Case

crushing in processing of ore

2021-06-14T08:06:29+00:00

Crushing of Ores and Rocks in Mineral Processing

In minerallurgy, crushing is the first mechanical step in the comminution process It allows reducing the mined ore size (up to 1 meter), until an acceptable size to undergo downstream treatment Therefore, it places in the exit of the MineIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral ProcessingMar 04, 2017 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of (PDF) SIZE REDUCTION BY CRUSHING METHODSApr 01, 2020 The process of metallurgy depends upon the nature of the ore and the impurities present in it S ome common steps involved in the metallurgical operations are : 1) Crushing and grinding of the ore 2) Concentration or benefaction of the ore 3) Extraction of crude metal from concentrated ore 4) Purification or refining of the metalCrushing, Grinding and Concentration of the Ore Jul 01, 2015 Crushing is accomplished by compression of the ore against rigid surfaces, or by impact against surfaces in a constrained motion path Grinding (and/or milling, which is COMMINUTION: Liberation, Crushing, Grinding

Crushing Grinding – The Anchor House, Inc

Sep 09, 2016 Crushing is performed in stages using a combination of jaw, cone and impact crushers and is performed dry The material is moved by mechanical means with conveyor belts Sometimes the blasting and crushing fines are washed off the ore, and pumped as a slurry directly to the grinding circuitOct 08, 2019 1 Crushing and grinding improvement The ore size reduction process involves two steps: crushing and grinding The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size meet Crushing and Grinding Process JXSC MachineCrushing and grinding are the two primary comminution processes Crushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material In comminution, the size reduction of Mineral processing WikipediaSep 09, 2016 Alternative processing routes must be investigated BLASTING The first stage of the crushing/grinding process in a production facility begins with blasting of the ore body, where the blasted material is composed of a very wide range of sizesCrushing Grinding – The Anchor House, IncThe process of gold ore processing and production mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness gold ore crushing, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency;Gold Ore Processing Solution Eastman Rock Crusher

Chemical Processing 101: Crushing Howard Industries

For example, a processing line at a mine may crush rock ore into smaller pieces before processing them further in a mill or grinder What Tools Are Used For Crushing? In the preindustrial era, crushers were usually handheld stones The weight of the stone would help give the user more power Querns and mortars are examples of the earliest When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec CanadaJan 15, 2019 This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant This system is specifically designed for the smallGold Ore Processing Plant, Crushing Quartz Hardrock Gold Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaAfter crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The beneficiation process should be as efficient and simple as possible, such as the development of energysaving equipment, and the best possible results with the most suitable processIron Ore Processing,Crushing,Grinding Plant Machine Desgin

iron ore crushing process conveyor drawing

drawing part of gold ore feeder apron feeder in iron ore mining crushing process Iron ore processing plant for blast furnace involves iron ore mining, iron ore crushing, large drilling rigs drill blast holes An apron feeder sends the ore Read More RCR is a leader in the design and manufacture of heavy duty apron feeders for the mining and process industriesMineral crushing, Ore processing Equipments Jaw crusher, cone crusher, vibrating feeder, vibrating screen, belt conveyor Live chat Send Message Send Introduction of copper ore Copper ore is a mineral form in which the copper element is mainly in the form of compounds, and a few exist in elemental form There are more than 200 kinds Copper Ore Crushing SHANGHAI SANME MINING MACHINERY Crushing is a multistage process and may use dry iron ore feed Typically, primary crushing andscreening take place at the mine site Primary crushing is accomplished by using jaw crusher or gyratorycrushers Primary crushing yields chunks of ore ranging in size from 6 to 10 inchesIron Ore Crusher Price, Crushing Machine for Iron Ore It is widely used to process gold ore, iron ore, chrome ore, copper ore, molybdenum ore, phosphate ore, feldspar ore, fluorite ore, cobalt ore, graphite, coal from stone crushing to extraction of ore powder to improve ore grade # goldore # ore # mineral # mining # ballmill # oreprocessingplant See MoreGold Ore Beneficiation Vian Shi FTM Company FacebookJul 01, 2015 Crushing reduces particle size of runofmine ore to such a level that grinding mill can further grind it until the mineral and gangue is substantially produced as separate MINUTION: Liberation, Crushing, Grinding

