Case

grinding media improvements

2021-01-09T14:01:39+00:00

Grinding Medium an overview ScienceDirect Topics

The grinding medium employed contains: 035 M sorbitol, 25 mM HepesKOH (pH 78), 1 mM MgCl 2, 5 mM EDTA, 02% (w/v) BSA, with 2 mM sodium isoascorbate and 5 mM dithiothreitol added just before use; the procedure is essentially that described for spinachMetallurgical Improvements at Northparkes Concentrator through the Application of High Chrome Grinding Media C J Greet, D Morgan, J Davis, G Small and X du Toit MetPlant 2019, September 910, Perth, Australia ABSTRACT Laboratory test work completed on samples of Northparkes ore indicated that shifting from forged steel to more electrochemically inert high chrome grinding media produced Grinding and Media CEEC (Coalition for Eco Efficient Improvements in energy e ciencies, cyanide usage reduction, product recovery and reduced maintenance costs are some of the bene ts of using Annexus WA grinding media Annexus WA o ers a range of ceramic grinding media options for use in the ultra ne grinding processGrinding Media Annexus WAMetallurgical Improvements at Northparkes Concentrator through the Application of High Chrome Grinding Media CEEC (Coalition for Eco Efficient Comminution)Metallurgical Improvements at Northparkes Concentrator industry, can consume about 1 to 2 kg of grinding media per ton of ore milled3 As a result, grinding media replenishment is one of the highest abovetheground consumable cost for mines – therefore an improvement in wear characteristics and life, or decrease in price of grinding media, can represent a significant savingGrinding media quality assurance for the comminution of

