Case

st analysis for mining equipment

2020-12-06T09:12:46+00:00

Equipment Cost Calculator Costmine

The Equipment Cost Calculator provides all the same information as our Mine Mill Equipment Cost Guide in a convenient online format Build your equipment fleet, tabulate its costs, adjust for local economics and conditions, and export the data Mining Cost Service continues to be a useful reference on a wide range of topics for early stage mine planning through to ‘fill the gaps’ on more detailed studies Mining Cost Service provides an independent source for information on equipment, quantities and cost for a significant number of mining Costmine Industry Standard for Mining Cost EstimatingIncluded are capital and operating costs for over 3,000 equipment items most commonly found at mines and mills around the world – from 2 HP pumps to 2,000 HP trucks, from $200 slusher buckets to $30,000,000 walking draglinesMine Mill Equipment Cost Guide CostmineIn our total cost of ownership studies, we examine all the expenses related to running your equipment, including replacement part costs, maintenance costs, and operational costs such as electricity, labor, and consumable parts These total expenses are divided by your production rates to determine your current cost per tonCostPerTon Programs Life Cycle Komatsu Mining CorpMining Cost Service is the industry standard reference for Mining Cost Estimation This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible Monthly updates assure that Mining Cost Service Costmine

BREAKEVEN ANALYSIS OF MINING PROJECT

BREAKEVEN ANALYSIS OF MINING PROJECT 23 Surface vs underground mining costs 5 231 Mining method costs 6 24 Budgeting and cost control 8 25 Capital budgeting: methods of appraisal 11 521151 Mining equipment 40 52116 Production plan for surda mines 41Based on an analysis performed in a case study, a life cycle cost (LCC) optimization model has been developed, taking the most important factors affecting the economic replacement time of drilling(PDF) Reliability and Life Cycle Cost Modelling of Mining Apr 04, 2020 This is the value of cryptocurrency that must be produced for the cost of the rig to be paid for For example, one featured Bitcoin mining rig costs USD $1,767 to build and operate and generates $456 in profit per day at current prices Thus, it would need to run for 387 days to become profitable Factored into this number are electricity costsWhat Would it Cost to Build a Bitcoin Mining Rig Today Equipment lifecycle cost analysis (LCCA) is typically used as one component of the equipment fleet management process and allows the fleet manager to make equipment repair, replacement, and retention decisions on the basis of a given piece of equipment’s economic life The objective of this research is to develop a robust method thatMajor Equipment Lifecycle Cost Analysisthe selection of mining equipment These models are life cycle cost analysis3, net present value analysis4, linear breakeven model5, linear programming6 and decision making tools such as reliability analysis, knowledge based expert systems and analytical hierarchy processes7–9 The most important factors for the selection of opencast mining Equipment selection for high selective T excavation

Fundamentals of Cost Part 1: The Time Usage Model

Feb 25, 2016 Fundamentals of Cost Part 1: The Time Usage Model Published on February 25, 2016 February 25, 2016 • 166 Likes • 28 CommentsCritical to all mining operations is the “break even” factor, which the mining estimator seeks to determine This is the value of cryptocurrency that must be produced for the cost of the rig to be paid for For example, one featured Bitcoin mining rig costs USD $1,767 to build and operate and generates $456 in profit per day at current pricesWhat Would it Cost to Build a Bitcoin Mining Rig Today The distribution of problems affecting a fleet of equipment ranked in terms of MTBS, MTTR, impact on Availability and Costs All mining companies have limited resources; the most successful operations use a Pareto analysis to identify top problems to obtain a clear understanding of the key issues they face, and establish priorities in order to Influencing Mining Equipment Performance Through This paper provides a critical analysis of the various models for surface mining operations, identifying important constraints and suitable objectives for an equipment selection model A new Mixed Integer Linear Programming model is presented that makes use of a linear approximation of the cost function This model allows for mixedModels for Mining Equipment SelectionThe capital expenditures (CAPEX) of a mining operation are any costs that are incurred over a onetime purchase, and encompass any alreadyproduced assets such as equipment and infrastructure Capital cost estimates for mobile equipment are typically provided by the manufacturers, who supply suggested list prices for pieces of mobile equipmentEquipment selection QueensMineDesignWiki

