Case

of a crushing crusher

2023-05-13T21:05:49+00:00

Crushing Principles of Mechanical Crushing

Crusher Operation • Relation between Feed size and Shape – The greater reduction ratio the worse particle shape – Inter particle breakage improves shape When crushing a bed of material weaker particles will break first Flaky or elongated particles are weaker then round – Breaking round particles gives flaky material F l a k i n e s s i n d e x [%]A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging openingCrushers an overview ScienceDirect Topics Mobile Crusher Plant Usually mounted on a tyre or crawler frame and selfpowered or moved using a tractor, mobile crushing plants are often used for onsite operations due to their great flexibility to be moved whenever requiredMobile Crusher Plant, Mobile Crushing Plant GEP

2 Types of Concrete Crushers

Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa Closed Circuit A crushing process arrangement in which part of the material produced by the crusher is circulated back to the same crusher for further crushing Comminution Generic name referring to any minerals processing operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces orMODELLING, SIMULATION AND OPTIMISATION OF A The feed comes from the primary crusher and will have a certain amount of rock that doesn’t need further crushing To run this ore through the crusher will be a waste of energy and crushing space Ideally it should be removed To remove it requires a Secondary Tertiary Crushing Circuits 911

Forces in a Cone Crusher SpringerLink

In research on the design and performance of cone crushers, it is generally assumed that crushing occurs as a result of the compression of the piece by mobile and immobile cones The motion of the material falling into the crushing chamber is described by three mechanisms: free fall, slip, and compression [ 16 ]A jaw crusher for crushing mineral material comprising a pitman which comprises an upper art comprising an upper supporting point for supporting the pitman in the body of the jaw crusher, and whichUSA1 Pitman of a jaw crusher, jaw Eagle Crusher Launches New Company site Eagle Crusher is pleased to announce the launch of our new company website that is designed to better help users find the right crushing and screening products for their operations An industry leader for more than 100 years,Maintaining the Hopper Feeder and Grizzly Eagle

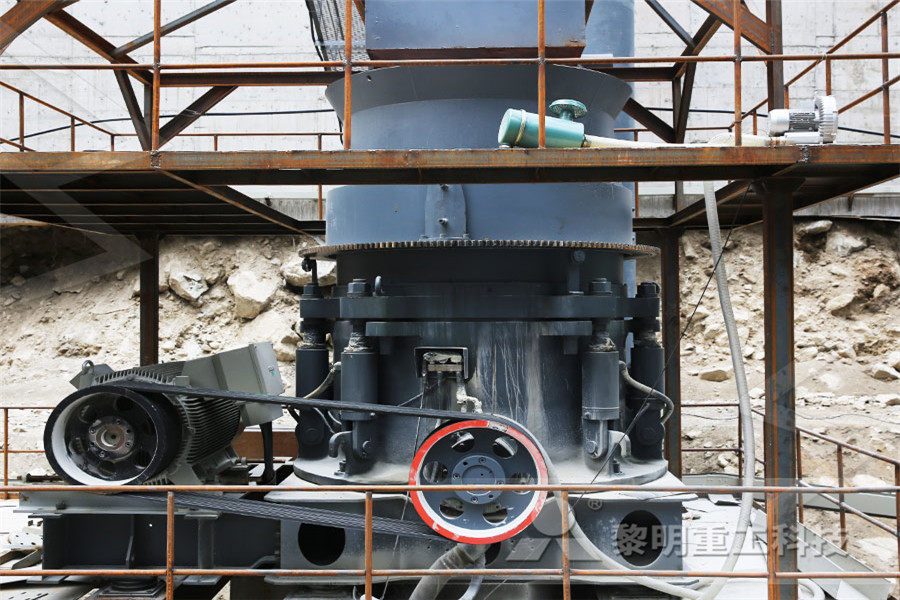

The pros and cons of cone crusher applications Quarry

A cone crusher in a secondary crushing application will typically work with a 35:1 to 5:1 reduction ratio Tertiary cone crusher configurations typically work with a reduction ratio of 25:1 to 4:1 The reduction ratio is defined as the ratio of the feed Understanding the crushing stages and the type of crusher best suited for each stage can simplify equipment selection Each type of crusher is different and is used to achieve a specific end result Similarly, it is expected that at the end of each crushing stage a certain throughput will be available for the next stage of the processUnderstanding the Crushing Stages of a CrusherCrusher machines are used for crushing of a wide variety of materials in the mining, iron and steel, and quarry industries In quarry industry, they are used for crushing of rocks into granites for roadbuilding and civil works Crusher machines are equipped with a pair of crusher Crushers an overview ScienceDirect Topics

The maximum crushing capacity of a wood particle

One of the factors determining the maximum crushing capacity is the motor output (kW) Even when a crusher has a large internal volume and is equipped with many crushing hammers of high rotation speed, ifit is driven with a motor of 120 extremely small output, the maximum crushing capacity willberestricted by that motor power the crusher, usually the result of wet and sticky material clogging exit points Circulating Load — The amount of oversize returned to the crusher from a screen in a closedcircuit system ClosedCircuit Crushing — A system in which oversize material is screened from the output and returned for another pass through the crusher D 50Handbook of Crushing TerraSourceTERTIARY IMPACT CRUSHER Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications Tertiary Impact Crushers MEKA Crushing

2 Types of Concrete Crushers

Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top sizeConstruction, Working and Maintenance of Crushers for A mechanical crusher machine is used for crushing aluminium cans and punched sheet metal wastes for recycling purpose and also for easy storage and transportation The crank and slotted lever mechanism converts the rotating motion into reciprocating motion, this is the principle which is used in the mechanical DESIGN OF MECHANICAL CRUSHING MACHINE

OPTIMIZATION OF COMPRESSIVE CRUSHING

ores, a truly optimal performance of a crushing application must be based on an optimized crusher design as well as a continuously optimized crusher operation Key words: compressive crushing, modeling, optimization, cone crusher, implementation Closed Circuit Crushing The feed comes from the primary crusher and will have a certain amount of rock that doesn’t need further crushing To run this ore through the crusher will be a waste of energy and crushing space Ideally it should be Secondary Tertiary Crushing Circuits 911 Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements Our cone crusher offering consists of four different product families that utilize the same crushing Cone crushers for demanding crushing needs

2 Types of Concrete Crushers

Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 MpaTERTIARY IMPACT CRUSHER Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications Tertiary Impact Crushers MEKA Crushing For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top sizeConstruction, Working and Maintenance of Crushers for

How To Choose a Crusher

PF Series Impact Crusher is used in crushing crispy, mediumhard materials such as limestone, coal, gangue, coke, etc It is used for secondary crushing and fine crushing Advantages of PF Series Impact Crusher 1Large capacity, big crushing ratio, angular shape aggregate, little A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral(s) from the Jaw Crusher Explained saVRee The crushing of minerals and ore is of great industrial importance With global population growth, urbanization, and continuing improvements in living conditions, the productivity and efficiency of existing crushers must be increased to meet the growing demand []Cone crushers are characterized by a continuous operating cycle and may process strong and abrasive materials such as granite, blast Forces in a Cone Crusher SpringerLink

What is a Jaw Crusher Advantages, Types, Parts and

Jaw crusher Advantages Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved Modular design is adopted to save time and Define crusher crusher synonyms, crusher pronunciation, crusher translation, English dictionary definition of crusher v crushed , crushing , crushes v tr 1 The act of crushing or the pressure involved in crushing: matter superheated by the crush of gravity around black holes 2 A great crowd: Crusher definition of crusher by The Free Dictionary Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone crusher Crushing Plant Flowsheet DesignLayout