Case

mining tailings centrifugal magnetic separator for ball mill

2021-06-16T01:06:18+00:00

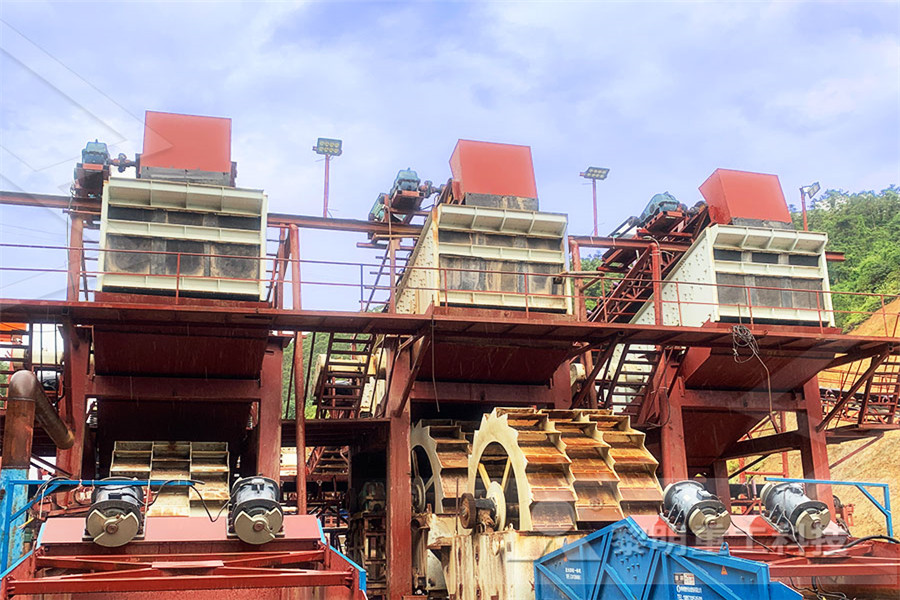

Magnetic Separator and Ball Mill YX

Magnetic separator is used to recycle powdered granules to remove iron powder and other screening equipment After the slurry flows into the tank through the feeding box, under the action of the water flow from the mine spray pipe, the ore particles enter the Any nonmagnetic material which has been released by the rod mill is separated and sent to the tailings thickener Magnetite iron ore particles are separated by the magnetite separator from the gangue (waste material) minerals in the cobber magnetic separators This material flows to the ball mill for further size reduction Material from the Tailings Mineral Industry Solution WesTech Engineering, Inc03 Under the condition that the grade of the dry tailings is equal to or even lower than that of conventional magnetic roller or conventional dry separator, for highgrade and lean magnetite with different features, by adjusting corresponding technical parameters and structure, about 10%30% tailings discharging and about 10%87% of concentration grade can be increased compared to Dry Magnetic Separator, Magnetic Separator Working The periodic high gradient magnetic separator works in three stages, feeding, washing and flushing The slurry (concentration is generally about 30%) enters the sorting zone slowly, the magnetic particles are adsorbed on the steel wool, and the remaining slurry is High Gradient Magnetic Separator HGMS JXSC MachineTailings can be divided into the following types: handpicking tailings, gravity separation tailings, magnetic separation tailings, flotation tailings, chemical beneficiation tailings, electrification tailings Why should we carry out the tailings retreatment process? Usually, the ore tailings are stored in the tailings Mine Tailings Retreatment Process JXSC Machine

Magnetic Separator and Ball Mill YX

Magnetic separator is used to recycle powdered granules to remove iron powder and other screening equipment After the slurry flows into the tank through the feeding box, under the action of the water flow from the mine Tin reduction process of magnetic tailings flotation 121020; 73 Views; icon 0; In the ball mill grinding process, the raw ore is ground to 0074mm, accounting for 60%, and the magnetic separator is used for magnetic rough separationThe magnetic field strength is 96kA/m The obtained coarse concentrate is reground to 0045mm, accounting for 787 %, the iron ore produced by magnetic The process of magnetic tailings flotation,iron ore Any nonmagnetic material which has been released by the rod mill is separated and sent to the tailings thickener Magnetite iron ore particles are separated by the magnetite separator from the gangue (waste material) minerals in the cobber magnetic separators This material flows to the ball mill Tailings Mineral Industry Solution WesTech Engineering, IncCentrifugal Concentrator Working principle The STL100(80)A centrifugal concentrator is a gravity separation equipment based on the density of minerals It produces different moving speeds and trajectories through the density and particle size of different materials to achieve the purpose of separationCentrifugal Concentrator Prominer (Shanghai) Mining There are many weak magnetic ores that are bulk and need to be crushed first, crushing, grinding then magnetic separation The general process flow is ore analysis, jaw crusher, screen, roller crusher, ball mill, magnetic separationHigh Gradient Magnetic Separator HGMS JXSC Machine

