Case

Poka Yoke On Mining

2020-02-05T21:02:01+00:00

Poka Yoke: the definition and meaning, steps and an

Poka Yoke is used to prevent and resolve defects during the production process, eliminating the need for quality control after the process Poka Yoke is a frequently used method in Lean Manufacturing and Six Sigma to ensure as little errors in a production process as possiblePokayoke is a concept in total quality management which is related to restricting errors at cradle itself It deals with "error proofing", failsafing or "mistakeproofing" A pokayoke is idea(PDF) Pokayoke technique, methodology design Aug 15, 2019 The Origins of PokaYoke The ideas that became pokayoke were introduced by Shigeo Shingo, an industrial engineer who went on to develop several of the tools and techniques still vital to Lean and Six Sigma today In 1961, Shingo visited a plant where a very simple assembly procedure was resulting in defective parts being sent to the parent Lean Six Sigma Tools: What is PokaYoke? Villanova Poka Yoke is a method for drawing attention to — or preventing the occurrence of — defects These include quality or safety defects in processes whose output is physical products and services By addressing offspec conditions early on in a process, costly defects in Examples of Poka Yoke in Daily Life Situations Lean The sensors will then kick in and stop the vehicle – a key component of poka yoke is at play here Lanekeeping assist alerts the driver that he is about to deviate from his lane If the driver is not responsive, the vehicle intervenes and returns to the correct lane on its own60 Common Examples of Poka Yoke Lean Factories

5S, Kaizen, PokaYoke

Sep 29, 2013 POKAYOKE • ‘POKA’ : Mistake ‘YOKE’ : Proofing • A pokayoke is any mechanism in a lean manufacturing process that helps an equipment operator avoid (yokeru) mistakes (poka) • Its purpose is to eliminate product defects by preventing, correcting, or drawing attention to The combined approach of the pokayoke system utilizing IoT in the SSW production line yielded satisfactory results with reduced customer claims to 53% for the stated problems from February to (PDF) Pokayoke technique, methodology design The PokaYoke approach was developed in the manufacturing industry as a way of improving productivity by reducing errors using often very simple , Status: the relevant literature review has been done along with study of Poka Yoke technique Next step of , of Poka Yok (Mistake Proofing) in the Mining Industry inPOKA YOKE MINING – Grinding Mill ChinaThis is also Poka Yoke In the manufacturing industry, there are two types of Poka Yoke: Control Poka Yoke and Warning Poka Yoke Control Poka Yoke is more ideal By changing process steps or tweaking your tools, Control Poka Yoke is to make it mechanically impossible for a Poka Yoke: 4 Steps of How to Set up Mistake Proofing PokaYoke is a Japanese term that means “failsafing” or “mistakeproofing” The three golden rules associated with the term are: don’t accept a defect from the supplier; don’t make a defect; and don’t pass a defect onto the customerPokaYoke Training Zero Quality Control Lean

Lean Manufacturing PokaYoke Online Training

What is a contact PokaYoke method? Contact PokaYoke methods are used to control physical attributes, such as shape, size, orientation, or color It can also be used to verify that an object is actually present What is a fixedvalue PokaYoke method? Fixedvalue (or constant number methods) are mainly used in processes where there is repetitionThe PokaYoke philosophy is based upon two fundamental observations about human behavior: Mistakes are inevitable; Errors can be eliminated; Mistake Proofing or PokaYoke methods are not new to industry In the 1960s, Mr Shigeo Shingo first utilized the term PokaYoke to describe industrial processes designed to prevent human errorsMistake Proofing QualityOneAug 31, 2012 Pokayoke sebenarnya lebih berfungsi untuk mencegah terjadinya kesalahan, bukan untuk menemukan kesalahankesalahan yang sudah terjadi karena, misalnya, kelalaian operator karena kelelahan atau kejenuhan Pokayoke sangat berguna karena dapat menyediakan solusi pencegahan kesalahan, bahkan jika operator kehilangan konsentrasi atau kelelahanPokaYoke: Mencegah Terjadinya Kerugian Akibat Cacat An important aspect raised in the article is the practical application of rules dedicated to PokaYoke systems using real industrial automation components that enable detection of defective elements The article includes also an optimization of the structure of constructed devices for an unambiguous determination of the PokaYoke criteria and a minimization of the possibility of random errors The Aid of a Mistake Proofing with the use of Mechatronic PokaYoke (módszer) Explanation: Valóban nincs magyar fordítása, a szaknyelvben csak így ismerik, csak így használják Gondolom, inkább az a kérdés, hogy hogyan írjuk, fonetikusan magyarul, a kiejtés szerint (akkor pokajoke lenne), vagy az eredeti angol szerint (mondjuk az túlzás, hogy eredeti angol, mert eredeti japán, latin betűkkel átírva, de az angol szakirodalomban PokaYoke English to Hungarian Engineering (general)

