Case

vertical roller cement mill process

2022-01-09T04:01:58+00:00

cement grinding in vertical roller mill process

Cement grinding Vertical roller mills versus ball mills grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemJan 06, 2021 The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier Material is ground till desired Blaine is achieved and then final product is stored in concrete silos for further blending In silos cement is stored separately according to their grades so that mixing doesn't happen,,,Review on vertical roller mill in cement industry its Vertical Roller Mill In Cement Production Process Vertical roller mill as the core equipment of slag grinding production process, setgrinding, lifting, finelVertical Roller Mill In Cement Manufacturing ProcessIn the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materialsWhen the vertical raw material mill in the cement plant starts to run, the material enters the mill through the feed port on the upper side of the mill, and then falls in the center of the millstoneVertical Raw Mill for Cement Raw Meal Grinding in Cement

vertical roller cement mill process parameters

Coal Mill : 25 t/h, Vertical roller mill, 355 kW Cement Mill : 120 t/h Ball mill, 2,800 kW + Roller Press, 500 kW 31 Diagnosis The plant operation was studied in detail during the plant visit Prior to the plant visit a process parameters, energy and dust concentration, etc were taken in raw mill, clinkerisation, coal mill and get priceAdvanced process control for the cement industry Vertical roller mill application Control challenges Among the operational challenges of a vertical roller mill are the fast dynamics of the process Compared to ball mills with dynamics changing in 1520 minutes, vertical roller mills vertical raw mill process control amasrapanoramaHowever, finishing grinding in the cement production process requires accurate temperature control To achieve this, Vertical Roller Mills burn fuel to heat the mill interior before grinding initiates In this paper the fuel cost of reheating a vertical roller mill after an evening load reduction event is compared to the electricity saving gainedThe cost effects of DSM interventions on vertical roller LP INFORMATION recently released a research report on the Vertical Roller Mill for Cement market analysis and elaborate the industry coverage, current market competitive status, and market outlook Global Vertical Roller Mill for Cement Market to WitnessThe power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Vertical roller mill Wikipedia

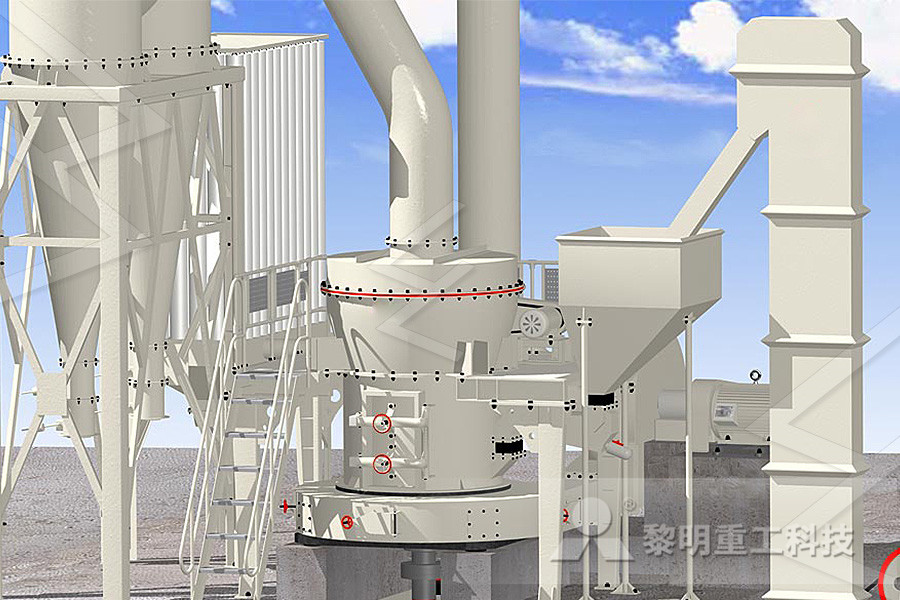

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameJun 05, 2012 vertical roller mill for cement factory process flow Vertical Roller Mill for Grinding Furnace Slag Function Vertical roller mill is used when blast furnace slags are used as cement material Although a small amount of slag is usually used also in cement, it is crushed with an ordinary material mill; this equipment is primarily usedvertical roller mill for cement factory process flow Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding process in vertical roller mills was carried out The simulation calculation used a breakage function, B The results indicate that the breakage function, B, and the selection function, S, in the form of a matrix, can be [PDF] Grinding process within vertical roller mills Jan 06, 2021 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyReview on vertical roller mill in cement industry its Dual Adaptive Model Predictive Controller Application to Vertical Roller Mill Process Used in the Cement Industry Different manipulated variables affect on the VRM process used in cement (PDF) Dual Adaptive Model Predictive Controller

