Case

planetary ball mill with tungsten carbide vials

2023-02-16T01:02:39+00:00

Planetary Ball Mill 911Metallurgist

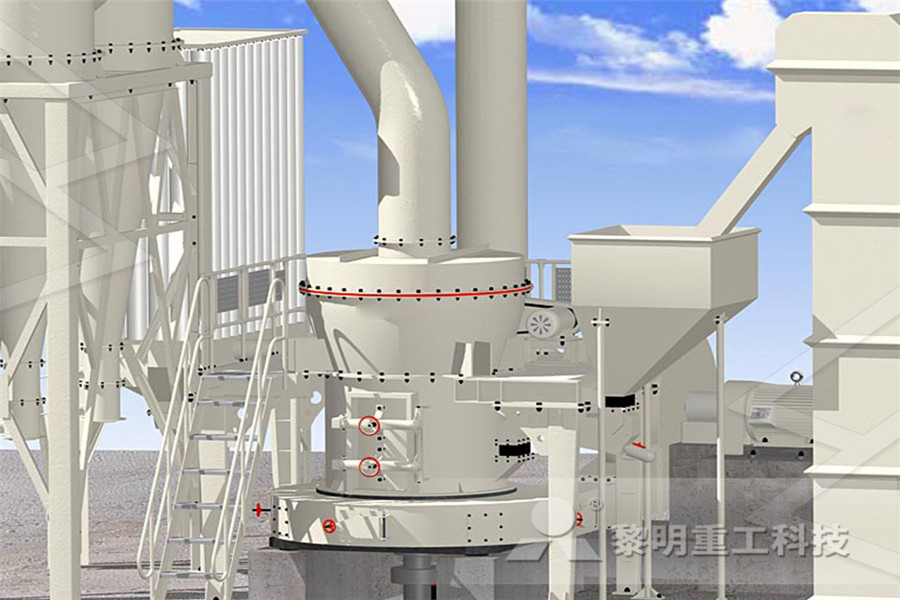

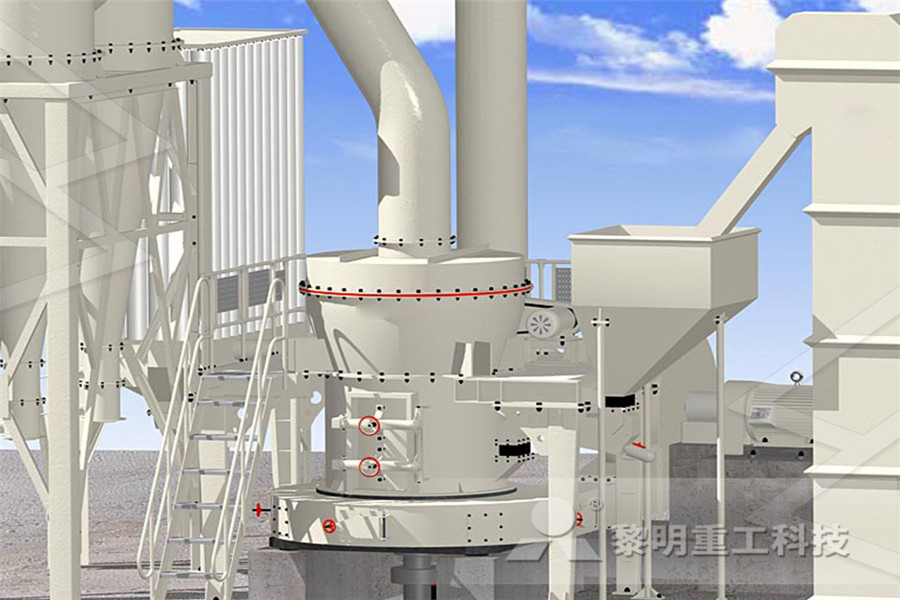

Planetary Ball Mill Working Principle Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centrePlanetary Ball Mill With Tungsten Carbide Vials Planetary Ball Mill With Tungsten Carbide Vials T130x enhanced superfine grinding mill is a newly designed grinding mill based on the former patent product tgm super pressure trapezium mill according to market investigation and careful statistics and analysis of use and suggestions from our planetary ball mill with tungsten carbide vialsJan 01, 2015 High energy milling was performed using a planetary ball mill (Insmart Systems, Model: BGD 2009, Hyderabad, India) The milling media consisted of tungsten carbide (WC) and tungsten (W) balls 8 mm in diameter and 500 ml tungsten carbide bowlsHigh energy milling on tungsten powders ScienceDirectPlanetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 RETSCH highest finenessPlanetary Ball Mills How they work In Planetary Ball Mill the milling cups rotate as planets in 2 positions, rotating around themselves and rotating around disk center This type of Rotating causes shooting of Milling Balls in all directions and making powder of Materials in Micron and Nanometer in optimum time Application: • Milling and Reducing of Particle size down to Nanometer Planetary Ball Mills LabTechniche

