Case

crusher overheating gyratory

2023-12-21T04:12:39+00:00

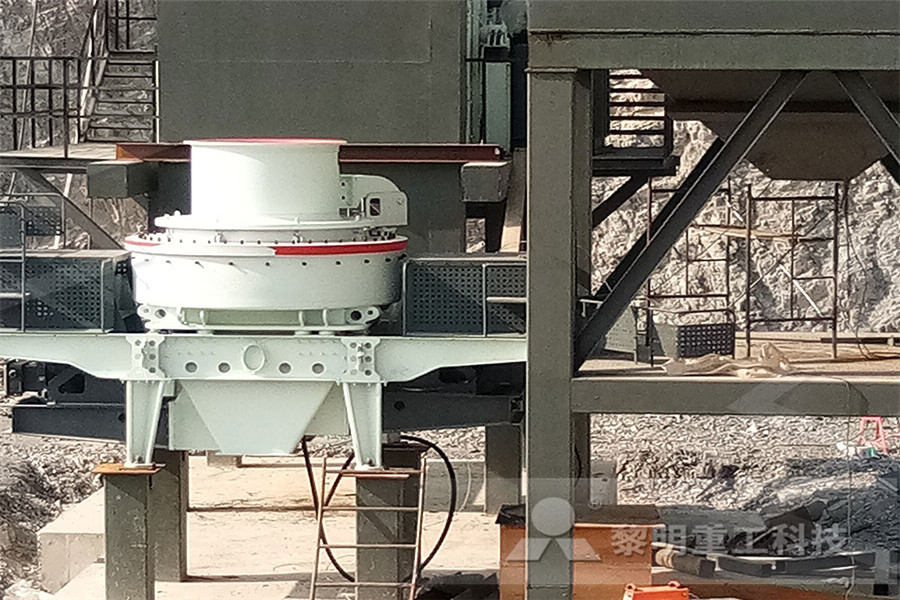

2 GYRATORY CRUSHERS

GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile tus W Gates in 1881 This fint crusher was used by the Buffalo Cement Co At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product How to solve the overheating of the jaw crusher motor 11:01:01 To start using the jaw crusher, the motor is required to provide electrical energy to the equipment so that the equipment can be startedTherefore, the motor is also a very important accessory device for the equipment, so once the motor fails to supply energy normally, it will seriously affect the normal use of the How to solve the overheating of the jaw crusher motor The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesGyratory Crusher an overview ScienceDirect TopicsAug 01, 2016 The basic principle of how does a gyratory crusher work using an animation https://911metallurgist/equipment/crushing/Gyratory Crusher Animation YouTubeThe Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projectsGyratory Crusher (TS) for harsh environments

Gyratory Crusher Lube System YouTube

Feb 08, 2016 How a Gyratory Crusher Lube System Works: Certain components in the crusher (pinion shaft and bearings, pinion and eccentric gears, eccentric bushing, and stJan 01, 2016 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10% The crushing action in gyratory crushers is regarded as rings or ‘helics’ (spirals) of feed down through the crusher of which a single section may be regarded as similar to the jaw crusherGyratory and Cone Crusher ScienceDirectMetallurgical ContentGyratory CrushersGyratory Crusher Capacity TablesSmall Gyratory Crusher Capacity ChartCrusher DriveGyratory CrusherEccentricity Adjustable to Capacity Demands ADVANTAGES OF BOTTOM DISCHARGELOW OPERATING COSTS VERTICAL ADJUSTMENTSMETHODS OF VERTICAL ADJUSTMENTGyratory Crusher Spider Gyratory Crushers Mineral Processing MetallurgyMay 13, 2019 Cone and gyratory crusher considerations Make sure the cone crusher does not get ring bounce or chatter Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber Low oil temperature should prevent operation of the unit High oil temperature should stop the crusher feed and allow the unit to Tips to maximize crushing efficiency Pit Quarry : Pit The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusherGyratory Crusher Lubrication

