Case

Ball Mill Dry Process Diagram

2022-12-07T22:12:55+00:00

ball mill dry process diagram chevalsportfr

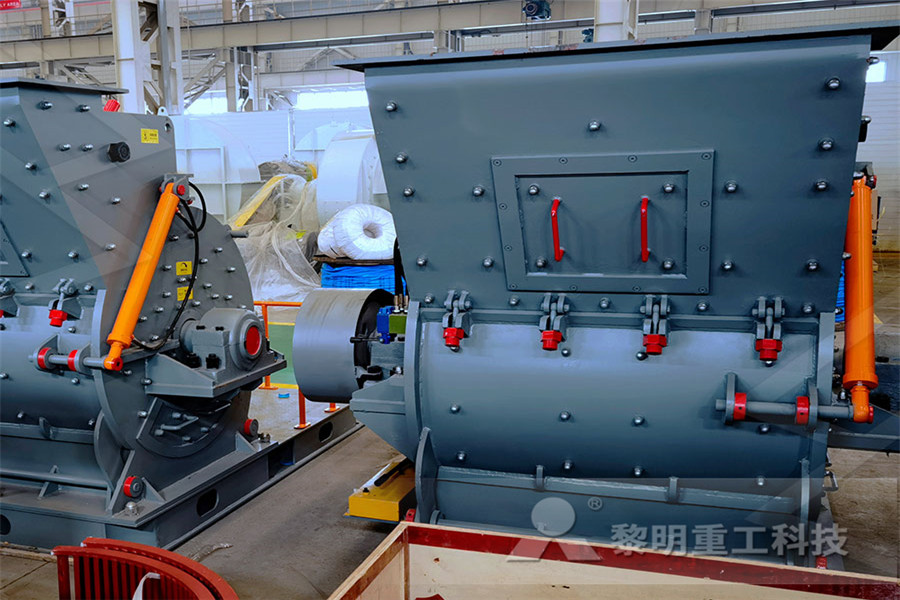

Line diagram of ball mill with separator Ball mills could operate dry or even process a water suspension (almost always for ores) Dry, it is fed through a chute or a screw through the unit’s opening In a wet path, a system of scoops that turn with the mill is used and it plunges into a stationary tankget priceBall mills could operate dry or even process a water suspension (almost always for ores) Dry, it is fed through a chute or a screw through the unit’s opening In a wet path, a system of scoops that turn with the mill is used and it plunges into a stationary tankBall Mills an overview ScienceDirect TopicsBall ball mill motor power wiring diagramPlanta trituradora 100 t h process crusher planta trituradora 100 t h 147 views the is the professional mining equipments manufacturer in the world contacto proveedor planta trituradora h t 100 planta trituradora h t 100 solicitar una cotizacin las cocinas de tailandia get pricegtgt plantas de agregados ball mill dry process diagramhtml kwiatkowskiskorypl

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

The process is continuously repeated as the particles move by mass and volume action through the mill Dry and wet grinding common Ball mill photographed by Ron Frisard and shared on Flickr, CC Diagram of ball mill and interior cut away [image: (13572)]Ball mill exterior, interior, and grinding media [image: (135611)] Pebble Mill Pebble mill diagram [image: (135613)] Wet or dry; Always grate discharge; Secondary grinding; Grinding media : A size fraction screened out from feed; Flint pebbles; Porcelain balls; Al203 balls; Larger than Ball mills at AMIT 135: Lesson 6 Grinding Circuit – Mining Mill wet ball mill bentonite wet ball mill zswtorunpl Wet Ball Mill High Bentonite eifschaltanlagenbaude Grinding Mill For Bentonite Panola Mining Machine bentonite powder grinding plant ball mill for bentonite processing ball mill is the world favorite machine in the process of grinding ore minerals or other materials ball mill can be processed in dry or wet grinding applications the wet ball ball mill diagram for bentonite in canada

Ball Mill SlideShare

There are two ways of grinding: the dry process and the wet process It can be divided into tubular type and flowing type according to different forms of discharging material Fig1 Manhole of batch ball mill • Batch ball mill : The balls as will as the feed The ball milling process prepared by rod mill, sag mill (autogenous / semi autogenous grinding mill), jaw crusher, cone crusher, and other single or multistage crushing and screening 【 Ball mill manufacturer 】 With more than 35 years of experience in grinding balls mill technology, JXSC design and produce heavyduty scientific ball mill Ball Mills Industry Grinder for Mineral Processing Corn dry milling operations are specially designed to manufacture fuelgrade ethanol in a “oneshot” process directly from the whole corn kernels For this purpose, shelled corn arrives at the drymill processing facility and through processing via a hammer mill the entire corn kernel is ground into a mediumcoarse to fine flour, which is referred to in the industry as “meal” and processed without Dry Milling an overview ScienceDirect Topics

ball mill diagram for bentonite in canada

wet ball mill bentonite wet ball mill zswtorunpl Wet Ball Mill High Bentonite eifschaltanlagenbaude Grinding Mill For Bentonite Panola Mining Machine bentonite powder grinding plant ball mill for bentonite processing ball mill is the world favorite machine in the process of grinding ore minerals or other materials ball mill can be processed in dry or wet grinding applications the wet ball A diagram of the process, which In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, thereby producing a pumpable slurry, or slip, of approximately 65 percent solids Dry process pyroprocessing systems have been improved in thermal efficiency and productive116 Portland Cement ManufacturingThe mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill

