Case

tor aggregate crusher stone pdf

2020-03-21T07:03:02+00:00

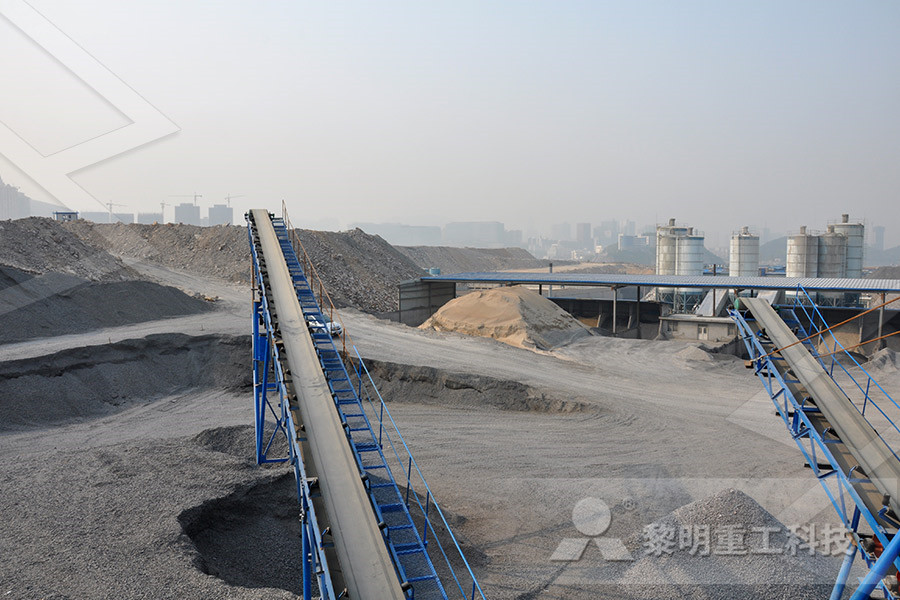

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB

A crushed stone plant differs somewhat from a sand and gravel plant Raw material is brought f rom a quarry to a prim ary crusher by rear dum p haul tru cks Som e prim ary crush ers are fed by wobblers, which are chain driven conveying systems with eccentric rollersstorage pile and sold as base material The stone that is too large to pass through the top deck of the scalping screen is processed in the secondary crusher Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 25 to 10 centimeters (1 to 4 inches)AP42 Section 11192 Crushed Stone Processing and Rock, crushed stone and sand and gravel are natural aggregate products used for a variety of applications including road and utility construction, backfill, erosion control and slope protection If you are running an aggregate processing facility, you should be aware of March 2017 Running a Crushed Stone or Sand and Gravel Pit gravel meeting the requirements of Subsection 90305, for Type B, Grading D The aggregate may be a "crusher or pit run" or may be sized into 2 or more sizes If the material is "crusher or pit run", care shall be taken to prevent segregation during stockpiling and handling 90305Aggregate for Mineral Aggregate Base and Surface CoursesPART 9MATERIALS TNgovIn the crusher machine after crushing of stone the product retained known as crushed stone dust If can be used as a fine aggregate in cement concrete as a replacement of sand it may be replace fully or partially as a percentage of 20%, 40%, 50%, 60%, 80% of gives the higher strength as that of sand gives with the help of suitable admixtures(PDF) The Utilization Of Crushed Stone Dust As A

Crushed Stone Description and Uses (Pennsylvania locations)

CR6 (Crusher Run)DELDOT MDDOT Approved x fines 11/2" Driveway parking lot base, compactable Dimension Stone x Building construction Driving Surface Aggregate (DSA) x fines 11/2" Dirt and gravel roads, designed to hold together with minimal maintenance Fill x dirt Subsoil dirt, overburden, mixture of dirt and rock Fine Base x xRock, crushed stone and sand and gravel are natural aggregate products used for a variety of applications including road and utility construction, backfill, erosion control and slope protection If you are running an aggregate processing facility, you should be aware of March 2017 Running a Crushed Stone or Sand and Gravel Pit Stone Processing activities include conveying, screening, secondary and tertiary crushing, and sizing Screening is the single most important part of the processing cycle of crushed stone particles A wide variety of screen types exist, and their selection is a function of the material processed and the final product requiredLimestone and Crushed Rock EnergygovIn the crusher machine after crushing of stone the product retained known as crushed stone dust If can be used as a fine aggregate in cement concrete as a replacement of sand it may be replace fully or partially as a percentage of 20%, 40%, 50%, 60%, 80% of gives the higher strength as that of sand gives with the help of suitable admixtures(PDF) The Utilization Of Crushed Stone Dust As A aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone Crushing, screening, and washing may be used to process aggregates from either sand and gravel deposits or stone quarries Aggregates may be produced from igneous, sedimentary, or metamorphic rocks, but geological type does not by itself make an aggregateAggregates for Concrete

