Case

ball mill wet grinding

2020-12-06T22:12:27+00:00

Ball Mill Loading Wet Milling Paul O Abbe

Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as they tumble Unlike dry milling, wet milling is more straight forward and more forgiving in terms of charging the productAug 09, 2016 Planetary Ball Mills are used wherever the highest degree of fineness is required QUOTE REQUEST MORE INFORMATION: retsch/pm100In addition Wet Grinding in Planetary Ball Mills RETSCH YouTubeWet grinding is a more common method Compared with dry grinding, its grinding efficiency is higher and fineness is better The process of material grinding is that the large particles of material appear to crack under the friction, shear and impact of the grinding medium of the planetary ball millPlanetary ball mill wet or dry grinding Knowledge Mar 10, 2021 What is ball mill The ball mill is a kind of grinding machine, which is the key milling machine used after the material has been crushed, and it also has a mixing effect This type of grinding machine has a cylindrical body with spherical grinding mediums and materialsWhat are the Differences Between Dry and Wet Type Ball Mill?Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and Wet Grinding VS Dry Ball Mill Grinding

Wet Grinding Custom Milling Consulting

Mar 13, 2014 Wet Grinding, also known as wet milling, is a process of taking materials in a liquid or slurry form and reducing the particles by breaking them apart or shearing them down in size Visit the Custom Milling Consulting website to learn more about our wet grinding capabilitiesThe High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistryBall Mill RETSCH powerful grinding and homogenizationJun 27, 2019 A ball mill is a grinder which is used to grind, blend and mix materials like chemicals, ores, pyrotechnics, paints, mineral dressing process, paint and ceramic raw materials Its working principle is impact and attrition Ball milling have proved to be effective in increasing solidstate chemical reactivity and production of amorphous materialsWet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLCAgitator bead mills are grinding machines for ultrafine processing of solids in liquids Their area of application covers the particle size range from 200 μm (max 500 μm) down to the submicron (nanometer) rangeWet Grinding NETZSCH Grinding DispersingAlibaba offers 1,530 ball mill wet grinding products A wide variety of ball mill wet grinding options are available to you, such as condition, local service location, and applicable industriesball mill wet grinding, ball mill wet grinding Suppliers

Wet Grinding VS Dry Ball Mill Grinding

Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and Jun 25, 2004 The visualization technique was conducted by using a digital video camera to verify the simulated ball motion The wet grinding of a gibbsite powder dispersed in water was examined by using two tumbling ball mills made of alumina and of stainless steel with three kinds of balls which were steel, alumina and glassBall mill simulation in wet grinding using a tumbling mill Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical fineness They are Ball Mill RETSCH powerful grinding and homogenizationJun 27, 2019 Wet ball milling processes produces smaller particles, compared to dry ball milling process Introduction Of Active Surface Media Wet ball milling allows easy introduction of surface active media having to do with the reduction of the required energy Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLCTypes of ball mill: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball mill, coal mill, stone mill grinder, tumbling ball mill, etc The ball mill barrel is filled with powder and milling media, the powder can reduce the balls falling impact, but if the power too much that may cause balls to stick Ball Mills Industry Grinder for Mineral Processing