Mineral Processing Part 1 Geology for Investors

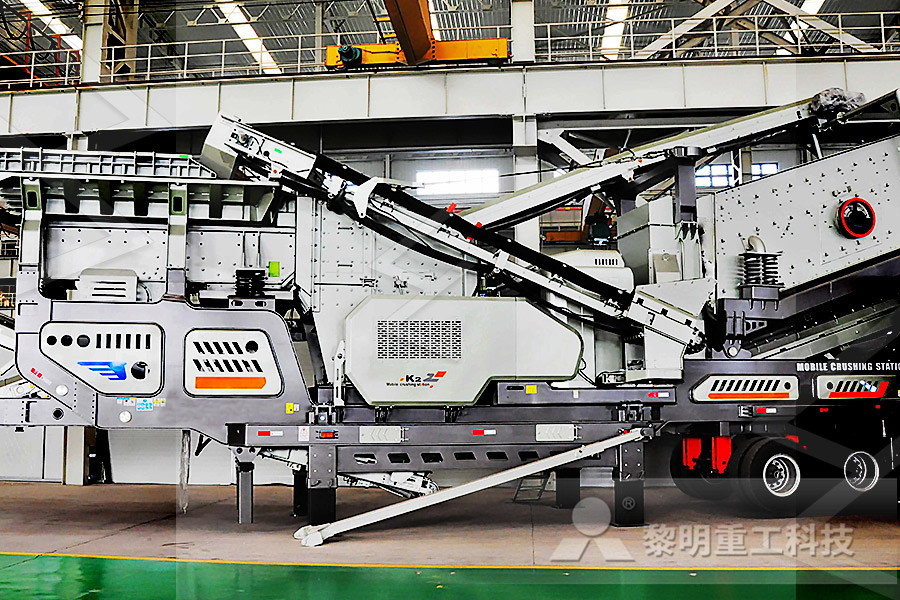

Mar 01, 2021 Most ore, however, is contained within hard rock that requires heavy duty crushing Mobile jaw crushing machine processing ore The goal of comminution is to crush the ore into small particles that contain only one mineral Dry crushing ore to ~15 mm particles is carried out on crude ore by compression and impact forceWhen the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec CanadaThe number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersDesign of a crushing system that improves the crushing Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) Overview of Mineral Processing MethodsCrushing is done in stages to “gently” free the diamonds from the kimberlite rock and produce a target size, usually less than 25 mm, for further processing You don’t want the pieces to be too small, because you don’t want to crush the diamonds! 2 Screening Ore is sized using vibrating screens after each crushing The 5 Main Steps in Processing Diamond Ore Multotec Canada

Importance Of Crushing Ore avsbouwdenhaagnl

Crushing of ores and rocks in mineral processing ,In order to obtain the regular size crushed ore for the beneficiation or subsequent use, primary crushing is followed by secondary crushing, or even tertiary crushing or even quaternary, are installed in the metallurgical plant primary crushing the primary crusher is a machine designed to reduce the size of large rocks from the mine at cmIn ore enrichment, two, three, or four stages of crushing are used, and the unit expenditure of energy to crush pieces of material 9001,200 mm in size into pieces 25 mm in size is 1530 kWhr per ton of oreCrushing Article about Crushing by The Free DictionaryMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannicaore crushing plant ores crusher for ore crushing processing MTW Series Heavy Type European Grinding Output size : 160045 mm, the fineness is 0038mm Production capacity : 3545T/H PROCESSED MATERIALS limestone, calcite, barite, dolomite, potassium feldspar,ore crushing plant ores crusher for ore crushing processingJan 02, 2020 copper mining and processing: processing of copper ores following mining, transporting, and crushing to a consistent gravel or golf ballsize, the crushed ore is piled into a heap on top of an impenetrable layer, on a slightcopper extraction wikipediathe processing techniques depend on the nature of the ore if the ore is primarily sulfide copper minerals (such as chalcopyrite), the ore crushing process of copper ore southportline

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Today we set up the crushing wheels and an automated ore processing setup to go along with it The crushing wheels give us crushed ore, which is then washed Surviving With Create 03 :: E04 Crushing Wheels Ore Iron Ore Processing Plant Xinhai raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smallerore crushing description