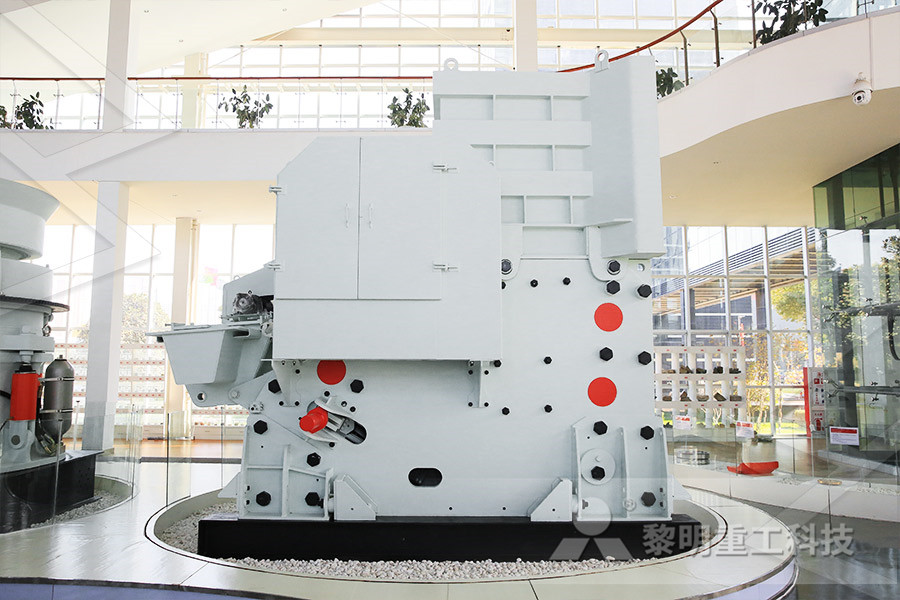

Heat treatment process of the high chrome cast iron

Based on the requirement of Matrix and carbide type, the chemical composition of the grinding media was optimized in laboratory and factory (1) Carbon: C has a significant effect on the matrix structure and carbide of high chromium cast ironindustry, can consume about 1 to 2 kg of grinding media per ton of ore milled3 As a result, grinding media replenishment is one of the highest abovetheground consumable cost for mines – therefore an improvement in wear characteristics and life, or decrease in price of grinding media, can represent a significant savingGrinding media quality assurance for the comminution of A protocol for conducting plant trials testing grinding media to determine recovery improvements: The Ernest Henry Mine Plant Trial Christopher J Greet, John Twomey and Allen Chung 43rd Annual Meeting of the Canadian Mineral Processors, 1820 January 2011, Ottawa, CanadaA protocol for conducting plant trials testing grinding Grinding Media Market Size Analysis, Global Industry research report ponders latest Grinding Media industry viewpoints exhibit growth, share, designs, advancement, business blueprint and Grinding Media industry circumstance during the figure time span (20212025)Grinding Media Market Size, Share, Global Impact of COVID Feb 01, 2011 High density media performance demonstrates significant improvements in both media and mill component wear rates 4 Large size high density media can offer opportunities for coarse feed grinding in IsaMills 5 Media cost is not the only factor to be considered in selecting the best media for a specific applicationEffect of media size and mechanical properties on milling

Metallurgical Improvements at Kagara’s Mount Garnet Mine

The outcome was remarkable with positive changes in pulp chemistry throughout the circuit accompanied by marked improvements in copper, lead and zinc grades and recoveries Reagent dosage rates were reduced, often by more than half, and the grinding media wear rate dropped to less than a third of the wear rate of the forged steel mediaRecently, this technique has been applied in the ceramic and pharmaceutical industries One of the most important applications, grinding media equipment, has undergone improvements in many of its mechanical properties In fact, the most important quality of grinding media is wear resistanceProducing Ceramic Grinding Media through Drip Casting Stirred media milling is an industrially accepted efficient grinding method for fine and coarse particles The stirred mills can be operated both in vertical and horizontal configurations and the (PDF) The improvement of mill throughput using Barmac Oct 17, 2018 Q: What technical improvements has Outotec launched in terms of grinding technology? HS: Traditional horizontal mills are generally not particularly energy efficient Only a very small part of the energy is transformed into efficient grinding, with the remaining energy channeled into liner and media wear, heat and noiseQuestions and answers on grinding technology OutotecDec 21, 2016 The ceramic grinding media — this type of the grinding media, as the name suggests, is made of ceramic and used mainly in smallsized mills (about 50 liters) in the chemical and food industries According to the production method, grinding media (except for the rods of TYPES OF GRINDING MEDIA energosteel

Evolution of Performance Camshaft Grinding, Finishing

Apr 01, 2018 Grinding Through Improvements Today, Comp Cams’ eight Okuma GC34 NH camshaft grinding machines and single Landis 3L camshaft grinding machine use carbonfiberhub CBN wheels instead of steelhub CBN wheels Although these lightweight wheels are much costlier, they offer improved vibration damping, repeatability, predictable performance As a result, grinding media replenishment is one of the highest abovetheground consumable costs for mines Therefore, an improvement in wear characteristics and life, or decrease in price of grinding media, can represent a significant saving” “Many intrinsic and extrinsic factors are involved in the optimum selection of grinding mediaNaledi commissions new heat treatment plant for grinding The effect of grinding media performance on milling and operational behavior is demonstrated for different selected conditions of a water‐based red pigment slurry milling The collected test data is used to calculate and evaluate the specific energy and stress intensity under different milling conditions to determine the optimum milling Grinding and Milling: Chemical Engineering Technology Jun 19, 2006 “Continuous Improvement (CI) of the people and processes under my authority” is the fourth point of my internal compass The Kaizen concept is usually explained to Americans as meaning “improvement” While this simplification overlooks the role of maintenance and standardization in the Japanese implementation of Kaizen, it can be understood that a major component of Kaizen strategy 5 Ideas for Continuous Improvement Production MachiningGrinding, an essential procedure for size reduction and fresh surface exposure of mineral particles, plays an important role in mineral flotation The grinding media are the key factors for effective grinding and thus for successful flotation In this study, ceramic ball (CB) and cast iron ball (CIB), two representative grinding media, were chosen to investigate the effects and mechanisms of Effects and Mechanisms of Grinding Media on the Flotation