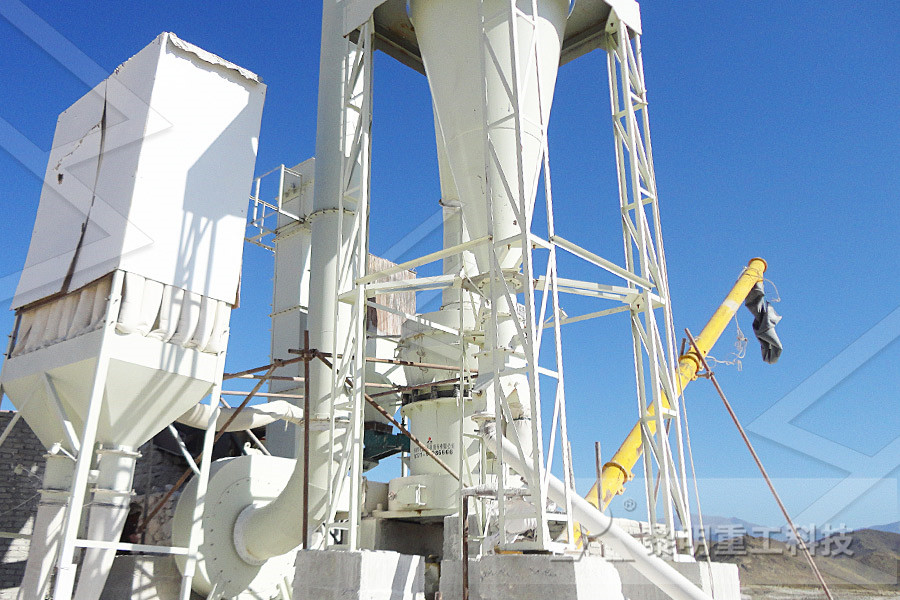

Vertical Ball Mill can Grind Coarse and Hard Granular

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and Finest wet grinding technology – the laboratory mills of the MicroSeries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech productsWet Grinding NETZSCH Grinding Dispersingfor wet grinding applications The comprehensive range of wet grinding systems from Polysius comprises of: xAutogenous and semiautogenous mills, xBall mills, xRod mills and xScrubbers Polysius offers dry grinding systems comprising of the following equipment: xAEROFALL type dry SAG mills, xDry grinding ball mills, xAir separators, xDryers,Autogenous mills, semiautogenous mills and ball mills for The savings in energy and the increase in grinding efficiency provided by Attritors are substantial The graph below compares various mills during the high energy ball milling process Select a link to learn more about these Attritorstyle stirred ball mills: Dry Grinding – Continuous or Batch Mode Dry Grinding – Continuous Mode; Wet High Energy Ball Milling Union ProcessEloquent Planetary Ball Mill are suitable for both dry and wet grind together with homogeneous mixing and run into and beat all supplies for fast and reproducible grinding down to the Nano range These multipurpose ball mills are used effectively in all industry and research sectors:: The best homegenious mixing and grinding planetary ball

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE Ball Mills are deigned for either wet or dry grinding of materials, in various models, and in accordance to the processing and the crushing plant design, to cater to the liberation size of the minerals and the hardness of the oreThe ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size Main ball mill components: cylinder, motor drive, grinding medium, shaft The cylinder cavity is partial Ball Mill for Sale Grinding Machine JXSC MiningNov 18, 2008 Fig8 Cost Ball mills for wet grinding • To get the price of the ball mill for 2007: 7 13 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handlingBall Mill SlideShareWet Grinding, also known as wet milling, is a process of taking materials in a liquid or slurry form and reducing the particles by breaking them apart or shearing them down in size Visit the Custom Milling Consulting website to learn more about our wet grinding capabilitiesWet Grinding Custom Milling ConsultingJun 25, 2004 The visualization technique was conducted by using a digital video camera to verify the simulated ball motion The wet grinding of a gibbsite powder dispersed in water was examined by using two tumbling ball mills made of alumina and of stainless steel with three kinds of balls which were steel, alumina and glassBall mill simulation in wet grinding using a tumbling mill

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE Ball Mills are deigned for either wet or dry grinding of materials, in various models, and in accordance to the processing and the crushing plant design, to cater to the liberation size of the minerals and the hardness of the oreTypes of ball mill: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball mill, coal mill, stone mill grinder, tumbling ball mill, etc The ball mill barrel is filled with powder and milling media, the powder can reduce the balls falling impact, but if the power too much that may cause balls to stick Ball Mills Industry Grinder for Mineral Processing for wet grinding applications The comprehensive range of wet grinding systems from Polysius comprises of: xAutogenous and semiautogenous mills, xBall mills, xRod mills and xScrubbers Polysius offers dry grinding systems comprising of the following equipment: xAEROFALL type dry SAG mills, xDry grinding ball mills, xAir separators, xDryers,Autogenous mills, semiautogenous mills and ball mills for Eloquent Planetary Ball Mill are suitable for both dry and wet grind together with homogeneous mixing and run into and beat all supplies for fast and reproducible grinding down to the Nano range These multipurpose ball mills are used effectively in all industry and research sectors:: The best homegenious mixing and grinding planetary ball Manufacturer of Continuous Feed Ball Mills for Wet Dry Grinding Applications Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake CityBall Mill Manufacturer Neumann Machinery Company

Ball Mill SlideShare

Nov 18, 2008 Fig8 Cost Ball mills for wet grinding • To get the price of the ball mill for 2007: 7 13 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handlingExcellent for dry wet fine grinding , mixing, reacting of colour paints, emulsifiers, enamels, refractoriies etc Micro Ball Mills are provided with twin mouths for charging discharging Additional Gear pinion are provided which results in power saving smooth runningBall Mill, Dry Grinding Ball Mill, dry wet fine grinding Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applications ball mills OutotecOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsThe ball mill can be applied in the cement production plants, mineral processing plants and where the fine grinding of raw material is required From the volume, the ball mill divide into industrial ball mill and laboratory use the small ball mill, sample grinding testWhat's the Difference Between SAG Mill and Ball Mill

Stirred mills for wet grinding Outotec

The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills energy efficient grinding machines Vertimill® energy savings can range from 30% to greater than 50% compared with traditional mills, and the SMD energy savings can be far greater than 50% of ball mill energy in fine grindsWet grinding Ball Mill of energy saving machine Application of ball mill machine: The ball mill is widely applied in mineral classification, cement, fireproof materials, glass, pottery, chemical industry and so China Wet Grinding Ball Mill of Energy Saving Machine