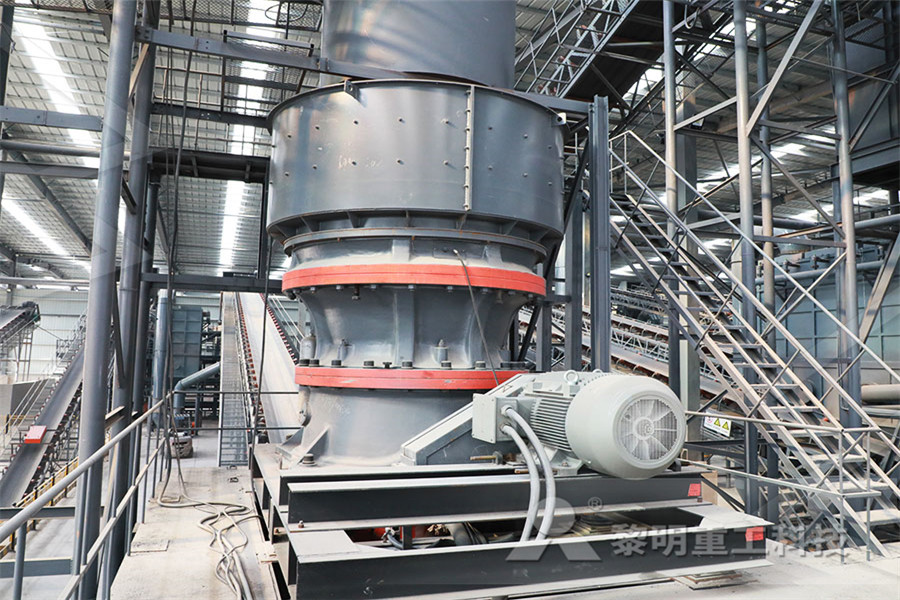

Bond Rod Mill Work Index Equipment Apparatus

Commentary on the apparatus of the Bond rod mill Work Index by Alex Doll December, 2015 alexdoll@sagmilling The Bond “Third Theory” of comminution was originally divided into three size classes reflecting the varieties of comminution To calculate Bond rodmill work indices, the four samples were screened and the particle size distributions plotted in Fig 2The plot was used to find F 80 of the samples for calculations Fig 3, Fig 4 show the grinding kinetics of Pb, Cu, Fe, and Mn ores in the Bond rodmill in different testsieves The slopes of all lines in the figures are equal to the k value of Eq determination of Bond rodmill work index by Bond Work Index an overview ScienceDirect Topics The rod mill work index laboratory test is conducted by grinding an ore sample prepared to 80% passing 127 mm (½ inch, the original test being developed in imperial units) to a product size of approximately 1 mm (in the original and still the standard, 14 mesh; see Chapter 4 for definition of mesh), thus determining the rod mill work index bonds rod mill for work index MC Machinery

Bond 39 S Rod Mill For Work Index

Bonds Rod Mill For Work Index Commentary on the apparatus of the Bond rod mill work index Apr 27 rod milling is fitted to a tumbling test referred to as the Bond rod mill work index WiRM or RWi The apparatus used to determine this work index was described in 1943 by Bond amp Maxton and a slightly different apparatus was described by Bergstrom in 1985For comparing the standard Bond rodmill work index and the new modeled Bond work index Rodmill method, work index (Wi) and produced fine particles in a cycle (Gi) for the four samples determined Grinding kinetics The performed paired Student’s ttest (PDF) determination of Bond rodmill work The rod mill work index laboratory test is conducted by grinding an ore sample prepared to 80% passing 127 mm (½ inch, the original test being developed in imperial units) to a product size of approximately 1 mm (in the original and still the standard, 14 mesh; see Chapter 4 for definition of mesh), thus determining the rod mill work index (Wi R or RWi) The ball mill work index laboratory test is Bond Work Index an overview ScienceDirect Topics

Bond Work Index Procedure and Method 911

The Work Index (BWi) is calculated according to Fred Bond’s Equation Bond Work Index for Testing Procedure Cleaning and Storing of Ball Mill Charge after the Bond Work Index Procedure is done: Add about 500 g of silica sand into the mill containing Bond Ball Mill Work Index, BWi, kWh/t 134 Bond Rod Mill Work Index, RWi, kWh/t 181 Table 1 Example of AG/SAG Ball Mill Circuit Wio Calculations [1] [2] ABstrAct Optimum use of power in grinding, both in terms of grinding efficiency and use of installed capital, can haveBond S Work Index Ball Mill mandzijowkapl The Bond's standard ball mill is used to determine the work index value of different samples The Bond work index is defined as the kilowatthours per short ton required to break from infinite size to a product size of 80% passing 100 µm If the breakage characteristics of a material remain constant over all size ranges, the calculated work index would be expected to remain constant since it indicates the CORRELATION BETWEEN BOND WORK INDEX AND

Testwork: Bond rod mill work index

Bond rod mill work index results from Australian laboratories with smooth liners should not be used in the models The test is a 'lockedcycle' test where ground product is removed from test cycles and replaced by fresh feed The test must achieve a steadystate before completionA “Bond” rod mill work index is to be determined in an apparatus with a wave liner The author is aware of four laboratories that offer a rod mill work index test where the lining of the mill is either smooth, or smooth with a small number of primitive lifters that do not constitute a wave liner (one ofCommentary on the apparatus of the Bond rod mill work The grinding jar for the Bond Index Rod Mill is 12″ x 24″ in size and has a waveshaped design At least 15 to 20 kg sample material is required to simulate a closed grinding circuit in a ball or rod mill The Rod Mill Work Index (RWI) is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work Bond Index Ball Mill / Rod Mill BT 100 XL RETSCH