AN OVERVIEW OF LIME SLAKING AGT Group

C BALL MILL SLAKERS Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking Two types of ball mills are used for slaking, horizontal and vertical Ball mill slakers are generally used where: the capacity required is too large for other types of slakers The ball to charge ratio may be 5:1, 10:1, 15:1 This method is more efficient in achieving fine particle size Rod mills: Horizontal rods are used instead of balls to grind Granularity of the discharge material is 4010 mm The mill speed varies from 12 to 30 rpm Planetary mill: High energy mill widely used for producing metal, alloy, and Powder metallurgy – basics applications Ethanol Production Processes : ›DRY MILLING ›WET MILLING ›CELLULOSIC BIOMASS DRY MILLING In dry milling, the entire corn kernel or other starchy grain is first ground into flour, which is referred to in the industry as "meal" and Ethanol Production Process : Dry Milling

Attritor, How attritor Works, Attritor working, Dry

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball mill2 天前 The corn dry milling process is a less versatile, less capital intensive process that focuses primarily on the production of grain ethanol In this process the corn kernels are hammer milled into a mediumtofine grind meal for introduction to the ethanol production process The products of a traditional dry Corn Milling: Wet vs Dry Milling AMG Engineering groups [1] [2] [18] [12][25] analysed the mixing of lithium battery materials using ball mill mixers, and found that the solution viscosity would drop gradually and approached a stable, limiting value after a long periodof mixing A ball mill mixer appears to be a suitable device for mixing electrode slurries, although its effectiveness isAn Effective Mixing for Lithium Ion Battery Slurries

Spray Dryer: Operating principles, Process layout, Uses

Spray dryer is used in drying pharmaceuticals like penicillin, blood products, enzymes, vaccines, etc 2 It is used in the production of excipients and coprocessed excipients with increased flowability, compatibility, and tablet disintegration 3 To Diagram of ball mill and interior cut away image 13572 ball mill design parameters size rated as diameter x length feed system one hopper feed diameter 40 100 cm at 30 to 60 furthermore the ball mill of a large capacity has been available to a very extensive range of applications in both dry and wet Aug 10 2020 gather the necessary Simple Diagram Of Ball Mill Ball Mill A ball mill is one kind of grinding machine, and it is a process Kano et al8) found that it was the impact energy of the balls that has a large effect on the grinding Rocking mills (ball mills where the pot is rocked Fig 2 Schematic diagram of the rocking ball millDesign Method of Ball Mill by Sumitomo Chemical Co,

1125 Clay Processing US EPA

The shredded material then is either dried or ground in a hammer mill Material exiting the hammer mill is mixed with water and bulk loaded as a slurry for shipping Figure 11253 depicts the process flow for ball clay processing Indirect rotary or vibrating grate dryers are used to dry ball clay Combustion gases from the A diagram of the process, which In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, thereby producing a pumpable slurry, or slip, of approximately 65 percent solids Dry process pyroprocessing systems have been improved in thermal efficiency and productive116 Portland Cement ManufacturingThe vector stencils library "Industrial equipment" contains 81 symbols of pumps, compressors, fans, turbines, and power generators Use these shapes to design pumping systems, air and fluid compression systems, and industrial process diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Process Flow Diagram Symbols ConceptDraw

Ball Mill Working Principle And Main Parts

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material The operating principle of the ball mill GSM dry process ball mill GSM stirred type grinding machine has the unique patented design concept It contains a brand new internal structure of the grinding cylinder, where allows for a higher degree of rotation speed to realize finer grinding, which adopts continuous operation of GSM dry process ball mill

China 2400*8000 Ball Mill Dry Grinding Process for

2400*8000 Ball Mill Dry Grinding Process for Limestone Powder picture from Zhengzhou Hengxing Heavy Equipment Co, Ltd view photo of Ball Mill Dry Process for Limestone, Ball Mill, Dry Ball MillContact China Suppliers for More Products and Price The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process the materials are ground and mixed dry The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure 33 The limestone is disintegrated in crushers The crushed limestone is fed to a tube mill Explain dry and wet process of cement manufacturing