Case

working of raw mill in cement plant

2022-04-26T07:04:04+00:00

Raw Mill In Cement Plant,Cement Making Plant

Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant Sep 23, 2018 This is the practical demonstration of how a raw mill operator puts the raw mill of a cement mill in operation by using Siemens PCS7 DCS OS panel This raw mRaw mill operation in cement plant (Siemens PCS7 OS panel thermodynamic analysis of raw mill in cement iopscience preparation unit in a in nigeria using actual operating data the process model is based on a plant with capacity of 240,000 kg Get Priceworking of raw mill in cement plant13 rows Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary Raw Mill,Raw Mill In Cement Plant

Rawmill Wikipedia

A raw mill is the equipment used to grind raw materials into " rawmix " during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millDec 01, 2006 In order to produce raw materials preparation, clinker and rotary kilns are widely used in cement plants The objective of this study is to perform energy and exergy analysis of a raw mill (RM) and raw materials preparation unit in a cement plant in Turkey using the actual operational data The RM has a capacity of 829 tonmaterial hourlyEnergy and exergy analyses of a raw mill in a cement Jun 01, 2012 The raw mill considered in this study is located in a cement plant located in Sanliurfa, Turkey The plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tons/h The mill diameter is 4230 mm and the grinding chamber length is 10,950 mm (Table 1)Reducing energy consumption of a raw mill in cement Depending on its characteristics, the raw material needed for the cement production process is quarried by blasting, hydraulic excavators or ripping A wide range of crushing plants – depending on the material’s properties and type of extraction – can be used for breaking the extracted raw material to the size required by the raw millRaw material preparation From the quarry to raw meal Overlooked broken tooth was replaced A significant damage to the raw mill dynamic separator was prevented By fixing a small problem ahead of time, a greater problem causing shutdown and lost production was eliminated € 10,00030,000 of damage prevented – 1 day production loss of this millCement Plant: Raw Mill Separator • SAMSON

Reducing energy consumption of a raw mill in cement

Jun 01, 2012 In this study, the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is investigated Effects of weather conditions, moisture content of input materials, and the use of an external hot gas supply facility on the performance of the raw mill are studiedJun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material griThe OK™ mill the most reliable and efficient mill for The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation In 2017, introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement OK™ mill The most reliable and efficient mill for raw and Raw Mill Fan Dunbar Cement At Tarmac (Dunbar cement plant, UK), their existing Raw Mill fan was replaced with an enhanced Howden design in 2007 If you Cement Production Cement HowdenJun 05, 2020 The scope of supply includes engineering, equipment and installation of a new OK 484 Raw Mill with Condition Monitoring System, and an ECS/ProcessExpert system The mill shares the same gearbox design as ’s OK Cement Mill, which was installed at the plant in 2004 to Supply OK Raw Mill to CalPortland Plant

(PDF) PROCESS AUTOMATION OF CEMENT PLANT

C15 transferred the raw materials to the vertical roller mill (VRM) as the raw materials should be finishground before being fed into the kiln for clinkering This process is done in the VRM The raw materials are simultaneously dried using hot air in order to get good quality cementAug 30, 2012 Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale, fly ash, mill scale and bauxite These raw materials are directly brought from other sources because of small requirementsCement Manufacturing Process Phases Flow Chart Mono Chamber Raw Mill Ball Charge Design Hi experts, I want to design a ball charge for a monochamber raw mill in a white cement plant and wanted to know your opinion about it The raw material is preground by to a hammer crusher and after separation by a third generation separator the course material is fed to the monochamber raw millMono Chamber Raw Mill Ball Charge Design Page 1 of 1Raw MillHoppers Cement Plant 3D, formats DWG, 3d cement design hoppers industrial, ready for 3D animation and other 3D projectsRaw MillHoppers Cement Plant 3D CGTraderTransporting Raw Material Typically, a cement plant is located adjacent to or very near a quarry Raw material must be transported from the quarry into the cement plant and eventually into large storage hoppers The mode of transportation is generally via conveyors, Lubrication Strategies for the Cement Industry

