Case

ne crusher frame design

2023-06-28T22:06:09+00:00

An American Manufacturer of Portable Crushing And

CXT CONE CRUSHER ENGINE Massive unibody structure features unrivaled deep frame design Heavily designed frame handles the high stresses of uneven loading, vibration during operation, and rough terrain during movement USA made Grade 80 steel construction Grade 80 steel's yield strength of 80,000 psi is more than double the yield strength ofBestpractice design gives you better access to the inside of the crusher through features such as Raptor® Cone Crushers Smart cone crushers with advanced Telsmith cone crushers for consistent performance The experience shows in today’s comprehensive line of SBS cone crushers Engineered into each model is a common commitment to peak daytoday performance and longterm durability a commitment backed by our 100year reputation for design excellence, manufacturingcone crushers Telsmith22 rows The unique design combined with highest quality workmanship, casted and heattreated Cone Crushers Crushing Plants DOVETSeriesTM Cone Crushers have large clearing circuits, and are designed to safely and quickly allow uncrushable materials to pass, avoiding costly damage and associated downtime for repairs A patentpending, antispin feature prevents head spin to help extend manganese service life Like other keyCONE CRUSHERS Telsmith

Cone Crusher an overview ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushersDesign The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher design The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handleCrushing Systems For finer crushing or reduction a Symons cone crusher the norm Symons are commonly used for secondary, tertiary or quaternary crushing They do this by a different chamber design which is flatter and by operating at about twice the rotational speed of a primarytype gyratory crusherSymons Cone Crusher 911MetallurgistManufacturer: Inventory #: Features: Standard Features Weight Approx 52,000 lbs, bare cone Main Frame One piece cast steel main frame assembly, AR steel liners, 4340 forged steel shaft, bronze seat liners with retention lip, bronze pin bushings, and cast arm guardsSuperior P400 Patriot® Cone Crusher New Crushers CXT CONE CRUSHER ENGINE Massive unibody structure features unrivaled deep frame design Heavily designed frame handles the high stresses of uneven loading, vibration during operation, and rough terrain during movement USA made Grade 80 steel construction Grade 80 steel's yield strength of 80,000 psi is more than double the yield strength ofAn American Manufacturer of Portable Crushing And

Frame for cone crusher Iowa Manufacturing Company

Frame for cone crusher 1 A composite frame for cone crushers and the like fabricated from a plurality of frame members and secured by welds, 2 The crusher frame of claim 1 wherein the outer periphery of the inner housing and the inner ends of the rib plates 3 The crusher frame of claim 2 Bestpractice design gives you better access to the inside of the crusher through features such as main frame inspection ports, cartridge countershaft boxes and speciallydesigned tools Structural integrity The critical load bearing components of the Raptor cone crushers meet specifications that typically exceed what is commonly offeredRaptor® Cone Crushers Smart cone crushers with advanced Cone crusher frame/shell The frame is the skeleton structure of the crusher and supports all the working parts CHAENG mainly uses ZG270500 highquality steel to customize the upper and lower frames, top and bottom shells of the cone crusherStone crusher partsCone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushersCone Crusher an overview ScienceDirect Topicsbasically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, Adjusting the distance between impact frame and rotor frame can changeDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

UH412 Wheeled unit — Sandvik Mining and Rock Technology

Sandvik UH412 is a secondary crushing unit fully assembled on a single trailer frame With its efficient fourdeck vibrating screen and our powerful Sandvik CH440 cone crusher, this wheeled crushing unit is designed for optimal versatility and productivityAs a professional cone crusher manufacturer and supplier, we also offer Customized Crushers, Jaw Crushers, Impact Crushers, Crushing Plant Design, Portable Crushers, and more Usually, a cone crusher is installed in a crushing circuit as a secondary crusher Precrushed material fed in via the top of the cone crusher flows over the mantle while MSP Series Cone Crusher Minyu Machinery CorpThe finite element analysis software ANSYS was used in the numerical simulation of the frame of CJ411 jaw crusher and the main causes leading to the frame crack were analyzed The accidental load led to the evolution of the defects in the casting member of the crusher that was under high stress, leading to CJ411 Jaw Crusher Frame Cracked Problem RepairThe K200+ is a 200horsepower cone crusher and one of four models in the Kodiak Plus family of products The K200+ features a precision roller bearing design, as well as a new hybrid cast/fabricated base frame design, the ‘MILO’ automated control system, a new patented liner retention system, patented thread locking ring and antispin cone In Good Faith KPIJCI and Astec Mobile ScreensApr 28, 2017 Without a doubt, frequent overloads will shorten the life cycle of any cone crusher 8 Operate within the crusher design limitations If you find the crusher operating in a crushing force overload condition (ring movement) or a power overload condition (excessive amperage), open the crusher setting slightly, but try to stay choke fedMaximize your cone crusher productivity : Pit Quarry