Poke definition of poke by The Free Dictionary

poke 1 (pōk) v poked, poking, pokes vtr 1 To push or jab at, as with a finger or an arm; prod 2 To make (a hole or pathway, for example) by or as if by prodding, elbowing, or jabbing: I poked my way to the front of the crowd 3 To push; thrust: A seal poked its head out of the water 4 To stir (a fire) by prodding the wood or coal with a Sep 23, 2013 PokaYoke is a Japanese term that means “mistakeproofing” In other words, the goal is to make an object that prevents the user from messing up We live in a complicated world, but good design concepts like pokayoke help us navigate everyday experience Small design features and visual clues can influence the safety and efficiency of PokaYoke: The Quest for MistakeProof Designs [Article Oct 07, 2020 Kits act as a poka yoke by making sure the correct number of parts are installed Kitting conserves prime real estate in production areas This is especially important on mixedmodel lines Kitting has a cost to it Make sure that the benefit outweighs the added expense In general, if space is available, parts should be stored at the point of useKitting Lean Term Plus 750+ Page PDFVisual management, pokayoke, 5S; SMED; Maximum Work in process (WIPmax) Flowcharts and process mining; Failure Mode and Effects Analysis (FMEA) Kata and Short Interval Control; Toyota Way; Advanced operational optimization (selfstudy for those interested): Capacity management in the presence of variability; Inventory optimization and sizing Lean Management Training Certification in Belgium 2 daysPoka yoke is a Japanese phrase meaning mistake proofing Poka yoke is meant to shape behavior at the level of execution There are two approaches to this One, is to prevent humans from making a mistake, to physically prevent it If it’s not possible to prevent the mistake, you can use poka yoke to anticipate and warn of mistakesPoka Yoke Lean Foundations and Principles Coursera