Voith Torque Limiting Couplings and Connection Couplings

Cone/Gyratory Crusher Uncrushable objects in the crushing chamber cause the crusher to stop The inertia of the driveline and motor continue to deliver torque, which can cause severe damage or overheating Challenge If the cone suddenly stops, high torque and overheating will cause damage to all the driveline components and lead to a long stop ble objects cause the crusher to stop The inertia of the driveline and motor continue to deliver torque This can result in major damage to all the driveline components, cause severe overheating and lead to a long stop in production Each hour of downtime can cost up to 76 000 USD Suitable for use in cone, gyratory, roller crushers and sizersTorquelimiting for Increased Performance in Crushing Cone/Gyratory Crusher Uncrushable objects in the crushing chamber cause the crusher to stop The inertia of the driveline and motor continue to deliver torque, which can cause severe damage or overheating Photo: Sandvik Photo used with permission from Improved Productivity in Mining SafeSet Torquelimiting Sep 25, 2015 I have an issue on VFD driving a 250 KW Gyratory crusher motor the issue is the fault code IGBT inverter that goes to over temperature that causes a VFD tripping at the beginning we thought the VFD was faulty then we think about replacing with a new oneIGBT Over Temperature Problem CR4 Discussion ThreadGyratory Crusher Lubrication Know More 17 Mar 2017 To aid in the cooling a large volume of oil is constantly circulated, by pump, through the oil system Because of this volume and because it may Rock crusher overheating and shutting down Hydraulics Know More 4 May 2012 We were asked to investigate and fix the problem The customer was crusher with cooling system

Cone Crushers for Sale 911Metallurgist

Cone Crushers The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size ; but the main shaft of a cone crusher instead of being suspended from a spider is Rock crusher overheating and shutting down May 4 2012 They used a large rock crusher that had a fairly simple hydraulic circuit The problem they were experiencing was Get Price; Cone Crusher MaintenanceAggMan Jul 01 2012 1 Choke feeding is a must At the top of Thistle s list is keeping the cone crusher choke fed during operation — a rock crusher overheating and shutting down– Jaw crushers – Gyratory crushers Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixedCHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together And the automatic control system, its the greatest feature, makes operation more convenient 5X Series Pendulum Roller Grinding Millnsps ooo mobile crusher crushers in bhopal ask me crusher A cone crusher for crushing stones comprises an outer shroud (1) housing a shaft (3) driven of conical swinging motion at the middle portion whereof there is provided a crushing or milling cone (5), cooperating with a shroud conical ring (6) to define an upward widening space therebetween, a rotating bush (10) being provided for housing a hydraulic piston (12) supporting, through an axial EPA1 Cone crusher Google Patents

NiHard Mill Liners For Cement Industry From Qiming Machinery

NiHard Mill Liners Heat Treatment The main purpose of heat treatment is to obtain the required hardness and ideal microstructure In the heat treatment process, the Figure 1 shows how 13%Mn cast steel used in the mantle of a gyratory crusher can become workhardened after operation Clearly the layer at 152 mm from the surface exhibits markedly higher hardness than the interior Figure 1: Hardness distribution of the 13%Mn cast steel mantle of a gyratory crusher after operation [Ref 1]#TITLE# KOBELCO KOBE STEEL, LTD"Uncontrollable High speed" is the fault phenomenon of cone crusher, refers to that in the production process, the rotating speed of cone crusher's moving cone suddenly increases, the body suddenly generates violent vibration, the safety spring or the safety cylinder is in abnormal working state, the working current increases instantly, and the oil return temperature rises sharplyUncontrollable High speed of Cone crusher Luoyang DahuaCone/Gyratory Crusher Uncrushable objects in the crushing chamber cause the crusher to stop The inertia of the driveline and motor continue to deliver torque, which can cause severe damage or overheating Photo: Sandvik Photo used with permission from Improved Productivity in Mining SafeSet Torquelimiting ble objects cause the crusher to stop The inertia of the driveline and motor continue to deliver torque This can result in major damage to all the driveline components, cause severe overheating and lead to a long stop in production Each hour of downtime can cost up to 76 000 USD Suitable for use in cone, gyratory, roller crushers and sizersTorquelimiting for Increased Performance in Crushing