planetary ball mill with tungsten carbide vials

Planetary Ball Mill With Tungsten Carbide Vials Planetary Ball Mill With Tungsten Carbide Vials T130x enhanced superfine grinding mill is a newly designed grinding mill based on the former patent product tgm super pressure trapezium mill according to market investigation and careful statistics and analysis of use and suggestions from our Ball Mill found in: Planetary Ball Mill, High Energy Ball Mill Emax, GearDrive 04Liter Planetary Ball Mills, Ball and Vial Sets, GearDrive 12Liter Tungsten CarbideLined Vial Set SPEX CertiPrep center cylinders, and two 5/16 in (79 mm) tungsten carbide ballsBall Mill at Thomas ScientificPlanetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 RETSCH highest finenessYou’ll also find materials including tungsten carbide, stainless steel and agate Grinding balls, otherwise known as milling media are available in a variety of sizes, ranging from kg to tons in measurement 04L (4 x 100ml or 4 x 50 ml) Bench Top Mini High Energy Vertical Planetary Ball Mill $ 3,995 00 05 L (500 ml) Nylon Roller Mill Ball Milling Machine MSE Supplies LLCThe milling process carried out in planetary mills is faster and more efficient For instance, during the production of fine WC powder it is an usual practice to mill tungsten carbide powder in a ball mill for 130 hours In a planetary mill characteristic time of WC milling down to submicron level ranges from 15 to Highenergy planetary mills – milling equipment of the

planetary ball mill for sale eBay

108 results for planetary ball mill Save this search A set of 4X50ml Tungsten Carbide Milling Jars for Planetary Ball MillPBM04 Brand New $2,40000 From Canada or Best Offer Free shipping Watch; S p o n s o r e d 2L Vertical Small Lab Planetary Ball Mill Machine Portable Ball Grinding MillsPlanetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowlsPlanetary Mills – fritschde1 mm Spherical Tungsten Carbide Milling Media Balls Tungsten Carbide GrindingMilling Media Balls Specifications Highly polished tungsten carbide ball mill grinding media balls highly wearresistant and resistant to acid and alkali High hardness can meet the vast majority of metal powder crushing and refining They are extensively applied to in the fields of Metallurgy Ceramics Electronics Light ball milling of tungsten carbide in ethiopiaView our Mills products at Fisher Scientific Fisher Scientific, Bishop Meadow Road, Loughborough, Leicestershire, LE11 5RGMills Fisher ScientificA planetary ball mill, PM 100, with tungsten carbide balls of diameter 95 mm was used The vial containing 62 g of powder and 620 g of tungsten carbide balls in the ratio 1:10 (wt/wt) was utilized Toluene was used as a wet grinding media in order to reduce the heat produced during ball milling EFFECT OF MILLING TIME ON PRODUCTION OF ALUMINIUM

Planetary Ball Mills LabTechniche

Planetary Ball Mills How they work In Planetary Ball Mill the milling cups rotate as planets in 2 positions, rotating around themselves and rotating around disk center This type of Rotating causes shooting of Milling Balls in all directions and making powder of Materials in Micron and Nanometer in optimum time Application: • Milling and Reducing of Particle size down to Nanometer 212 Planetary ball mills Planetary ball milling machines have higher production capacities than the SPEX mills, because larger vials can be used In these mills, the vials are fixed on a rotating support disk, while they rotate around their own axes following a special drive mechanismThis content has been downloaded from IOPscience Please tungsten carbide ball mill vials tungsten carbide ball mill vials Mixer Yajie Chen et al The brittle ribbons were ball mill ed using tungsten carbide vials and stainless steel balls in an » Learn More ball mill and mixer for tungsten ball mill fractional filling; planetary ball mill msk sfm 1; Tungsten Carbide Ball Mill from planetary ball mill with tungsten carbide vials – Grinding Tungsten Carbide planetary Mill Jar Brand: TENCAN Applications: Tungsten carbide ball mill jar is used as grinding jar of planetary ball mill matched with tungsten carbide balls, which is suitable for grinding materials in high hardness such as hard alloy powder, diamond powder, and silicon carbide Tungsten Carbide planetary Mill Jar Lab ball mills,Lab Planetary Ball Mills How they work In Planetary Ball Mill the milling cups rotate as planets in 2 positions, rotating around themselves and rotating around disk center This type of Rotating causes shooting of Milling Balls in all directions and making powder of Materials in Micron and Nanometer in optimum time Application: • Milling Planetary Ball Mills LabTechniche

