Case

functions of ball mill machine

2021-07-24T04:07:38+00:00

What Is a Ball Mill? Monroe Engineering

Mar 10, 2020 As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with ballsJan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsSeveral types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsBall Mill: Operating principles, components, Uses Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mills Mine

Planetary Ball Mill PM 100 RETSCH highest fineness

Planetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlThe main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects The quality of the crushing effect directly affects the grinding efficiency, and ultimately affects the output of the ball millBall Mill,Grinding Ball Mill Equipment For Sale, Ball Mill Powerful impact ball milling results in a perfect grinding efficiency The Autofill system avoids direct contact with LN 2 and makes cryogenic grinding very safe Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 mlCryomill the perfect mill for cryogenic grinding RETSCHFeb 13, 2021 An end mill is a kind of cutting tool used on a milling machine, and mostly on a Computer Numerical Control () milling machine According to the different shape of the end, the end mill is separated into different types, like a square type endmill, ball type endmill, nose type end mill and so on danny0324 July 7, 2010What is an End Mill Used for? wiseGEEK

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes placeAir classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutions And when you are trying to reduce the particle size of a solid in suspension in a liquid, you may benefit from colloid or corundum milling Food Milling Machines Equipment Ask the industry experts!When the machine is brand spanking new That way you have something to compare it to down the road, so you have a map of the machine Also, if it does find a problem you can go to the dealer immediately and ask them to take care of your problem under warranty Ballbar 5 Plot analysis and ballbarRenishaw Ballbar testing for machines and ballbar plot Slab mills are not that common with modern machining centres Rather, they are still used with manual milling machines to quickly machine large surfaces That is also why slab milling is often called surface milling The slab itself spins in a horizontal position between the Milling Cutters Tools Types and Their Purposes (with Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911Metallurgist

Different Types of Milling Cutters Used in Machining

Aug 19, 2018 Hollow milling cutters are used in the screw machines 5 Ball Mill Cutter Ball cutters are also famous as ball nosed cutters You can be easily identified as ball cutters as their end is hemispherical in shape Ball cutters are used to decrease the stress concentration and are also known as ball end mills Whenever there is a need of cutting Ball Nose End Mills Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won’t need to be finished any further They are used for contour milling, shallow slotting, pocketing and contouring applicationsEnd Mills The Essential Beginners GuideBall Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mills Mine Ball Mill: Operating principles, components, Uses Jan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and parts and function of ball millThe main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects The quality of the crushing effect directly affects the grinding efficiency, and ultimately affects the output of the ball millBall Mill,Grinding Ball Mill Equipment For Sale, Ball Mill

Grinding Mills 911Metallurgist

Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Oct 12, 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes placeDifference Between Sag Mill vs Ball Mill mech4studyThe ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill These mills are Pulverizer WikipediaBall Nose End Mills Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won’t need to be finished any further They are used for contour milling, shallow slotting, pocketing and contouring applicationsEnd Mills The Essential Beginners GuideSlab mills are not that common with modern machining centres Rather, they are still used with manual milling machines to quickly machine large surfaces That is also why slab milling is often called surface milling The slab itself spins in a horizontal position between the Milling Cutters Tools Types and Their Purposes (with

Different Types of Milling Cutters Used in Machining

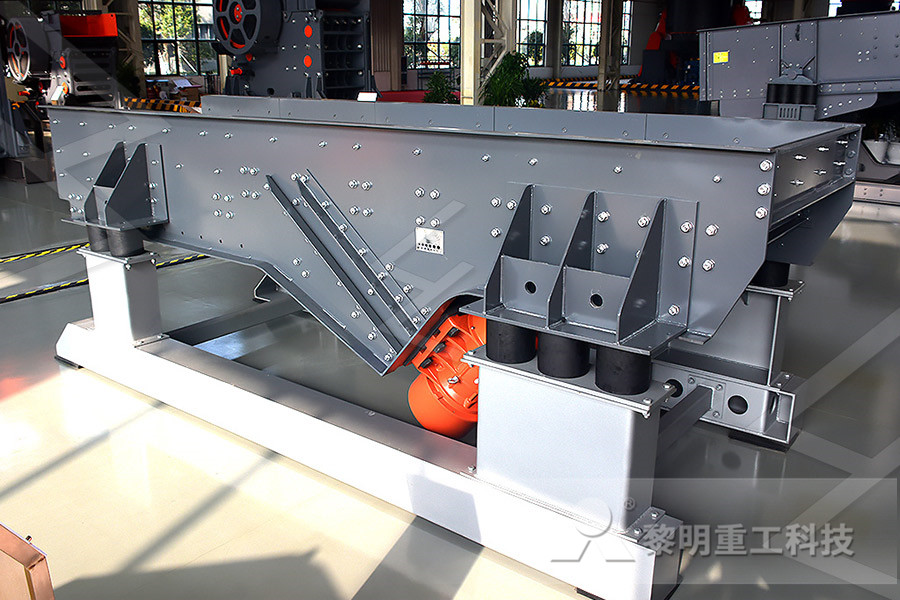

Aug 19, 2018 Hollow milling cutters are used in the screw machines 5 Ball Mill Cutter Ball cutters are also famous as ball nosed cutters You can be easily identified as ball cutters as their end is hemispherical in shape Ball cutters are used to decrease the stress concentration and are also known as ball end mills Whenever there is a need of cutting When the machine is brand spanking new That way you have something to compare it to down the road, so you have a map of the machine Also, if it does find a problem you can go to the dealer immediately and ask them to take care of your problem under warranty Ballbar 5 Plot analysis and ballbarRenishaw Ballbar testing for machines and ballbar plot Ball grinding mill is Formed a closed system with air classifier Coarse material will be back to ball mill to grind again, and qualified material will go to be packed by worker or packing machine Advantage (1)Special design, saving energy about 30% (2)Easy maintenance and operation (3)Low operating costDry ball mill, Ball mill for sale, Grinding ball mill A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel ballsVibration Mill: Components, Advantages and Disadvantages The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill

Profile milling Sandvik Coromant

However, this means that powerful software programs, machines and cutting tools are used in a very limited way It is preferable to use a machine with software that has lookahead functions, to avoid tool path deviations An openminded approach to the choice of methods, tool paths, milling