Case

oling on grinding machine using liquiding nitrogen

2021-10-10T02:10:13+00:00

Cryogenic Grinder (Liquid Nitrogen Cooling) YouTube

Jan 15, 2016 Zhangjiagang Techno Machinery Co,Ltd technomachinery: extrusion@technomachinery MsCrystalThis is a multipurpose grinder,using LLiquid Nitrogen Cooling with July/August 2016 processcooling 19 CHILLERS By Bonnie Martens, Dimplex Thermal Solutions M any industrial processes utilize a process fluid to cool the equipment by moving heat away from the operation An industrial chillerVol 4, No 6 Cooling with Liquid Nitrogen(4,5) Nguyen and coworkers studied the microstructure, hardness, and residual stress development of a grindhardened layer using cooling media, such as dry air and liquid nitrogen, (6) and (PDF) Grindinghardening with liquid nitrogen: Mechanisms Liquid nitrogen Cooling Plastic Pulverizer, also known as freezer milling, freezer grinding, and Freezing Pulverizer is the act of cooling or chilling a material and then reducing it into a small particle sizeChina Liquid Nitrogen Cooling Plastic Pulverizer,Freezing Grinding (Retsch Mixer Mill MM 400) 10 Fill several dewars and the cooling box (Retsch Cryo Kit #223540001) with liquid nitrogen 11 Label and then immerse two steel grinding jars (Retsch 50ml stainless steel jars #014620216) and grinding balls into liquid nitrogen until boiling stops 12 Remove jar with tongs and dump out excess liquid N2 13Yeast Lysis by Liquid Nitrogen Grinding

Cold Grinding messergroup

During mill cooling, liquid nitrogen or carbon dioxide is sprayed directly into the grinder which lowers the temperature By suppressing the heat generated during grinding, this cooling technique ensures stable performance of the process and increases the quality of the milled product A product cooler freezes materials rich in oil or fatDec 24, 2018 WANROOETECH is an Cryogenic Grinders Manufacturer for Cryogenic Grinding,Nitrogen Cooling Pulverizer,Cryogenic Grinder,Cryogenic Pulverizer,Nylon Pulverizer Cryogenic Grinding,Nitrogen Cooling Pulverizer,Cryogenic Liquid nitrogen (LIN) is used in innovative cooling and freezing technologies LIN is an effective and convenient refrigerant due to its availability, low cost, and inert properties It is also a practical cryogen for most lowtemperature applications because of its extremely low boiling temperature (–1958°C) and high refrigeration capacity Cool Down with Liquid Nitrogen AIChEMay 27, 2015 5ME’s exclusive liquid nitrogenbased cryogenic machining technology doesn’t require coolant fans, pumps, or mist collectors Our technology utilizes liquid nitrogen as a refrigerant, which evaporates into a nontoxic, nongreenhouse gas As a result, there’s no need for mist collection, filtration, or collection of waste coolantBenefits of Nitrogenbased Cryogenic Machining vs Jan 28, 2011 In this approach, liquid nitrogen flows through the spindle and through the tool at a low rate similar to that of minimum quantity lubrication, or MQL Unlike MQL, however, the purpose here is not lubrication The purpose instead is cooling The purpose is extreme coolingThe 400° Difference Modern Machine Shop

Grindinghardening with liquid nitrogen: Mechanisms and

liquid nitrogen whilst acts as a protective shielding, can also provide high cooling rates to promote metallurgical changes However, these advantages have not been explored in grinding This paper proposes an innovative development of grinding–hardening technology using liquid nitrogen to integrate precision surface grinding Jan 01, 2014 A hydraulic surface grinding machine was used to carry out the grinding tests under cryogenic cooling and oil based conventional cooling The surface grinder used in the experiment with liquid nitrogen Influence of cryogenic cooling on surface grinding of (4,5) Nguyen and coworkers studied the microstructure, hardness, and residual stress development of a grindhardened layer using cooling media, such as dry air and liquid nitrogen, (6) and (PDF) Grindinghardening with liquid nitrogen: Mechanisms Cryogenic technology for product cooling It is necessary to use liquid nitrogen in cryogenic grinding processes to produce very highquality powders The material to be milled is sent from the feed hopper through the dosing screw to the paddle screw cooler Liquid nitrogen Cold grinding and recycling Messer Groupthat liquid nitrogen has successfully acted as a protective shielding in grinding 33 Heating mechanism in the grinding zone All the above show that liquid nitrogen is a superior cooling medium A New GrindingHardening Technology Using an Inert Cryogen