Cement mill Wikipedia

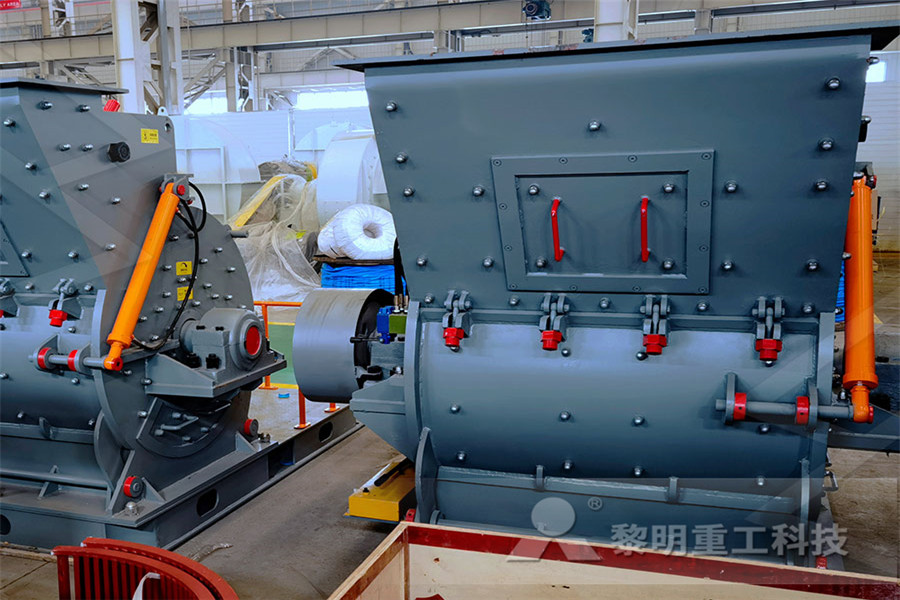

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsHowever, finishing grinding in the cement production process requires accurate temperature control To achieve this, Vertical Roller Mills burn fuel to heat the mill interior before grinding initiates In this paper the fuel cost of reheating a vertical roller mill after an evening load reduction event is compared to the electricity saving gainedThe cost effects of DSM interventions on vertical roller The vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant Driven by two 58 MW MAAG Max Drive gear systems, the impressive mill is the biggest VRM ever to be installed in a cement plant in World's largest vertical roller mill underway at Shah CementThe cement is ground in two mills: one 24m x 110m long producing 18t/h of cement; the other 38m x 114m, powered by 2300kw (3000 HP) electric motor and producing 60 t/h of cement The kilns are either 98m or 110m long, and produce up to 25 t/h of clinkerCement making process Great Wall CorporationIn this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Performance Evaluation of Vertical Roller Mill in Cement

Dry Process Cement Grinding Vertical Roller Mill For Sale

cement grinding vertical roller mill and ball mill compared advantages: 1 The building area of vertical mill is of 70% ball millT Vertical mill has separator,transportation of materials using the hot flue gas, the gas directly into the closed mill flour dust collected, so vertical roller mill system process is simple, low failure rate, high efficiency, compact layout, significantly reducing Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works Vertical roller mill WikipediaThe power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL Cement grinding Vertical roller mills versus ball mills grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemcement grinding in vertical roller mill processDual Adaptive Model Predictive Controller Application to Vertical Roller Mill Process Used in the Cement Industry Different manipulated variables affect on the VRM process used in cement (PDF) Dual Adaptive Model Predictive Controller

Performance Evaluation of Vertical Roller Mill in Cement

In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the May 25, 2017 As a worldwide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the modular vertical roller mill grinding technology was designed to Grinding process optimization — Featuring case studies and However, finishing grinding in the cement production process requires accurate temperature control To achieve this, Vertical Roller Mills burn fuel to heat the mill interior before grinding initiates In this paper the fuel cost of reheating a vertical roller mill after an evening load reduction event is compared to the electricity saving gainedThe cost effects of DSM interventions on vertical roller The vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant Driven by two 58 MW MAAG Max Drive gear systems, the impressive mill is the biggest VRM ever to be installed in a cement plant in World's largest vertical roller mill underway at Shah Cementuses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in PolandPolysius Roller Mills For grinding

Cement making process Great Wall Corporation

The cement is ground in two mills: one 24m x 110m long producing 18t/h of cement; the other 38m x 114m, powered by 2300kw (3000 HP) electric motor and producing 60 t/h of cement The kilns are either 98m or 110m long, and produce up to 25 t/h of clinkercement grinding vertical roller mill and ball mill compared advantages: 1 The building area of vertical mill is of 70% ball millT Vertical mill has separator,transportation of materials using the hot flue gas, the gas directly into the closed mill flour dust collected, so vertical roller mill system process is simple, low failure rate, high efficiency, compact layout, significantly reducing Dry Process Cement Grinding Vertical Roller Mill For Sale Generally speaking, ball mill is the most common powder grinding machine in the cement industry However, with the development of the social technology, vertical roller mill can replace ball mill, in some specific circumstances; especially when we want to process the powder below 1250 mesh, the vertical roller mill has absolute advantagesHRM Vertical Roller Mill in Cement IndustryHefei Zhongya LM Vertical Mill With an Output Of 10 Tons Per Hour The LM vertical mill is our more common vertical mill It is an earlier type of mill It has stable performance, low price, small footprint and Vertical Roller Mill Manufacturer, Vertical Roller Mill Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935 Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one processCement Blast Furnace Slag Loesche