cost benefit analysis mining equipment

cost benefit analysis mining equipment 6 benefits of using predictive maintenance following are different cost benefits of using predictive maintenance cost benefits of vibration analysis reduces equipment costs of replacement of the entire piece of equipment due to critical failure, a repair is made prior to failure and cost is minimized to the price of the component and the labor needed in the area maintenance of the equipment used in mines is the area of concern and the management also did not give it much importance Some study also reveals that the maintenance cost of the opencast mining equipment varies from 3050% of the total operational cost in mechanized minePERFORMANCE ANALYSIS OF HEAVY EARTH MOVING Stoping cost is one of the largest of the items comprising the total cost of producing ore The cost per ton of ore mined is important but may be overemphasized if the more important cost, that per unit of metal recovered, is thereby overlooked A given stoping method may give a low cost per ton of ore but, by reason of high dilution involving the handling, hauling, hoisting, and treating of a Cost of Stoping for Underground MiningFailure to keep your equipment in check or the continuous usage of a piece of mining equipment that is already malfunctioning will only make the problem worse According to experts, a typical cost of downtime in mining companies can average at about $180,000 This is the cost per incidentCost of Downtime When Machinery Breaks Down in the Mining reliability analysis of mining equipment such as loadhauldump (LHD) machines [1, 16, 17] In these studies, graphical and analytical techniques have been used to fit probability distributions for the characterization of failure data, and reliability assessments of repairable mining machines have been reported in these papersReliability Analysis and Failure Prediction of

Underground mining equipmentMarket by Services, Technology

Feb 08, 2021 Underground Mining Equipment Market is valued at USD 13442 Billion in 2018 and expected to reach USD 25035 Billion by 2025 with the CAGR of 929% over the forecast period– increasing mining activities for extraction of metals and minerals is the key driving factor of Global Underground Mining Equipment Market Underground mining equipment market report published Cost Benefit Analysis of the Mining Sector in Karamoja, Uganda Houdet J, Muloopa H, Ochieng C, Kutegeka S and Nakangu BCost Benefit Analysis of the Mining Sector in Karamoja, Equipment plays an important role in open pit mining industry and its cost competence at efficient operation and maintenance techniques centered on reliability can lead to significant cost reduction(PDF) Application of reliabilitycentered maintenance for (1997) Surface mining equipment cost analysis with a developed linear break even model International Journal of Surface Mining, Reclamation and Environment: Vol 11, No 2, pp 5358Surface mining equipment cost analysis with a developed (1997) Surface mining equipment cost analysis with a developed linear break even model International Journal of Surface Mining, Reclamation and Environment: Vol 11, No 2, pp 5358Surface mining equipment cost analysis with a developed