Mineral processing Wikipedia

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be useful in mining iron as it is attracted to a magnet In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine Tailings can be divided into the following types: handpicking tailings, gravity separation tailings, magnetic separation tailings, flotation tailings, chemical beneficiation tailings, electrification tailings Why should we carry out the tailings retreatment process? Usually, the ore tailings are stored in the tailings Mine Tailings Retreatment Process JXSC MachineThe main component of the leadzinc tailings are quartz and suicide sericite Except the methods of stockpiling in tailings pool, drytailing stacking and mine filling, Xinhai will also apply gravity separation, flotation separation, magnetic separation, gravity flotation separationMine Tailings, Tailings in Mining, Gold Tailings Related equipment: Jaw crusher, ball mill, magnetic separator, spiral separator, spiral chute, dryer the electric separator is the main electric titanium mining process equipment 3 Magnetic separation process The role of weak magnetic separation is to separate the titanomagnetite remaining in the magnetic separation tailings Titanium Mining Process Titanium Dioxide Mining Mining Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an oreTailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed The extraction of minerals from ore can be done two ways: placer miningTailings Wikipedia

China Gold Mining Machine Gold Separator Gold Centrifuge

The Gold Centrifugal Concentrator: Water Jacket Gold Separator; Knelson Concentrator The Gold Centrifugal Concentrator is a centrifuge device used primarily in gold mining The device is a gravity 6 Wolfram tailings: Use gravity, magnetic, flotation, etc process, and the gravity separation is the frequently used process The gravity separation for reselecting wolfram tailings is spiral chutecentrifugal separator(or wet strong magnetic separatorTailings ReProcessing YANTAI FULIN MINING MACHINERY Magnetic separator is used to recycle powdered granules to remove iron powder and other screening equipment After the slurry flows into the tank through the feeding box, under the action of the water flow from the mine spray pipe, the ore particles enter the Magnetic Separator and Ball Mill YXTin reduction process of magnetic tailings flotation 121020; 73 Views; icon 0; In the ball mill grinding process, the raw ore is ground to 0074mm, accounting for 60%, and the magnetic separator is used for magnetic rough separationThe magnetic field strength is 96kA/m The obtained coarse concentrate is reground to 0045mm, accounting for 787 %, the iron ore produced by magnetic The process of magnetic tailings flotation,iron ore Any nonmagnetic material which has been released by the rod mill is separated and sent to the tailings thickener Magnetite iron ore particles are separated by the magnetite separator from the gangue (waste material) minerals in the cobber magnetic separators This material flows to the ball mill for further size reduction Material from the Tailings Mineral Industry Solution WesTech Engineering, Inc

Dry Magnetic Separator, Magnetic Separator Working

03 Under the condition that the grade of the dry tailings is equal to or even lower than that of conventional magnetic roller or conventional dry separator, for highgrade and lean magnetite with different features, by adjusting corresponding technical parameters and structure, about 10%30% tailings discharging and about 10%87% of concentration grade can be increased compared to Strong centrifugal force produced by high speed spin strengthens the process of gravity separation and effectively recover the fine ore particles Nowadays, centrifugal c +863716330 3268 Whatsapp:+86Centrifugal Gold ConcentratorThe Nile Co, LtdJan 01, 2015 Figure 92 shows a permanent magnetic drum separator, which consists mainly of a permanent magnet system, a rotating drum, a separating chute, a feed tank, and a flushing pipe For magnetite separation, the magnetic field intensity on the surface of the drum is between 01 and 04 THowever, for other applications, the intensity may reach as high as 08 TDevelopments in the physical separation of iron ore Grinding and magnetic separation stage: The process of stagegrinding and stageseparation was adopted The mills of firststage, secondstage and thirdstage grinding were respectively grid ball mill, overflow ball mill, and overflow ball mill, three mills in total; the grinding fineness of them was respectively 200 meshes (40%), 200 meshes (87%), and 325 meshes (95%)Mongolia 3,500tpd Iron Ore Mining and Mineral Processing Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect, 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 Manganese Ore Processing Plant Mining Equipment for Sale

Tailings Wikipedia

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an oreTailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed The extraction of minerals from ore can be done two ways: placer mining, which uses water gold tailing centrifugal separators,US $ 7,000 50,000 / Set, New, Gravity Separator, 1020t/hSource from Shanghai Shicheng Mine Machinery Factory on Alibaba Read More Supply Centrifugal Gold gold tailings machine from canadagold tailing centrifugal separators Joniatuinen1) High recovery rate: Through our test, the recovery rate for placer gold can be 98% or more, for rock gold, the recovery rate could reach 97% when the feeding size is below 004mm 2) High efficiency: STLB60 Gold Concentration Separator has a capacity of 1530TPH, and STLB100 Gold Concentration Separator has a capacity of 60100TPHOnly one machine could give you such a high capacity and Gold Centrifugal Concentrator Gold Tailings Centrifugal STLB Gold Concentration Separator is kind centrifugal concentration equipment It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation It is also used to recover gold from the old tailings Since 1985, three models of Gold Concentration Separator have been developed99% Recovery Ratio Gold Mining Centrifugal Separators iso 9001 ce certified centrifugal slurry pump for ball mill Xinhai® Galigher 1000 Series Xinhai Group The Galigher Series 1000 horizontal end suction centrifugal pump for abrasive and as well as draining slurry from the pump to prevent freezing or corrosion after flushing iso 9001 ce certified centrifugal slurry pump for ball mill

Dry Magnetic Separator, Magnetic Separator Working

3, Under the condition that the grade of the dry tailings is equal to or even lower than that of conventional magnetic roller or conventional dry separator, for highgrade and lean magnetite with different features, by adjusting corresponding technical parameters and structure, about 10%30% tailings discharging and about 10%87% of