Cement manufacturing components of a cement plant

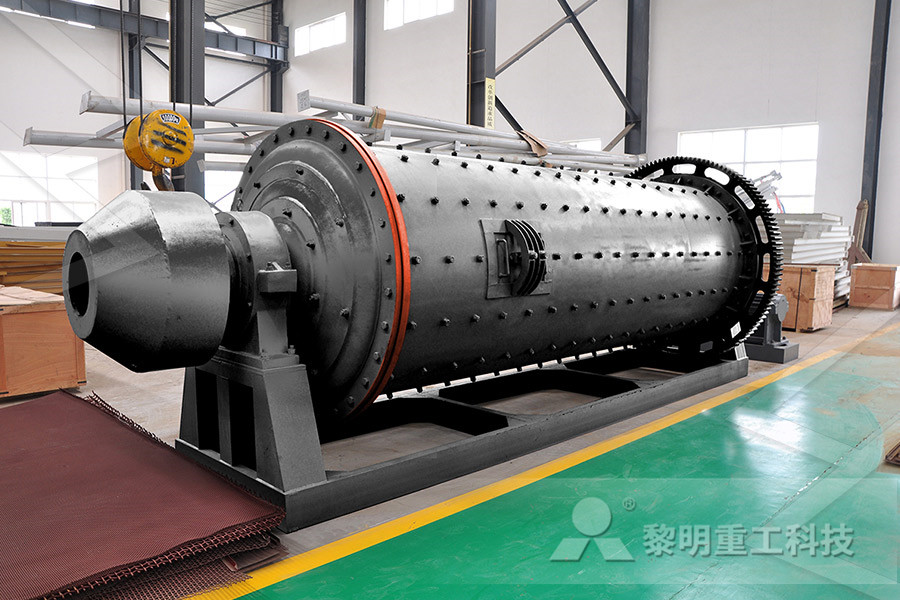

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pagesBall mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%Coal Mill in Cement Plant Vertical Roller Mill Air Greenfield kiln, inline kiln/raw mill, or raw material dryer means a kiln, inline kiln/raw mill, or raw material dryer for which construction is commenced at a plant site (where no kilns and no inline kiln/raw mills were in operation at any time prior to March 24, 1998) after March 24, 1998 Hazardous waste is defined in §2613 of this chapterPortland Cement Manufacturing Industry NESHAP US: Phoenix Industrial will install the raw mill for Denmarkbased ’s raw mill upgrade of CalPortland’s integrated Mojave cement plant in California The company said that it will conduct civil, concrete, structural steel, mechanical and electrical work on the project Mobilisation of crews to the site is due to begin in March 2021 with commissioning scheduled for December 2021Phoenix Industrial wins CalPortland Mojave cement plant Overview This ball mill is mainly used for grinding raw materials and final products in cement plant It can be replaced by vertical raw mill It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industriesRaw Material Ball Mill

Vertical roller mill for raw Application p rocess materials

Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationIn this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Performance Evaluation of Vertical Roller Mill in Cement Automated sample preparation in a cement plant Part I: From quarry to the raw mill Abstract This application note is the start to a series of publications to explain the importance of correct sampling and sample preparation within the cement production process Topics covered by this application noteAutomated sample preparation in a cement plant Part I Aug 04, 2008 Animation of the OK Vertical Roller Mill which can be used for Portland cement, slag and blended cement ATOX® raw mill Duration: 6 How to build a cement plant Duration: 12 OK Mill YouTubeCement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln Wikipedia

BASIC CEMENT PLANT LAYOUT – Process Cement Forum – The

Jul 04, 2020 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powderThe scope of supply includes engineering, equipment and installation of a new OK 484 Raw Mill with Condition Monitoring System, and an ECS/ProcessExpert system CalPortland’s Mojave Cement Plant The mill shares the same gearbox design as ’s OK Cement Mill, which was installed at the plant to Supply OK Raw Mill to CalPortland PlantThe cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cementraw mix, shorten the length of rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, which promote the Preheater In Cement Plant, Cyclone Preheater, Cement work: Case of Hamma Bouziane cement plant (A lgeria)’, Safety Science, Vo l 76, pp 145 –150 Tomar, MK 2014, ‘Study of Occupational Health, Safety and Environmental Aspects in Major Cement(PDF) OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRYJan 25, 2016 The mercury concentrations in the flue gas after the raw mill and before FF of the raw mill in Plant 2 were tested to be 167 ± 122 and 223 ± 56 μg/m 3, respectivelyThe mercury mass flows in the raw mill system are given in Table 2The proportions of mercury input from flue gas emitted from the kiln tail reached 837% and 685%, much higher than that of the raw materials, which were 12 Characteristics of mercury cycling in the cement

Phoenix Industrial wins CalPortland Mojave cement plant

US: Phoenix Industrial will install the raw mill for Denmarkbased ’s raw mill upgrade of CalPortland’s integrated Mojave cement plant in California The company said that it will conduct civil, concrete, structural steel, mechanical and electrical work on the project Mobilisation of crews to the site is due to begin in March 2021 with commissioning scheduled for December 2021Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc Application : Cement Plant, ClCement Vertical Roller MillRaw Mill Exhaust Fans Raw mill exhaust fans or stack fans are also called as dedusting fans In cement industry raw mill exhaust fans handle 22 ton of exhaust gases for the production of 1 ton of clinker Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along Process Fans Used in Cement Industry Reitzindia