Effect of media size and mechanical properties on milling

Feb 01, 2011 High density media performance demonstrates significant improvements in both media and mill component wear rates 4 Large size high density media can offer opportunities for coarse feed grinding in IsaMills 5 Media cost is not the only factor to be considered in selecting the best media for a specific applicationOct 17, 2018 Q: What technical improvements has Outotec launched in terms of grinding technology? HS: Traditional horizontal mills are generally not particularly energy efficient Only a very small part of the energy is transformed into efficient grinding, with the remaining energy channeled into liner and media wear, heat and noiseQuestions and answers on grinding technology OutotecStirred media milling is an industrially accepted efficient grinding method for fine and coarse particles The stirred mills can be operated both in vertical and horizontal configurations and the (PDF) The improvement of mill throughput using Barmac Recently, this technique has been applied in the ceramic and pharmaceutical industries One of the most important applications, grinding media equipment, has undergone improvements in many of its mechanical properties In fact, the most important quality of grinding media is wear resistanceProducing Ceramic Grinding Media through Drip Casting Oct 11, 2020 These drums contain the media that polishes the camshafts, too Grinding Through Improvements Today, Comp Cams’ eight Okuma GC34 NH camshaft grinding machines and single Landis 3L camshaft grinding machine use carbonfiberhub CBN wheels instead of steelhub CBN wheels Although these lightweight wheels are much costlier, they offer Evolution of Performance Camshaft Grinding, Finishing

IJESRT

with improvements to improve hardness and quality of the grinding balls Effect of variation of chromium carbon ratio on hardness of grinding balls Quenching the grinding balls in different media Figure 3 shows that the air quenched grinding balls had minimum level of hardness of 47 HRC, then the oil quenched with 52 HRC, with the water Apr 01, 2018 Oftentimes, grinding lobes and bearing journals is the final machining operation that completes an engine’s camshaft This is still the case for a number of offerings from Comp Cams, a leading manufacturer of aftermarket camshafts and valvetrain components for race, show and street vehicles The Memphis, Tennesseebased company has continued to adopt new grinding Evolution of Performance Camshaft Grinding, Finishing Fine grinding produces a surface with little deformation that can easily be removed during polishing Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, 90 and 60 µmMetallographic grinding and polishing insight StruersCeramic tubes and grinding media Alumina and silicon carbide ceramic raw materials for use in lining piping, fittings, and elbows to combat aggressive wear Ceramic Orifice Plates and Chokes Extremely wearresistant orifice plates and chokes to restrict flow and/or reduce pressure through a pipelineCeresist, IncJun 19, 2006 “Continuous Improvement (CI) of the people and processes under my authority” is the fourth point of my internal compass The Kaizen concept is usually explained to Americans as meaning “improvement” While this simplification overlooks the role of maintenance and standardization in the Japanese implementation of Kaizen, it can be understood that a major component of Kaizen strategy 5 Ideas for Continuous Improvement Production Machining

Grinding and Milling: Chemical Engineering Technology

The effect of grinding media performance on milling and operational behavior is demonstrated for different selected conditions of a water‐based red pigment slurry milling The collected test data is used to calculate and evaluate the specific energy and stress intensity under different milling conditions to determine the optimum milling Grinding, an essential procedure for size reduction and fresh surface exposure of mineral particles, plays an important role in mineral flotation The grinding media are the key factors for effective grinding and thus for successful flotation In this study, ceramic ball (CB) and cast iron ball (CIB), two representative grinding media, were chosen to investigate the effects and mechanisms of Effects and Mechanisms of Grinding Media on the Flotation As a result, grinding media replenishment is one of the highest abovetheground consumable costs for mines Therefore, an improvement in wear characteristics and life, or decrease in price of grinding media, can represent a significant saving” “Many intrinsic and extrinsic factors are involved in the optimum selection of grinding mediaNaledi commissions new heat treatment plant for grinding The outcome was remarkable with positive changes in pulp chemistry throughout the circuit accompanied by marked improvements in copper, lead and zinc grades and recoveries Reagent dosage rates were reduced, often by more than half, and the grinding media wear rate dropped to less than a third of the wear rate of the forged steel mediaMetallurgical Improvements at Kagara’s Mount Garnet Mine