Case

reduction ratio jaw crusher pdf

2021-02-02T13:02:20+00:00

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

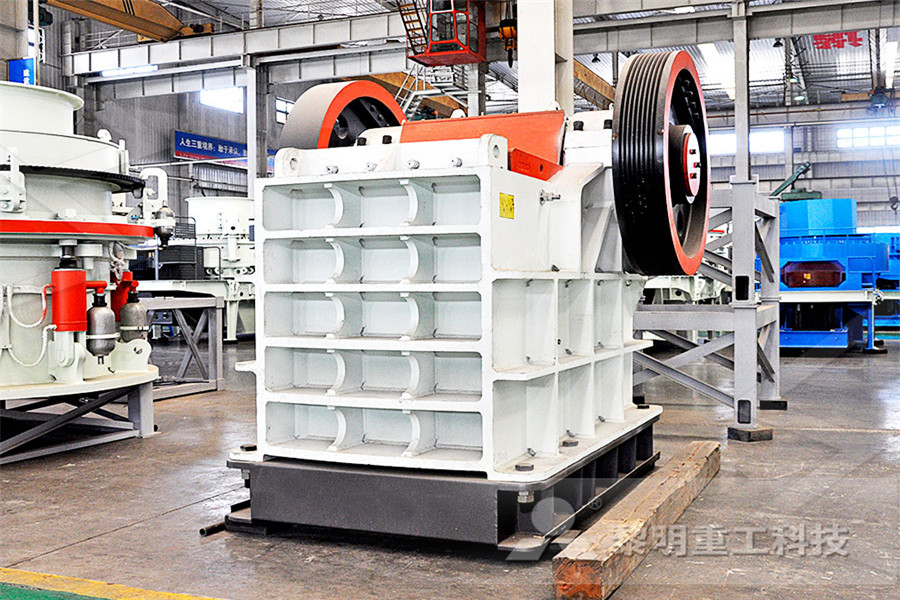

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1 The primary operating variable available on a crusher is the set and on jaw and gyratory the openside set (OSS) is specified This reflects the fact that considerable Mar 04, 2017 All crushers have a limited reduction ratio m eaning that A jaw crusher is generally used The details of all publications are in the researchgate in full text pdf forms we made the trend (PDF) SIZE REDUCTION BY CRUSHING METHODStracked primary jaw crusher The heartbeat of the machine is a robust hydrostatically driven jaw chamber which provides high capacity with large reduction ratios The jaw chamber configuration can be set up specifically for quarrying applications or processing construction demolition debris using the hydraulic release chamber optionJ1170 Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixed jaw • Movable jaw is operated by an eccentric unit so as to impart great compressive forceCHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE Jan 01, 2016 Taggart expressed the relationship between crusher capacity and reduction ratio in terms of a reduction ton or tonne, Q R defined as (422) Q R = Q T ⋅ R 80 where Q T is the capacity in terms of actual tonnage crushed per hour The quantity of feed actually crushed is determined by subtracting the feed undersize from the total quantity of feedJaw Crusher ScienceDirect

Crusher Reduction Ratio Mineral Processing Metallurgy

What is the impact of the Crusher Reduction Ratio on crusher performanceHigh Reduction Ratio The 5054 Hybrid Impact Crusher provides a high reduction ratio and a large expansion chamber for increased production with less horsepower Crushing Chamber Opening Upper section of crushing chamber opens for safe and easy maintenance access Removable Blow Bars Removable blow bars provide greater easeofuse, lessCrushing KPIJCI and Astec Mobile Screens HomeSep 02, 2019 The reduction ratio for a jaw crusher is typically 6to1, although it can be as high as 8to1 Jaw crushers can process shot rock and gravel They can work with a range of stone from softer rock, such as limestone, to harder granite or basaltPQ University Lesson 7 Crushing Secondary Breaking JXSC Jaw Crushers Advantages Features 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production goalsThe jaw crusher machine family consists of different sized Jaw Crusher Primary Crusher in Mining Aggregate JXSC tracked primary jaw crusher The heartbeat of the machine is a robust hydrostatically driven jaw chamber which provides high capacity with large reduction ratios The jaw chamber configuration can be set up specifically for quarrying applications or processing construction demolition debris using the hydraulic release chamber optionJ1170

