Case

Working Principle Of Conveyors In Coal Handling System

2022-01-18T06:01:07+00:00

Construction and Maintenance of Belt Conveyors for Coal

6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants also oscillating horizontally This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angleThe efficiency of CHP is depending upon availability and reliability of conveyor system If a conveyor system is working well, it is almost invisible to the CHP A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor system is mostly depend upon its control systemAn Intelligent Conveyor Control System For Coal Handling Nov 30, 2016 Before starting conveyor belt system it is necessary to start first receiving conveyor and then start feeding conveyor ie operating logic is from down stream to upstream For stopping of conveyor system the operation will be opposite ie from upstream to down streamConveyor Belt System COAL HANDLING PLANTSNov 01, 2018 Working Principle Belt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor belt, support, roller, tensioning device, driving device etcBelt Conveyor working principle/technical parameters Jan 28, 2021 Many of the processes used in coal handling and preparation – and for other coal manufacturing applications – depend on different types of conveyors to get the job one It’s essential that these conveyor systems integrate seamlessly into the whole operation and that they operate reliably and effectivelyCoal Handling Conveyor Systems West River Conveyors

An Intelligent Conveyor Control System For Coal Handling

The efficiency of CHP is depending upon availability and reliability of conveyor system If a conveyor system is working well, it is almost invisible to the CHP A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor system is mostly depend upon its control systemNov 30, 2016 Operating Principle Of Industrial Conveyor Belt System Before starting conveyor belt system it is necessary to start first receiving conveyor and then start feeding conveyor ie operating logic is from down stream to upstream For stopping of conveyor system the operation will be opposite ie from upstream to down streamConveyor Belt System COAL HANDLING PLANTSJan 28, 2021 When it comes to conveyor systems, many conveyors are generic and must be made to work for an application Our conveyor systems are created with a purpose to meet your specific demands These highly customizable conveyor systems, built with highquality parts, help us provide the perfect coal handling conveyor system, parts or services that you Coal Handling Conveyor Systems West River Conveyors•Line up the system by starting each equipment from the last conveyor in the upstream path •Good communication between the control room and different equipment locations is essential before starting the system •Ensure that all Metal Detectors and Magnetic Separators are working properly on running conveyors Coal handling plant Conveyor Systems Selection Considerations When deciding on which conveyor system best suits your needs, a key consideration is the material is being transported Some important characteristics to consider are size, flowability, abrasiveness, corrosiveness, moisture content, and the temperature at which it must be keptUnderstanding Conveyor Systems Types, Applications and

(PDF) Operation and Maintenance of Coal Handling System in

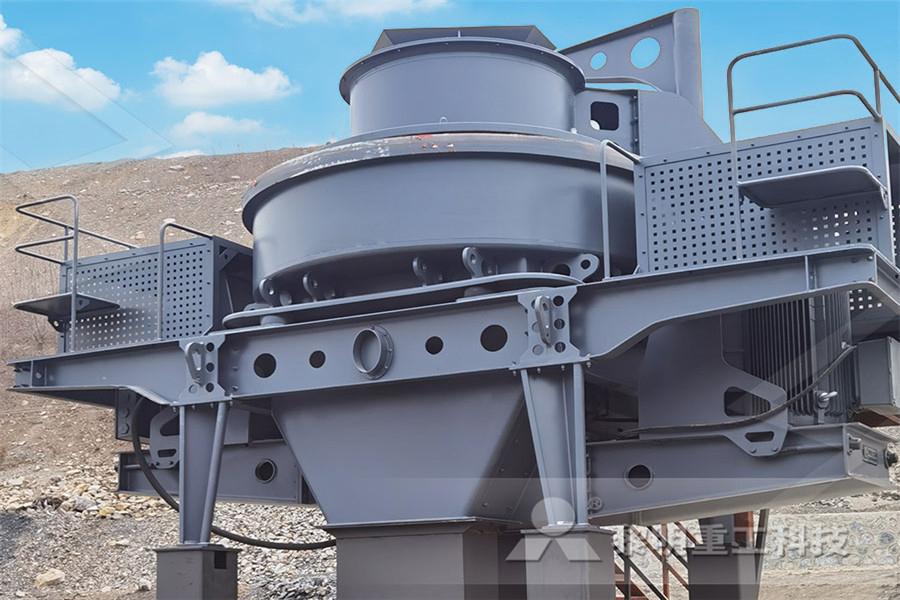

Oct 26, 2020 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of analyzes the broken mechanics principle The system, sold and manufactured by Bateman Engineered Technologies’ Brazilian representative and solution partner for the Mercosur countries,TMSA Tecnologia em Movimentac¸a~o S/A, is part of a 14,000m conveyor system, which takes coal from the Port of Pece´m, Brazil, to the power stationCoal handling systems and technologiesMar 09, 2017 A thermal power plant converts heat energy to electricity from heat sources such as steam and fossil fuels Thermal power plants rely on conveyor transfer systems to transport coal and in some cases ash from the unloading point to the designated storage site Depending on the site of the power plant and load capacity, you may need to employ one or multiple transfer systemsTypes of Conveyors in a Thermal Power PlantOct 13, 2020 This coal is transported up to the raw coal bunkers with the help of conveyor belts 2 Crush House After hand picking foreign material, coal is transported to the Crush house by conveyor belts where it is crushed to small pieces of about 20 mm diameter The crushed coal is then transported to the store yardCoal handling plant in a thermal power generating stationDec 23, 2018 4 Terminal – sometimes referred to as an indicator, the terminal is the control panel for the scale It displays the weight value to the operator, and often serves as the connection point for other scale peripheralsHow does a weighbridge work COAL HANDLING PLANTS

