Case

formula for table output rpm of vertical raw mill

2023-07-08T13:07:59+00:00

Common Formulas for Milling Operations Speed, Feed, SFM

Calculate RPM, IPM, SFM, IPT and more Below are variable abbreviations and formulas for many common milling operations Click here to download a printable PDF file containing these formulasMilling Equations Machining Time : Peripheral Milling T m = L + A f r T m = Machining Time (Min) L = Length of Cut A = Approach Distance f r = Feed Rate (Dist/ Min) Machining Time : Face Milling T m = f r L + A + O T m = Machining Time (Min) L = Length of Cut A = Approach Distance O = Cutter Run Out Distance f r = Feed Rate (Dist/ Min) 4Milling Equations Montana State UniversityFor vertical mills the dam ring height is often referred to as "% of table diameter" The optimum height normally being in the range 25 4% of table diameter Example: A dam ring of 120 mm in an Atox 325 will give a relative height of: 120 mm / 3250 mm = 37%Vertical Mill Calculations Mill (Grinding) NozzleThe Milling Process – Definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap)This value is necessary for determining the true cutting data at the actual depth of cut (a p)This is a particularly important value when using round insert cutters Milling Formulas and Definitions Sandvik CoromantRPM = revolutions per minute For Example: Feeds for end mills used in vertical milling machines range from 001 to 002 in feed per tooth for very small diameter cutters on steel work material to 010 in feed per tooth for large cutters in aluminum workpiecesUnit 2: Speeds, Feeds, and Tapping – Manufacturing

Milling Speed and Feed Calculator How to Calculate

The RPM calculated in the Mill Speeds and Feeds Calculator refers to the spindle speed in milling process, and IPM refers to feed rate The exact RPM is not always needed, the following calculator (formula) may be used to estimate the value closely Cutting speed (SFM): the rate at the workpiece surface, irrespective of the machining operation May 15, 2013 Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareWhat is the table feed when feed per tooth is 01mm/t, number of insert is 10, and main axis spindle speed is 500min1? (Answer) Substitute the above figures into the formula vf=fz×z×n=01×10×500=500mm/min The table feed is 500mm/minFormula for Face Milling MITSUBISHI MATERIALS CORPORATIONsaved annually for OK mill owners The OK raw mill is designed according to the same design principles The OK™ mill can be operated with a number of rollers out of service, minimising the risk of lost production The use of concrete stands saves installation time and reduces the total installed costOK™ mill The most reliable and efficient mill for raw and The TRANSPOSE function is fully automatic and can transpose cells vertical to horizontal, and vice versa The only requirement is that there be a one to one relationship between source and target cells In the example shown, we are transposing a table that is 2 columns by 7 rows (14 cells), to a table that is 7 columns by 2 rows (14 cells)Excel formula: Flip table rows to columns Exceljet

Cutting Speeds RPM Calculations

Spindle speed settings on the drill press are done in RPMs To calculate the proper RPM for the tool, we must use the following formula: Cutting speed (CS) X 4 Diameter of cutter (D) This simplified version of the RPM formula is the most common formula used in machine shops This RPM formula can be used for other machining operations as wellRPM = revolutions per minute For Example: Feeds for end mills used in vertical milling machines range from 001 to 002 in feed per tooth for very small diameter cutters on steel work material to 010 in feed per tooth for large cutters in aluminum workpiecesUnit 2: Speeds, Feeds, and Tapping – Manufacturing For vertical mills the dam ring height is often referred to as "% of table diameter" The optimum height normally being in the range 25 4% of table diameter Example: A dam ring of 120 mm in an Atox 325 will give a relative height of: 120 mm / 3250 mm = 37%Vertical Mill Calculations Mill (Grinding) NozzleSurface feet per minute (SFPM or SFM) is the combination of a physical quantity (surface speed) and an imperial and American customary unit (feet per minute or FPM)It is defined as the number of linear feet that a location on a rotating component travels in one minute Its most common use is in the measurement of cutting speed (surface speed) in machiningSurface feet per minute WikipediaThe output of a rotating body is obtained from the product of torque and angular speed P = Output in N•m/s (1N•m/s = 1 W = 000136 metric hp) M = Torque in N m ω = Angular speed in s1 N = Rotational speed in rpm Transformation and some other steps give the relationship for torqueTorque Measurement in Wind Turbines HBM