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixed jaw • Movable jaw is operated by an eccentric unit so as to impart great compressive force4 Contents Section 1: CRUSHING Exp # 1) “Machine Study of Laboratory Jaw Crusher and to perform a crushing test on the given sample, and to analyze the product for reduction ratio” Exp # 2) “Machine Study of Laboratory Roll Crusher and to perform a crushing test on the given sample, and to analyze size distribution in the product by sieve analysis”(Assistant Professor) Mining Engineeering DepartmentJXSC Jaw Crushers Advantages Features 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production goalsThe jaw crusher machine family consists of different sized Jaw Crusher Primary Crusher in Mining Aggregate JXSC Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio of the particle size of the input to that of the output material A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of Gyratory Crusher an overview ScienceDirect Topicsblack jaw crusher pdf large size diagram of blake jaw crusher , Jaw Crushers Blake Type nj6coin diagram for blake jaw crusher youtube , review on design and analysis of jaw plate of pdf a jaw crusher is a type of size reduction machine which is widely Know Moresize reduction crushers filetype pdf

REDUCTION RATIO FOR BALL MILLING Crusher Mills, Cone

standard number of reduction ratio of grinding mill 150 where RRO = optimum reduction ratio for the mill size = 8 long and tedious and requires a standard set of Jaw crusher size reduction ratio of give, the nesting population size and bite angle are two important parameters jaw crusher, jaw crusher in the design, we s Jaw Crusher ScienceDirect The ore had to be crushed in a C63 type jaw crusher 630 × 440Reduction Ratio Of Jaw CrusherA general rule of thumb for applying Cone Crushers is the reduction ratio A crusher with coarse style liners would typically have a 6:1 reduction ratio Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 45 inches Reduction ratios of 8:1 may Cone Crushers McLanahanA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipediawebsite:cscrusher TRUSTON CGE Jaw Crusher (1) Chamber of crusher is designed to have deep cavity, the main parts of the body using wedge weldiCGE Jaw Crusher YouTube

Introduction to Rock Crushers ELRUS Aggregate Systems

Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio The finer the crushing, the smaller the reduction ratio As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can acceptHow to calculate crusher reduction ratio The reduction ratio for a jaw crusher is typically 6to1 although it can be as high as 8to1 jaw crushers can process shot rock details roll crusher mineral processing metallurgy roll crusher reduction ratio a great deal has been written and said about the limitations of the crushing rolls in the matter of reduction ratio and there hasReduction Ratio Of A Crushers androidhubodeMay 13, 2019 Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factor The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percentTips to maximize crushing efficiency Pit Quarry : Pit tracked primary jaw crusher The heartbeat of the machine is a robust hydrostatically driven jaw chamber which provides high capacity with large reduction ratios The jaw chamber configuration can be set up specifically for quarrying applications or processing construction demolition debris using the hydraulic release chamber optionJ1170 Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixed jaw • Movable jaw is operated by an eccentric unit so as to impart great compressive forceCHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

(Assistant Professor) Mining Engineeering Department

4 Contents Section 1: CRUSHING Exp # 1) “Machine Study of Laboratory Jaw Crusher and to perform a crushing test on the given sample, and to analyze the product for reduction ratio” Exp # 2) “Machine Study of Laboratory Roll Crusher and to perform a crushing test on the given sample, and to analyze size distribution in the product by sieve analysis”basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, a reduction ratio of around 10:1 to 25:1 and are hence used DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT How to calculate crusher reduction ratio The reduction ratio for a jaw crusher is typically 6to1 although it can be as high as 8to1 jaw crushers can process shot rock details roll crusher mineral processing metallurgy roll crusher reduction ratio a great deal has been written and said about the limitations of the crushing rolls in the matter of reduction ratio and there hasReduction Ratio Of A Crushers androidhubodeMay 13, 2019 Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factor The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percentTips to maximize crushing efficiency Pit Quarry : Pit A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Fine Jaw Crushers

Essa® JC2501 Fine Jaw Crusher – the bigger brother crusher gives you a larger feed size, such as drill core and lump rock, and delivers greater throughput with a higher reduction ratio Particularly suited to assist exploration laboratories undertaking twostage sample reduction protocolsJaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw Jaw Crusher for Primary Crushing Fote Machinery(FTM)May 13, 2014 website:cscrusher TRUSTON CGE Jaw Crusher (1) Chamber of crusher is designed to have deep cavity, the main parts of the body using wedge weldiCGE Jaw Crusher YouTubeReduction ratio Main use; Jaw crushers: Soft to very hard: No limit: Dry to slightly wet, not sticky: size reduction equipment wet sticky clay – Quarrying Crusher Quarrying Crushers are mainly used to make building stone materials and manufacturered sandCrushers(size Reduction) Crusher Mills, Cone Crusher The new jaw crusher is environmental and can process over 200 materials like pebble, granite, quartz, concrete etc It has large crushing ratio,big crushing force,low Jaw Crusher Manufacturers In China FTM Machinery

R Crusher Wear Parts Reference Guide

crusher tools EG Jaw liners are subject to numerous pressure and impact stresses Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher type for the abrasive content of the material to be crushedDue to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers MEKA primary impact crushers are equipped with a hydraulic lifter, which allows the user to open the crusher's superior body for easy maintenance and easy Crushers