How to use cooling in grinding process? PCD Tool Grinder

During grinding, the abrasive particles and chips are formed, and the lubricating effect of the abrasive particles and the machining surface is formed 6 Selfaccelerating method By using the principle of liquid dynamic pressure, the grinding fluid can get a speed equal to the wheel cycle speed, thus producing a synchronous cooling During mill cooling, liquid nitrogen or carbon dioxide is sprayed directly into the grinder which lowers the temperature By suppressing the heat generated during grinding, this cooling technique ensures Cold Grinding messergroupJan 28, 2011 Graphs at right quantify some of the performance benefits of liquid nitrogen cooling In titanium, a tool running at 300 sfm (aggressive for this material) wears out after 1 minute under flood The 400° Difference Modern Machine ShopAug 01, 2005 1 Introduction Abrasive processes, and grinding among them, are some of the oldest manufacturing methods known to man Yet grinding still accounts for about 25% of machining swarf in the industrialized world, and can produce high accuracy and excellent surface properties , New abrasive materials, new highperformance grinding machines and new manufacturing methods will allow grinding Mist jet cooling of grinding processes ScienceDirectThis grinding mill with liquid nitrogen adopts outer media freezing method to pulverize the materials to realize the heat exchange between material and liquid nitrogen, which can produce remarkably high fineness and is eminently suited to the size reduction of particularly difficult materials This machine can use China Low Temperature Cryogenic Grinding Mill