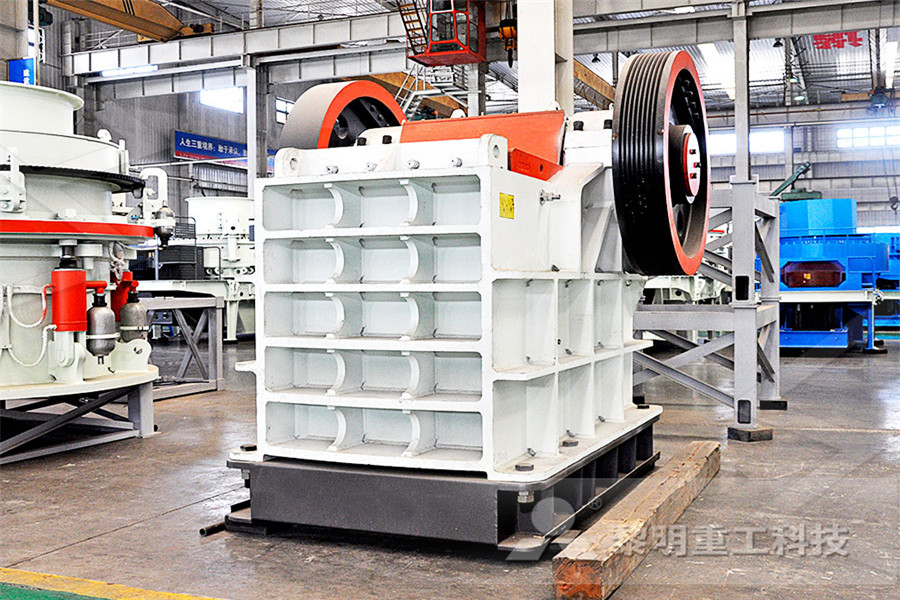

Mining Equipment Market Share, Statistics Industry

Industry Trends Mining Equipment Market size was valued at over USD 70 billion in 2017 which is expected to grow at over 5% CAGR from 2018 to 2024The global shipments are expected to surpass 450 thousand units by 2024 Some of the most used mining equipment are mining drills, blasting tools, crushers, conveyers, online elemental equipment and feeders The usage of these equipment Cost Benefit Analysis of the Mining Sector in Karamoja, Uganda Houdet J, Muloopa H, Ochieng C, Kutegeka S and Nakangu BCost Benefit Analysis of the Mining Sector in Karamoja, in the area maintenance of the equipment used in mines is the area of concern and the management also did not give it much importance Some study also reveals that the maintenance cost of the opencast mining equipment varies from 3050% of the total operational cost in mechanized minePERFORMANCE ANALYSIS OF HEAVY EARTH MOVING The capital expenditures (CAPEX) of a mining operation are any costs that are incurred over a onetime purchase, and encompass any alreadyproduced assets such as equipment and infrastructure Capital cost estimates for mobile equipment are typically provided by the manufacturers, who supply suggested list prices for pieces of mobile equipmentEquipment selection QueensMineDesignWikiApr 01, 2008 Effectiveness of the mining equipment is mainly influenced by the availability, reliability and maintainability of the system, and its capability to perform as expected Reliability analysis techniques have been gradually accepted as standard tools for the planning and operation of automatic and complex mining systems since the mid1980sReliability analysis of mining equipment: A case study of

(PDF) Determining Economic Life of Earth Moving Equipment

The Figure 2 shows the different cash flows when replacing equipment on a 1, 2, and 3year cycle where A=Acquisition cost C 1 =Operations and maintenance (OM) cost of a equipment in its first year of life C i =OM cost of a equipment in its ith year of life, assuming payable at the start of the year, i=1,2, 3, , n r=Discount factor S developed the Mining Equipment Productivity Index (MEPI), which provides a more precise estimate of the productivity of mining operations by measuring the physical output of the mine equipment Our operationallevel analysis has revealed that: • The global mining industry’s open cut equipment productivity has declined by around 20% over theHow a focus on equipment performance productivity returns reliability analysis of mining equipment such as loadhauldump (LHD) machines [1, 16, 17] In these studies, graphical and analytical techniques have been used to fit probability distributions for the characterization of failure data, and reliability assessments of repairable mining machines have been reported in these papersReliability Analysis and Failure Prediction of A cost analysis focuses on the cost of any given decision, project, or action without considering what the total outcome will be This type of analysis is the first step you would take before doing the other 3 economic evaluations to see if it is feasible or suitable for the company8+ Cost Analysis Templates Examples (Word Excel PDF)The global mining equipment market was worth $722 billion as of 2016 reports, and it is expected to grow at a CAGR of 7–8 percent until 2021 The APAC region has been holding the largest market share for the global mining equipment demand since 2015, and it will continue to dominate the market demand in the forecast period How is the mining Maintenance Services Market Research Price, Forecast

Operating Cost for Miners SRK Consulting

Aside from assessing and evaluating socialenvironmental concerns and designing the mining and material movement approach, the first question often asked is, "how much will it cost us to mine?" This may need to be determined even before you decide that there is a potential project Mine cost estimation may be done at many levelsMar 18, 2021 Concluding its threepart series focussing on mining transport, FERRIT takes a closer look at how the proper handling of mining material ensures maximum efficiency, safety and security during transport, while contributing to a noticeable reduction in operational costsCost benefits of handling mining material properly during Use the powersizing model to estimate the cost of a piece of equipment that has 75% more capacity than a similar piece of equipment that cost $1,000 The appropriate power sizing exponent for this type of equipment is 0725 Choose an answer by clicking on one of the letters below, or click on "Review topic" if needed A $1,750 B $725 C $750 Cost Estimating and Estimating Models