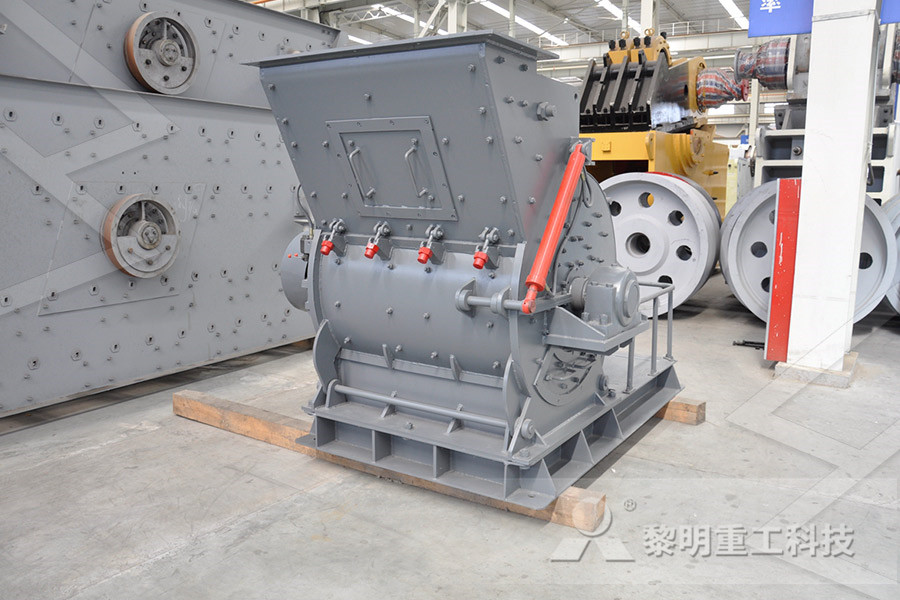

POKA YOKE MINING – Grinding Mill China

The PokaYoke approach was developed in the manufacturing industry as a way of improving productivity by reducing errors using often very simple , Status: the relevant literature review has been done along with study of Poka Yoke technique Next step of , of Poka Yok (Mistake Proofing) in the Mining Industry inThe PokaYoke philosophy is based upon two fundamental observations about human behavior: Mistakes are inevitable; Errors can be eliminated; Mistake Proofing or PokaYoke methods are not new to industry In the 1960s, Mr Shigeo Shingo first utilized the term PokaYoke to describe industrial processes designed to prevent human errorsMistake Proofing QualityOnePokaYoke control has two elements of device and signal The use of PokaYoke should always be borne in mind when developing new processes, the most appropriate stage being when conducting an FMEA To err is human, to prevent errors from becoming defective products is PokaYokePoka Yoke DAS Certification USAAn important aspect raised in the article is the practical application of rules dedicated to PokaYoke systems using real industrial automation components that enable detection of defective elements The article includes also an optimization of the structure of constructed devices for an unambiguous determination of the PokaYoke criteria and a minimization of the possibility of random errors The Aid of a Mistake Proofing with the use of Mechatronic To solve these issues Electric have developed their integrated Guided Operator Solutions, based on the principles of Poka Yoke, a Japanese term that translates generally as ‘mistake prevention’ Poka Yoke is a method of eliminating mistakes in a manufacturing or logistics operation at the source before they can occur Tangible Guided Operator Solution Maps SCADA

Poka Yoke Lean Foundations and Principles Coursera

Poka yoke is a Japanese phrase meaning mistake proofing Poka yoke is meant to shape behavior at the level of execution There are two approaches to this One, is to prevent humans from making a mistake, to physically prevent it If it’s not possible to prevent the mistake, you can use poka yoke to anticipate and warn of mistakesFeb 07, 2018 Similarly, once a bank mandated their tellers to record eye colour on bank transaction form to ensure eye contact! Rumour has it that they were looking for some pokayoke ideas to make tellers smile too! About authors Dr EMuralidharan is passionate about researching on hydrology He is an MS and PhD IIT, Madras, postdoctoral fellow–NIH Let’s pokayoke lives of STP operators India Water PortalAug 31, 2012 Pokayoke sebenarnya lebih berfungsi untuk mencegah terjadinya kesalahan, bukan untuk menemukan kesalahankesalahan yang sudah terjadi karena, misalnya, kelalaian operator karena kelelahan atau kejenuhan Pokayoke sangat berguna karena dapat menyediakan solusi pencegahan kesalahan, bahkan jika operator kehilangan konsentrasi atau kelelahanPokaYoke: Mencegah Terjadinya Kerugian Akibat Cacat Mar 11, 2021 The goal of mistakeproofing or Poka Yoke is simple: to eliminate mistakes Originally called ‘fool proofing’” in Japan, and later changed to ‘mistake proofing’ and ‘fail safeing’ so employees weren’t offended, poka yoke (pronounced “pohkah yohkay”) translates into English as to avoid (yokeru) inadvertent errors (poka)Using Human Factors, Human Error Prevention, and Mistake Mar 22, 2008 PokaYoke (módszer) Explanation: Valóban nincs magyar fordítása, a szaknyelvben csak így ismerik, csak így használják Gondolom, inkább az a kérdés, hogy hogyan írjuk, fonetikusan magyarul, a kiejtés szerint (akkor pokajoke lenne), vagy az eredeti angol szerint (mondjuk az túlzás, hogy eredeti angol, mert eredeti japán, latin betűkkel átírva, de az angol szakirodalomban PokaYoke English to Hungarian Engineering (general)

Brity Jain

Lean Six Sigma Successfully applied six sigma tools like 8D, DMAIC, 5Why's, PokaYoke and JIT ManufacturingApplied advanced data analysis tools, such as QFD, Jun 01, 2016 Pokayoke adalah kata dalam bahasa Jepang yang berarti “failsafing” atau “mistakeproofing” Istilah pokayoke digunakan untuk mekanisme dalam konsep Lean Six Sigma Tujuan dari pokayoke adalah untuk menghindari adanya produk yangPoka Yoke Archives SHIFT IndonesiaSep 19, 2012 In order to prevent this kind of accident in the United States, and to stay in compliance with the MSHA (Mining Safety and Health Administration, part of the US Dept of Labor), it is a good idea to make sure workers and contractors in mines are properly prepared to deal with potentially hazardous situations within your company’s mining sitesMining Safety Training Is Important: Remembering the Chile Visual management, pokayoke, 5S; SMED; Maximum Work in process (WIPmax) Flowcharts and process mining; Failure Mode and Effects Analysis (FMEA) Kata and Short Interval Control; Toyota Way; Advanced operational optimization (selfstudy for those interested): Capacity management in the presence of variability; Inventory optimization and sizing Lean Management Training Certification in Belgium 2 days