tungsten carbide grinding ball mill, tungsten carbide

Hot sale tungsten carbide grinding jar ball mill jar TC jars laboratory mill for planetary ball mills 50ml 100ml 250ml 500ml US $16490$1350 / Piece 4 Pieces (Min Order)You’ll also find materials including tungsten carbide, stainless steel and agate Grinding balls, otherwise known as milling media are available in a variety of sizes, ranging from kg to tons in measurement 04L (4 x 100ml or 4 x 50 ml) Bench Top Mini High Energy Vertical Planetary Ball Mill $ 3,995 00 05 L (500 ml) Nylon Roller Mill Ball Milling Machine MSE Supplies LLCTungsten Carbide Ball Mill Vials Tungsten carbide ball mill vials marthinusencoa parameters optimiation in the planetary ball milling of introductionball milling is an efficient and simple method tungsten carbide ball mill vials provesprojektdeA planetary ball mill, PM 100, with tungsten carbide balls of diameter 95 mm was used The vial containing 62 g of powder and 620 g of tungsten carbide balls in the ratio 1:10 (wt/wt) was utilized Toluene was used as a wet grinding media in order to reduce the heat produced during ball milling EFFECT OF MILLING TIME ON PRODUCTION OF ALUMINIUM study showed that tungsten carbide vial, alumina mortar, and aluminaceramic vial introduced contamination with several elements They reported that boron carbide mor hand mill, and allagate planetary ballmillContamination introduced during rock sample powdering

Influence of temperature on AC conductivity of

Nanocrystalline CuAlO 2 was synthesized by mechanical alloying of Cu 2 O and αAl 2 O 3 powders in the molar ratio of 1:1 for 20 h in toluene medium with tungsten carbide balls and vials using planetary ball mill The ball milling was carried out at 300 rpm with a ball According to the material, ranging from 04 mm to 3 mm for small media mills, up to 3mm to 20mm for planetary ball mill, and up to 20mm to 50mm for ball mills: Grinding Ball Types: High precision ball, Semiprecision ball, sintered rough ball 10mm, 12mm, 14mm, 16mm, 18mm, 20mm tungsten carbide ball Miller™ Tungsten Carbide Grinding Media Balls MillercarbideView our Mills products at Fisher Scientific Antibodies Protein Biology Antibody Production PurificationMills Fisher ScientificMay 14, 2018 Nanocomposite of (ZnO)1−x(C)x in two different ratio were prepared by high energy Fritsch Pulveristte—P5 planetary ball mill using tungsten carbide vials and balls Structural Photocatalytic Activity of High Energy Ball Mill Derived A wide variety of ball mill tungsten carbide options are available to you, such as thread turning tool, external turning tool You can also choose from 3 years ball mill tungsten carbide, as well as from gs, epa, and csa ball mill tungsten carbide, and whether ball mill tungsten carbide ball mill tungsten carbide, ball mill tungsten carbide

Structural and magnetic properties of ballmilled

about 2 h were then milled in a planetary ball mill operating at a speed of 250 rpm using tungsten carbide vial and a ball to powder ratio of 20:1 To avoid oxidation during milling, the powders were milled in ethanol Test samples were taken after every 10 h of milling The milling The widest ball mills in RETSCH’s comprehensive range of ball mills comprises High Energy Ball Mills, Planetary Ball Mills and Mixer Mills Whereas the Mixer Mills are used for dry/wet/cryogenic grinding and homogenizing small sample volumes, the Planetary Ball Mills meet and exceed all requirements for fast and reproducible Wet grinding Dry grinding Grind size Adapters for disposable vials Ball Mills Retsch GmbH PDF Catalogs Technical