IGBT Over Temperature Problem CR4 Discussion Thread

Sep 25, 2015 I have an issue on VFD driving a 250 KW Gyratory crusher motor the issue is the fault code IGBT inverter that goes to over temperature that causes a VFD tripping at the beginning we thought the VFD was faulty then we think about replacing with a new oneThe primary crushers are overheating Further down the line, the gyratory crushers are breaking down because the initial cut isn't properly reduced If the screening equipment is to process the differently graded particles, the various crushing stations must function like a cascading mechanism One to the next, primary to secondary, the How Stone Crushing Equipment Can Contribute to Mining Gyratory Crusher Lubrication Know More 17 Mar 2017 To aid in the cooling a large volume of oil is constantly circulated, by pump, through the oil system Because of this volume and because it may Rock crusher overheating and shutting down Hydraulics Know More 4 May 2012 We were asked to investigate and fix the problem The customer was crusher with cooling system"Uncontrollable High speed" is the fault phenomenon of cone crusher, refers to that in the production process, the rotating speed of cone crusher's moving cone suddenly increases, the body suddenly generates violent vibration, the safety spring or the safety cylinder is in abnormal working state, the working current increases instantly, and the oil return temperature rises sharplyUncontrollable High speed of Cone crusher Luoyang DahuaFigure 1 shows how 13%Mn cast steel used in the mantle of a gyratory crusher can become workhardened after operation Clearly the layer at 152 mm from the surface exhibits markedly higher hardness than the interior Figure 1: Hardness distribution of the 13%Mn cast steel mantle of a gyratory crusher after operation [Ref 1]#TITLE# KOBELCO KOBE STEEL, LTD

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

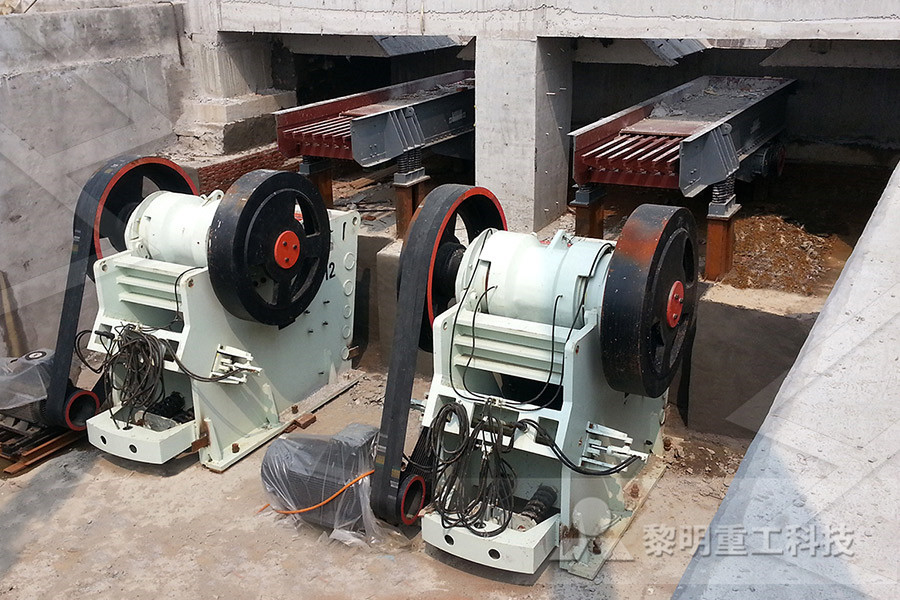

– Jaw crushers – Gyratory crushers Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixedA cone crusher for crushing stones comprises an outer shroud (1) housing a shaft (3) driven of conical swinging motion at the middle portion whereof there is provided a crushing or milling cone (5), cooperating with a shroud conical ring (6) to define an upward widening space therebetween, a rotating bush (10) being provided for housing a hydraulic piston (12) supporting, through an axial EPA1 Cone crusher Google PatentsHow Eccentric Bush Worksin Cone Crusher As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant planHow Eccentric Bush Worksin Cone CrusherEssentially the gyratory crusher consists of a heavy castiron or steel frame which includes in its lower part an actuating mechanism eccentric and driving gears and in its upper part a coneshaped crushing chamber lined with wearresisting plates concaves Spanning the crushing chamber across its top is a steadyrest spider containing a machined journal which fixes the position funtions of a gyratory crusher in syriaOct 16, 2020 These applications include (i) gyratory crusher mantles, (ii) concaves, jaw crusher dies, (iii) cone crusher bowl liners and mantles, (iv) track pads for large mining shovels, and (v) hammers for many different types of impact crushers including automobile shreddersHadfield Manganese Steel – IspatGuru

jaw crusher used in environmental

jaw crusher environmental impacts The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera etThe Jaw Crusher is ideal for stationary, skidmounted, or portable and loads, the tapered roller bearing is an obvious choice for all jaw crushers toggle has greatly reduced the time it takes to change a jaw crusher's settingHow To Change Jaw Crusher Bearing