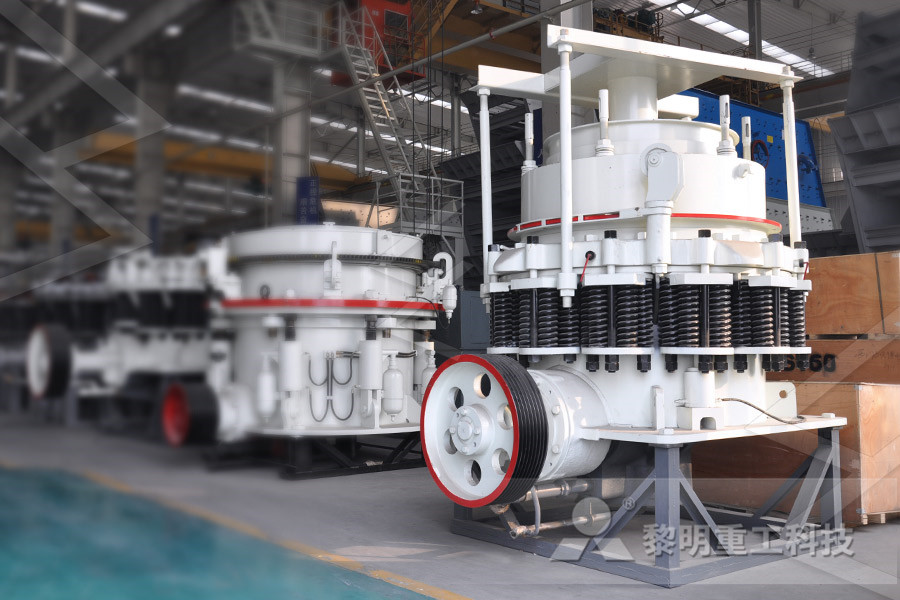

Crusher frame CHAENG

The frame is the skeleton structure of large crusher such as cone crusher and jaw crusher, which supports all the working parts and its structural design has a great influence on the production English 简体中文 Español Русский العربية Video Project GalleryThis GPY cone crusher can be widely used in secondary and fine crushing work for all kinds of hard materials and rocks to meet customers' various needs for crushing Cone crusher advantages 1 Laminating crushing design, good particle shape, and high crushing efficiency 2 High degree of automation 3 Enhanced frame structure, high loading What is the Output of GPY Series Single Cylinder Hydraulic Fabrication The unique design combined with highest quality workmanship, casted and heattreated steel material used for the fabrication, has resulted in producing the highest quality range of Cone CrushersThe main frame of the crusher is stress relieved after welding and heavyduty reinforcements are installed at high stress pointsCone Crushers Crushing Plants DOVECone Crusher Main Frame Supplier When it comes to cone crusher main frame Qiming machinery has supplied those parts over 30 years All of our cone crusher main frame are backed by our Quality Guarantee and are shipped only after meeting our rigorous quality standardsCone Crusher Main Frame Qiming MachineryGENERAL DESIGN CRITERIA Crusher type Cone crusher, hydraulically adjusted Application Minerals processing Crushing stage Secondary, tertiary, quaternary Max feed size 211 mm CSS range 541 mm Nominal capacity* 61283 mtph Ambient temperature 20°C to +40°C (Contact Sandvik if outside range) Altitude of site ≤ 2,000 mSANDVIK CH830i CONNECTED CONE CRUSHER