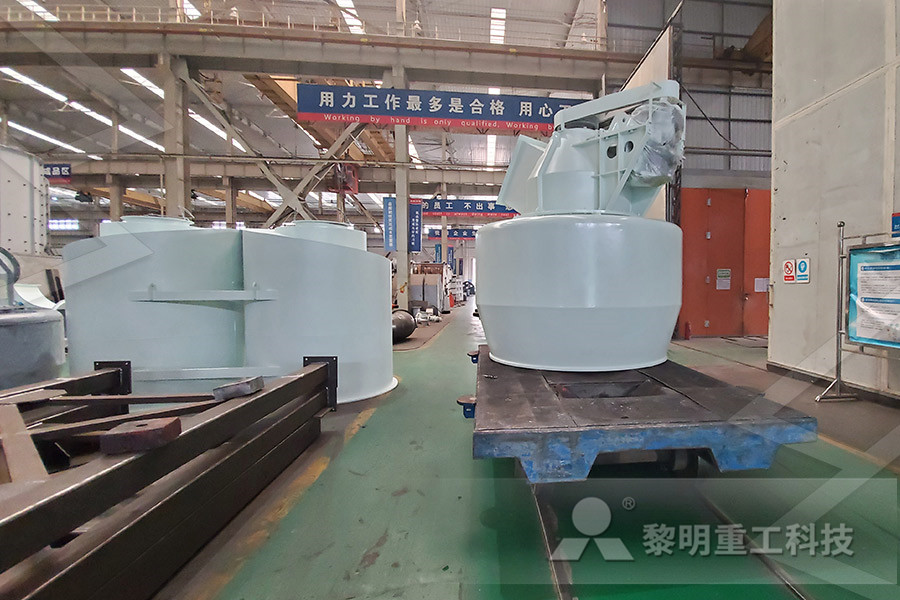

MCPT Series Cryogenic Grinder Machine ,MCPT Series

We also provide the lab type cryogenic grinder machine for customers who have just started production Produce highquality ultrafine powder Nitrogen inertness improves process safety High energy efficiency and small footprint Main motor power: 5555kw Input material size: ≤ 10mm Medium: Liquid Nitrogen Cooling Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, such as machining and stamping There are various kinds of cutting fluids, which include oils, oilwater Cutting fluid Wikipedialiquid nitrogen whilst acts as a protective shielding, can also provide high cooling rates to promote metallurgical changes However, these advantages have not been explored in grinding This paper proposes an innovative development of grinding–hardening technology using liquid nitrogen to integrate precision surface grinding Grindinghardening with liquid nitrogen: Mechanisms and (4,5) Nguyen and coworkers studied the microstructure, hardness, and residual stress development of a grindhardened layer using cooling media, such as dry air and liquid nitrogen, (6) and (PDF) Grindinghardening with liquid nitrogen: Mechanisms Cryogenic technology for product cooling It is necessary to use liquid nitrogen in cryogenic grinding processes to produce very highquality powders The material to be milled is sent from the feed hopper through the dosing screw to the paddle screw cooler Liquid nitrogen Cold grinding and recycling Messer Group

A New GrindingHardening Technology Using an Inert Cryogen

that liquid nitrogen has successfully acted as a protective shielding in grinding 33 Heating mechanism in the grinding zone All the above show that liquid nitrogen is a superior cooling medium During grinding, the abrasive particles and chips are formed, and the lubricating effect of the abrasive particles and the machining surface is formed 6 Selfaccelerating method By using the principle of liquid dynamic pressure, the grinding fluid can get a speed equal to the wheel cycle speed, thus producing a synchronous cooling How to use cooling in grinding process? PCD Tool Grinder The materials are cooled in a bath or screw type cooler, generally with liquid nitrogen Cryogenic grinding installations are used for gentle grinding of: Aromatic; Very oily; Greasy; or temperaturesensitive products; A cooling Cryogenic Grinding – Pallmann IndustriesDuring mill cooling, liquid nitrogen or carbon dioxide is sprayed directly into the grinder which lowers the temperature By suppressing the heat generated during grinding, this cooling technique ensures Cold Grinding messergroupAug 01, 2005 1 Introduction Abrasive processes, and grinding among them, are some of the oldest manufacturing methods known to man Yet grinding still accounts for about 25% of machining swarf in the industrialized world, and can produce high accuracy and excellent surface properties , New abrasive materials, new highperformance grinding machines and new manufacturing methods will allow grinding Mist jet cooling of grinding processes ScienceDirect

Cryogenic Grinding Study Mafia

Cryogenic grinding is a method of powdering herbs at subzero temperatures ranging from 0 to minus 70°F The herbs are frozen with liquid nitrogen as they are being ground This process does not damage or alter the chemical composition of the plant in any way Normal grinding processes which do not use a cooling Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, such as machining and stamping There are various kinds of cutting fluids, which include oils, oilwater Cutting fluid Wikipediagrinder which uses liquid nitrogen is shown This gives detailed idea of components of a typical cryogrinders It consists of grinding wheel, cover grinding wheel, Dynamometer, grinder tab, flexible pipe, Nozzle, pressure gauge, pressure valve, liquid nitrogen A Review on Cryogenic Grinding InpresscoApr 22, 2010 For a typical 1/4" shank burr run it at die grinder speed, 25,000+ rpm An advantage of using a burr instead of an abrasive wheel is there's no abrasive grit to deal with That can be particularly handy if one must use a nongrinding machine Machining Rubber? Practical MachinistFrostbites through liquid nitrogen – Liquid nitrogen has a temperature of –196 °C and may cause injuries similar to burns on skin or eye contact or cause frostbite • Always use goggles and wear protective gloves when opening the cooling casing and the grinding Manual Dewar LN2

How to Start Spices Cryogenic Grinding Unit in India

The auger not only transports the grinding media but also mixes with liquid nitrogen for greater cooling efficiencies The liquid nitrogen, a cryogenic fluid with a boiling temperature of –196 0 C absorbs heat from the material and vaporized to a gaseous state The nitrogen