Sag Mill And Ratio Of Bond Ball And Rod Work Index

CORRELATION BETWEEN BOND WORK INDEX AND 3 STANDARD BOND TESTS The Bonds standard ball mill is used to determine the work index value of differ ent samples The Bond work index is defined as the kilowatthours per short ton required to break from infinite size to a product size of 80 passing 100 mBond Rod Mill Index Test JKTech A Bond RMWI test is a standard test for determining the Rod Mill Work Index of a sample of ore The BRMWI is a measure of the resistance of the material toBond Rod Mill Work Index In this paper, systematic errors encountered in a rod mill Bond Work Index determination related to the weight and size distribution of the sample are first estimated experimentally The first type is shown to be relatively small, whereas the second can be as high as 3 kWh/t when the feed size F 80 is finer than 30 mm A phenomenological basis Error analysis for bond work index determinations

Error analysis for bond work index determinations

Minerals Engineering, Vol 6, No 5, pp 509521, 1993 $600+000 Printed in Great Britain Pergamon Press Ltd ERROR ANALYSIS FOR BOND WORK INDEX DETERMINATIONS PART 2: A PHENOMENOLOGICAL BASIS FOR THE ANALYSIS OF SYSTEMATIC ERRORS FOR THE ROD MILL TEST AR LAPLANTE U PRASAD RE MclVORI and JA FINCH Dept of Mining correlation between the abrasion value(X2) and work index (Wi) is found to be Wi = 18 Ln (X2) + 115 with correlation coefficient of 080 KEYWORDS: Bond work index ± Mechanical properties of rocks ± Grinding energy Crushing resistance 1 INTRODUCTION Comminution in a mineral processing plant, or mill, involves a sequence of crushi ngCORRELATION BETWEEN BOND WORK INDEX AND Assume the test Wi of the rod mill (95) applies from the actual rod mill feed size of 19,300 µm (although some of this work might ideally be done by crushers to achieve a rod mill F80 of 16,000 µm) to a rod mill (circuit) product size of 1,000 µm 10 10 W1( –––––––-–––––––––) ( Bond EfficiencyGMGICEv1r04 Determining

Relationships between comminution J energy and

determination of the work index for ball and rod mills in 1952 and modified it in 1961 The standard Bond ball mill grindability test is a closed circuit dry grinding test with a 250% circulating load The standard procedural outline of the test is stated in (Bond) 1961 The work index for a ball mill, Wi, is then calculated from the following Bond rod mill work index results from Australian laboratories with smooth liners should not be used in the models The test is a 'lockedcycle' test where ground product is removed from test cycles and replaced by fresh feed The test must achieve a steadystate before completionTestwork: Bond rod mill work index The Bond Work Index for Rod Mill is a special equipment for testing Bond rod mill work index Simple lab test can choose rod mill by power method or judge the effects of material properties change to the rod milling process or the operation condition of rod mill by using this equipment From 1980s, the company developed the equipment and Laboratory Equipment,China Bond Work Index for

Bond Rod Mill Work Index

Bond Rod Mill Index Test JKTech A Bond RMWI test is a standard test for determining the Rod Mill Work Index of a sample of ore The BRMWI is a measure of the resistance of the material to Bond Work Index for Rod Mill Product Image Introduction The Bond Work Index for Ball Mill is a special equipment for testing Bond ball mill work index Simple lab test can choose ball mill by power method or judge the effects of material properties change to the ball milling process or the operation condition of crusher by using this China Bond Work Index for Rod Mill Manufacturers A “Bond” rod mill work index is to be determined in an apparatus with a wave liner The author is aware of four laboratories that offer a rod mill work index test where the lining of the mill is either smooth, or smooth with a small number of primitive lifters that do not constitute a wave liner (one ofCommentary on the apparatus of the Bond rod mill work

(PDF) determination of Bond rodmill work

For comparing the standard Bond rodmill work index and the new modeled Bond work index Rodmill method, work index (Wi) and produced fine particles in a cycle (Gi) for the four samples determined Grinding kinetics The performed paired Student’s ttest Minerals Engineering, Vol 6, No 5, pp 509521, 1993 $600+000 Printed in Great Britain Pergamon Press Ltd ERROR ANALYSIS FOR BOND WORK INDEX DETERMINATIONS PART 2: A PHENOMENOLOGICAL BASIS FOR THE ANALYSIS OF SYSTEMATIC ERRORS FOR THE ROD MILL TEST AR LAPLANTE U PRASAD RE MclVORI and JA FINCH Dept of Mining Error analysis for bond work index determinations bond work index determination with a sepor batch ball mill Bond ball mill work index determination grinding dear all have a good day i am trying to determine ball mill work index for a very soft if i follow bonds procedure to do experiment not able to determine the following is the data of ore sample f mic mesh of grind mic mic in feed in this case if the sample is gri get pricebond ball grinding mill work index determination

Bonds Work Index Ball Mill Inner Liners Design

Tubular Rod Mills Sciencedirect Grindability index for the ball mill 12Product size from the ball mill 150 mDetermine the size of the ball mill operated in closed circuitSolution step 1The discharge from the rod mill is the feed to the ball millTherefore, in this case, the work, w, will be w 120 10 1 150 1 1000 kwh tStep 2 corrections to