Vertical Axis Wind Turbine an overview ScienceDirect

The rotor operates between 160 and 250 rpm, with corresponding flows of 10 to 15 ℓ/s at a lift of 15 m The wind turbine becomes overloaded when revolutions per minute drops below 160 and will stall Stall occurs at windspeeds below 5 m/s When operating near 20m/s windspeed, aerodynamic brakes deploy and slow the turbineFormula: Run Time / Planned Production Time Example: 373 minutes / 420 minutes = 08881 (8881%) Performance Performance is the second of the three OEE factors to be calculated It accounts for when the process is running slower than its theoretical top speed (both Small Stops and Slow Cycles) Formula: (Ideal Cycle Time × Total Count) / Run Calculate OEE – Definitions, Formulas, and Examples OEEKnown variables: Weight (lbs), Linear Velocity (ft/min), Speed of Driving Motor (RPM), Change in Speed (RPM), and Time to Accelerate Total System (sec) In addition to the torque required to drive the load at a steady speed, torque is required to accelerate the loadMotor Torque Calculations NEPSIThe TRANSPOSE function is fully automatic and can transpose cells vertical to horizontal, and vice versa The only requirement is that there be a one to one relationship between source and target cells In the example shown, we are transposing a table that is 2 columns by 7 rows (14 cells), to a table that is 7 columns by 2 rows (14 cells)Excel formula: Flip table rows to columns ExceljetThe design and manufacture of pharmaceutical tablets is a complex multistage process whereby formulation scientists ensure that the correct amount of drug substance in the right form is delivered at the appropriate time, at the proper rate and in the desired location with its chemical integrity protected to that point Most drug substances do not possess the required properties which give Manufacture of Pharmaceutical Tablets Pharmapproach

OPTIMAL ROTOR TIP SPEED RATIO mragheb

The choice of the tip speed ratio for a particular wind turbine design depends on several factors In general a high tip speed ratio is a desirable feature since it results in a high shaft rotational speed that is needed for the efficient operation of an electrical generator A high tip speed ratio however entails several possible disadvantages: 1Sep 22, 2018 Specific Speed of Pump The specific speed “Nq” is a parameter derived from a dimensional analysis which allows a comparison of impellers of various pump sizes even when their operating similar Q H range The specific speed can be used to classify the optimum impeller design Specific Speed of pump (Nq) is defined as the speed in RPM at which a geometrically similar impeller Pump Power Calculation Formula Specific speed of a The UMC750 has an integrated dualaxis trunnion table with a 500 mm diameter platter that features standard Tslots and a precision pilot bore for fixturing versatility The trunnion provides +120 and 35 degrees of tilt and 360 degrees of rotation to provide excellent tool clearance and large part capacityUMC750 5Axis Mill 40Taper Vertical Mills – Haas Table 1 shows the formula of a standard feed used in testing water stability of pellets It is typical of commercial catfish rations used in the southern part of the United States Basically it complies with the requirements of a 30 percent protein feed, 25 percent of which is of animal source, with a protein to calorie ratio of 90 (grams Chapter 18 Feed Milling ProcessesSpindle speed settings on the drill press are done in RPMs To calculate the proper RPM for the tool, we must use the following formula: Cutting speed (CS) X 4 Diameter of cutter (D) This simplified version of the RPM formula is the most common formula used in machine shops This RPM formula can be used for other machining operations as wellCutting Speeds RPM Calculations