PART 9MATERIALS TNgov

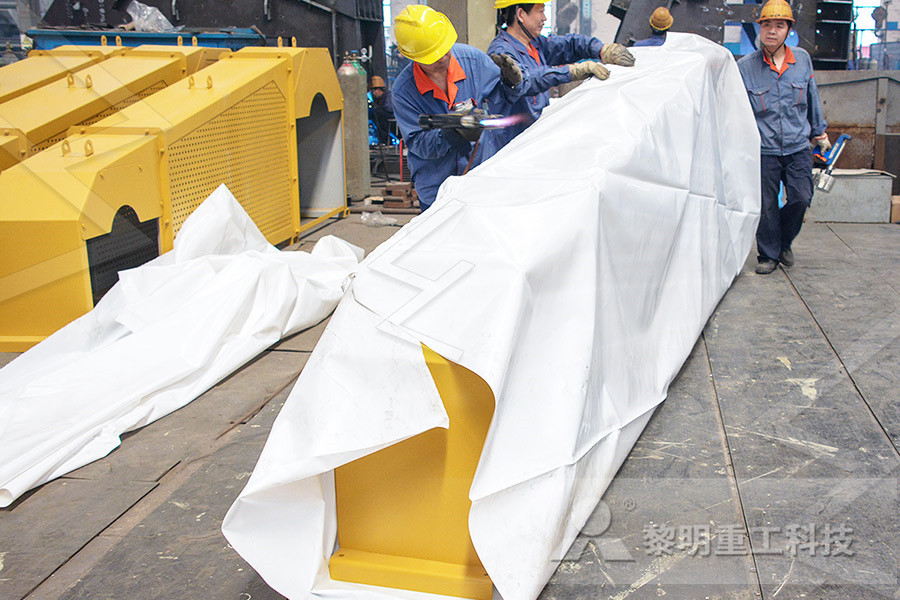

gravel meeting the requirements of Subsection 90305, for Type B, Grading D The aggregate may be a "crusher or pit run" or may be sized into 2 or more sizes If the material is "crusher or pit run", care shall be taken to prevent segregation during stockpiling and handling 90305Aggregate for Mineral Aggregate Base and Surface CoursesThis kind of impact stone crusher is a kind of hig hefficient strong coarse and mid crushing equipment we company produced And the an tipressure is less than 150Mpa and it can rep lace the(PDF) SIZE REDUCTION BY CRUSHING METHODSThe design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous useDesign and Construction of Rock Crushing Machine from basalt or crushed limestone, aggregate sizes of 12 mm ('h in) or 19 mm (:Y in), and coarse aggregate contents with aggregate volume factors (ACI 211191) of075 and 067 Watertocementitious material ratios range from 024 to 050 Compressive strengths range from 25 EFFECTS OF AGGREGATE TYPE, SIZE, AND CONTENT ON Quarrying Process Quarry Products Page 2 of 8 After the face profiling survey, the drilling contractor arrives Using an air operated drilling rig, he drills the number of shot holes required, at the marked spots corresponding to the hole positions on the blast design, at the angles and depths required After the shot holes have been drilled, they are surveyed toQUARRYING PROCESS AND QUARRY PRODUCTS