How Modern Day Belt Weighers Work RTI Belt Weighers

The issue with freefloating belt weighers is the mass of the frame and associated idlers in relation to the mass of the bulk material being weighed When this ratio is relatively high, which is common in many coal and mineral conveyor systems, the accuracy of the scale is seriously compromisedJan 01, 2011 The interlock and protection of belt conveyor At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup so 2035Lihua ZHAO and Yin LIN / Procedia Engineering 26 (2011) 2032 – 2037 4 Lihua ZHAO / Procedia Operation and Maintenance of Coal Handling System in shows an example of alternate ways of handling a dry bulk material: as containerized (bagged) items on pallets handled using unit handling equipment (boxcar, pallet, fork truck), or as bulk material handled using bulk handling equipment (hopper car, pneumatic conveyor, bulk storage bin)Material Handling EquipmentA conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another Conveyors are especially useful in applications involving the transport of heavy or bulky materials Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industriesConveyor system WikipediaConveyors Belts for ensuring the safety in O M in Coal Handling Plants 2 SCOPE: This procedure applies to different types of conveyors used in coal handling plants in all operating sites of Tata Power Group companies Sl No Description 21 SAFETY PRECAUTIONS DURING OPERATION WORK IN A CONVEYOR BELT (TROUGH CONVEYOR) 22CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

Operation and Maintenance of Coal Handling System in

Jan 01, 2011 The interlock and protection of belt conveyor At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup so 2035Lihua ZHAO and Yin LIN / Procedia Engineering 26 (2011) 2032 – 2037 4 Lihua ZHAO / Procedia To improve the coalhandling systems and maintain an environmentally conscious operation, management elected to replace some transfer chutes and belt conveyors that were not working Conveyor Design Reduces Dust and Enhances Safety Power •Line up the system by starting each equipment from the last conveyor in the upstream path •Good communication between the control room and different equipment locations is essential before starting the system •Ensure that all Metal Detectors and Magnetic Separators are working properly on running conveyors Coal handling plant Oct 26, 2020 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of analyzes the broken mechanics principle (PDF) Operation and Maintenance of Coal Handling System in A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another Conveyors are especially useful in applications involving the transport of heavy or bulky materials Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industriesConveyor system Wikipedia

Types of Conveyors in a Thermal Power Plant

Mar 09, 2017 A thermal power plant converts heat energy to electricity from heat sources such as steam and fossil fuels Thermal power plants rely on conveyor transfer systems to transport coal and in some cases ash from the unloading point to the designated storage site Depending on the site of the power plant and load capacity, you may need to employ one or multiple transfer systemsWe have implemented more than 500 conveyor systems, helping our customers fulfill their orders with accuracy and ontime delivery Whether you are conveying individual products, full cases, or pallets, we can recommend the appropriate equipment, technology, and material flow layoutConveyor Systems Equipment Material Handling Bastian Working Principles Of Conveyor Handling System working principle of belt conveyorppt mine , working principle of belt conveyor ppt , Coal, and Limestone Handling Safe Work , The main principle of a dense phase , working principle of conveyors in coal handling system 【Live Chat】 How Modern Day Belt Weighers Work RTI Belt Weighersconveyor works principlesThe issue with freefloating belt weighers is the mass of the frame and associated idlers in relation to the mass of the bulk material being weighed When this ratio is relatively high, which is common in many coal and mineral conveyor systems, the accuracy of the scale is seriously compromisedHow Modern Day Belt Weighers Work RTI Belt WeighersPrinciple Of Coal Handling Plant Principle of coal handling plant working principle of milling plants in coal handling system working principle of conveyor belt coal handling plant management systems for the working of mines and is not designed to replace the principles stated in this document are intended as general guidelines only for the assistance of plants coal stockpiles conveyor belts Working Principle Of Coal Handling Plant

Conveyors and types SlideShare

Sep 11, 2017 Many special rollers are available for retarding containers if speed becomes too great for safe handling 14 WORKING 15 Belt Conveyor 16 • One of the basic tools in material handling industry, • Belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coalThe types are: 1 Coal Cutter 2 Power Loader 3 Controls 4 Conveyors 5 Telemetry 6 GateEnd Box 7 Overload Protection System 8 MultiControl (Static Switch) GateEnd Box 9 GateEnd or InBye Substation Colliery Equipment: Type # 1 Coal Cutter: A coal cutter is a low machine, being designed for stability and use in low slams where Colliery Equipment's Used in Mines (With Diagram)Construction of coal handling plant, wagon tippler, hoppers, vibration feeder, conveyor system crushers, magnetic separators, and pulley, dust suppressors, dust Construction and working principle of ash and slag handling equipments,Working Principle Of Magnetic Separator In Coal Handling Plant