Superior P400 Patriot® Cone Crusher New Crushers

Manufacturer: Inventory #: Features: Standard Features Weight Approx 52,000 lbs, bare cone Main Frame One piece cast steel main frame assembly, AR steel liners, 4340 forged steel shaft, bronze seat liners with retention lip, bronze pin bushings, and cast arm guardsJun 24, 2015 MPS has announced the launch of the new TC1150 cone, which is designed around the high performance TC1000 TC1300 cones, with several improvements to enhance performance and functionality The first improvement is related to the upper frame and concave retention The TC1150 has a newly designed upper frame accommodating all available concave liners TC1150 Cone Crusher Features Newly Designed Upper Sep 18, 2019 Also referred to as “ring bounce” or upper frame movement, bowl float occurs when crushing action exceeds the design specifications of the cone While most crushers are engineered to open up due to tramp metal or an uncrushable – no cone crusher is designed to operate safely with bowl float or ring bounce – and when undetected, it will Crushing It: Improving cone crusher performance through The highly mobile plant combines a modern TC1150 300 HP Cone crusher with the highly efficient LJTSV 6x20 3 deck screen include automated cone controls and larger closed side settings and is rubber isolation mounted on a heavy duty chassis frame The new design also features more steel in the “rock zone” for industry leading Cedarapids CRC1150S Portable Cone and Screen PlantAug 01, 2019 The welding frame structure is firm and reliable without casting defects Unique flywheel design effectively reduces vibration, making machine operation more stable the fine crushing jaw crusher or the cone crusher is used as the secondary crushing to crush the material to less than 2 cm, and the selected granularity can be basically 2 Types of Concrete Crushers

Different types of crushing equipments Constro Facilitator

The rugged design, which incorporates a fabricated steel base frame lined with replaceable abrasionresistant steel liners, stands up to the toughest mineral processing applications while providing safe and simple operation, including an automatic tramp relief system to allow uncrushable objects to pass while the crusher remains in operationThe K200+ is a 200horsepower cone crusher and one of four models in the Kodiak Plus family of products The K200+ features a precision roller bearing design, as well as a new hybrid cast/fabricated base frame design, the ‘MILO’ automated control system, a new patented liner retention system, patented thread locking ring and antispin cone In Good Faith KPIJCI and Astec Mobile ScreensSandvik UJ210 offers a primary crushing solution fully assembled on a single trailer frame and mounted on a double axle bogie We have equipped this unit with the reliable and highly productive Sandvik CJ409 jaw crusher, to ensure the efficiency and productivity is outstanding It also comes equipped with features to enhance your productivity including feeder motors, starters, and a user UJ210 Wheeled unit — Sandvik Mining and Rock TechnologyApr 11, 2019 Cedarapids 32 in x 42 in jaw crusher 36 in discharge conveyor Three axle chassis New 11R225 tires All electric plant 200 HP motor Please contact us for more information ViewCedarapids 32 in x 42 in jaw crusher 36 in discharge Base Cone Crusher only 10,000 22,040 22,000 48,500 Crusher assembled on Live Frame with Motor, Motor Pulley, Vee Belts and Drive Guard 12,000 26,460 26,000 57,320 Hydraulic Panel (System 2) 300 660 Oil Tank 350with Airblast Cooler 770 390 860 Power Variation The power required will vary with the feed and product size, capacity and rock Minerals Processing Systems TC SERIES CONE

Portable Plants CRC1150S Closed Circuit Cone Screen Plant

Cone Specifications Maximum Feed Size Extra Course Configuration 220mm 87” Medium Course Configuration 190mm 75” Fine Configuration 110mm 43” Approximate Component Weights Basic Dimensions Whole Crusher Dry Weight 14000 Kg 31,360 lbs Upper Frame Assembly 4861 Kg 10,717 lbs Cone Head Assembly 1770 Kg 3,902 lbs Eccentric Assembly 1511 Apr 20, 2019 This Pin was discovered by Brendon Whateley Discover (and save!) your own Pins on Pinterestjaw crusher animation Crusher, Jaw, Mechanical design