Specifications For CRUSHED AGGREGATE BASE COARSE #2

crushed gravel or crushed stone, fine aggregate and binder or filler blended as necessary to produce an intimate mixture of the required gradation and stability Requirements: The aggregate shall consist of hard, durable particles of crushed stone or crushed gravel and a filler of natural sand, stone sand or other finely divided mineral matterstorage pile and sold as base material The stone that is too large to pass through the top deck of the scalping screen is processed in the secondary crusher Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 25 to 10 centimeters (1 to 4 inches)AP42 Section 11192 Crushed Stone Processing and SAND, GRAVEL, AND CRUSHED STONE INDUSTRY and to transport unfinished material from the quarry to the crusher, or from the pit to the prim ary dum p st ation Larg e haulag e trucks m ay cause serious accidents and injuries on the xc should be present to moni tor the training OJT is conducted at the actual job site, where theSAND, GRAVEL, AND CRUSHED STONE ONTHEJOB were the most common choice crushers, but in recent years impact crushers are more widely used These crushers also are sometimes used as primary crushers for finegrained gravel deposits The cone crusher (a compression type) simply crushes the aggregate between the oscillating cone and the crusher wa ll (Figure 59) Clearance settings on5 Aggregate Production INgovCR6 (Crusher Run)DELDOT MDDOT Approved x fines 11/2" Driveway parking lot base, compactable Dimension Stone x Building construction Driving Surface Aggregate (DSA) x fines 11/2" Dirt and gravel roads, designed to hold together with minimal maintenance Fill x dirt Subsoil dirt, overburden, mixture of dirt and rock Fine Base x xCrushed Stone Description and Uses (Pennsylvania locations)

Design Guide 6 USDA

Materials, Section 9010201 Stone for Riprap and is shown on the following pages In addition, other gradations of aggregate are contained in American Association of State Highway and Transportation Officials (AASHTO), Standard Specifications for Crusher run Aggregate CR6 D 2940 (h) 6 12 15 50 Bank Run Gravel – Subbase D were the most common choice crushers, but in recent years impact crushers are more widely used These crushers also are sometimes used as primary crushers for finegrained gravel deposits The cone crusher (a compression type) simply crushes the aggregate between the oscillating cone and the crusher wa ll (Figure 59) Clearance settings on5 Aggregate Production INgovstone, aggregate resources, and raw materials for cement and other industrial and agricultural uses Over 70 percent of crushed stone produced in the United States is made from carbonate rock The products derived from carbonate rocks provide essential materials for society – materials that we need to maintain our current standard of livingPotential Environmental Impacts of Quarrying Stone in aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone Crushing, screening, and washing may be used to process aggregates from either sand and gravel deposits or stone quarries Aggregates may be produced from igneous, sedimentary, or metamorphic rocks, but geological type does not by itself make an aggregateAggregates for ConcreteThe design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous useDesign and Construction of Rock Crushing Machine from

Lecture 4 Aggregates Aalto

• Recycled aggregate is derived from crushing inert construction and demolition waste It may be classified as recycled concrete aggregate (RCA) when consisting primarily of crushed concrete or more general recycled aggregate (RA) when it contains substantial Siliceous Gravel or Crushed Stone 0 035 3070 75100 95100 SCA3 Siliceous Gravel or Crushed Stone 0 020 4070 95100 SCA4* Siliceous Gravel, Chat or Crushed Stone 0 020 95100 SCA5 Crushed Siliceous Gravel, Chat and Crushed Stone 0 010 1550 85100 *Use with Basic Aggregate to produce Mixed Aggregate1102 AGGREGATES FOR CONCRETE SECTION 1102 Crushers Crushers are key process components in several industries dealing with materials such as minerals, chemicals or agro based products Whatever the material to be processed, productivity is of the essence and monitoring the material level is mandatory to optimize crushers operation Measurement made easy OptimizationLaser and ultrasonic level products CrushersBID 202105 AGGREGATE MATERIALS EFFECTIVE DATE: 02012021 THOURGH 01312022 VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR VENDOR Lattimore Materials Corp Green Dream International Mobile Crushing, Inc Dolese JR Thompson Tricounty Materials Cooke County Crushed Stone North Texas Crushed Stone P K Stone BID 202105 AGGREGATE MATERIALS EFFECTIVE DATE: 0201 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Aggregate Crushing Value Test YouTube

Standard Classification for Sizes of Aggregate for Road

11 This classification defines aggregate size number designations and standard size ranges for mechanical sieve analyses of coarse aggregate and screenings for use in the construction and maintenance of various types of highways and bridges 12 Units—The values stated in SI units are to be regarded as standardSmall Crushed Stone Small crushed aggregate is the type of stone that you most frequently get to see, as it is often used as the surface layer for an array of construction and landscaping projects These projects can include gravel driveways, patios, water features, tree circles, planters, parking lots, park playgrounds, etcCrushed Stone Guide: Find the Right Size for Your Next ProjectJaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate JXSC