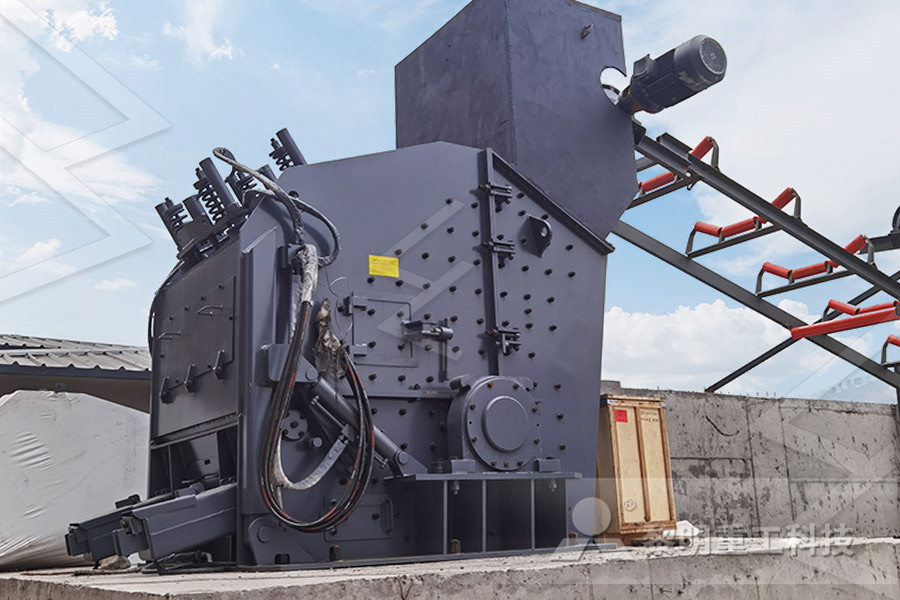

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Aug 08, 2013 Vane adjustment 2 Speed control 8/7/2013 8 Angle affects product sizing Rotor speed affects product fineness Rotor seal affects separator efficiency 8/7/2013 9 Used for reducing gas flow pressure lost over the mill (less pneumatic internal circulation) collecting conveyor fresh feed louvre ring scraper bucket elevator 8/7/2013 10VRM SlideShareTable 1 shows the formula of a standard feed used in testing water stability of pellets It is typical of commercial catfish rations used in the southern part of the United States Basically it complies with the requirements of a 30 percent protein feed, 25 percent of which is of animal source, with a protein to calorie ratio of 90 (grams Chapter 18 Feed Milling Processesroller and table profile that improve operating stability and reliability, giving a typical availability of 90 to 95 percent of scheduled ope rating time Due to its inherent flexibility, the mill can be operated with a number of rollers out of service and still achieve 60 to 70 percent of the nominal output, minimising the risk of lost productionOK™ cement mill The most energy efficient mill for The UMC750 has an integrated dualaxis trunnion table with a 500 mm diameter platter that features standard Tslots and a precision pilot bore for fixturing versatility The trunnion provides +120 and 35 degrees of tilt and 360 degrees of rotation to provide excellent tool clearance and large part capacityUMC750 5Axis Mill 40Taper Vertical Mills – Haas

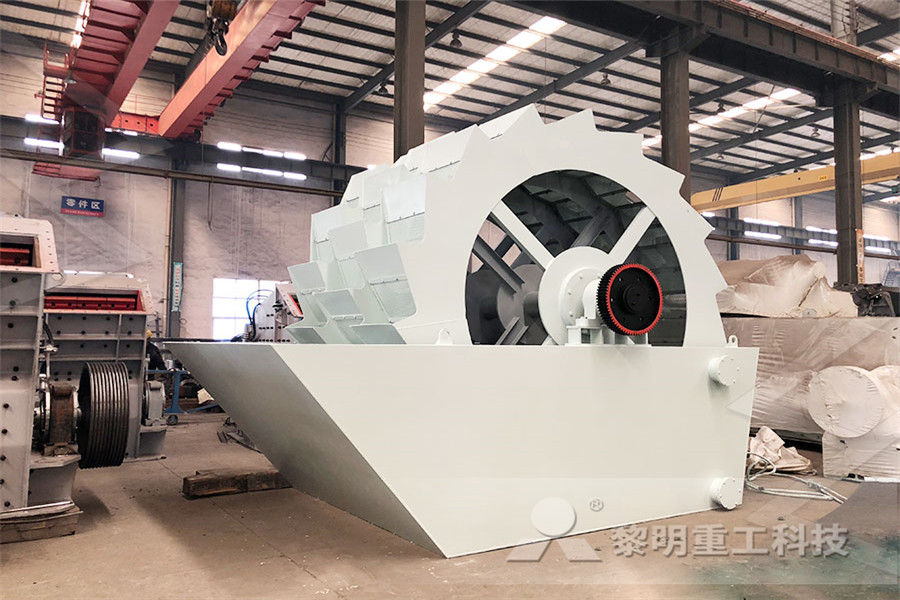

Pulverizer Wikipedia

Vertical spindle roller mill Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal These mills are usually found in utility plants Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and tableSep 22, 2018 Specific Speed of Pump The specific speed “Nq” is a parameter derived from a dimensional analysis which allows a comparison of impellers of various pump sizes even when their operating similar Q H range The specific speed can be used to classify the optimum impeller design Specific Speed of pump (Nq) is defined as the speed in RPM at which a geometrically similar impeller Pump Power Calculation Formula Specific speed of a The choice of the tip speed ratio for a particular wind turbine design depends on several factors In general a high tip speed ratio is a desirable feature since it results in a high shaft rotational speed that is needed for the efficient operation of an electrical generator A high tip speed ratio however entails several possible disadvantages: 1OPTIMAL ROTOR TIP SPEED RATIO mraghebThe design and manufacture of pharmaceutical tablets is a complex multistage process whereby formulation scientists ensure that the correct amount of drug substance in the right form is delivered at the appropriate time, at the proper rate and in the desired location with its chemical integrity protected to that point Most drug substances do not possess the required properties which give Manufacture of Pharmaceutical Tablets Pharmapproachturbines include vertical axis or horizontal axis wind turbines The turbines are classified upon how the shaft of the generator is mounted The horizontal axis wind turbine HAWT was invented before the vertical axis wind turbine (VAWT), which led to its popularity and wide use Figure 12 shows a diagram of these two types of systemsVertical Axis Wind Turbine Evaluation and Design

Vertical 3Axis Makino

Experience chatterfree cutting; agility for highspeed hard milling; and more accuracy for complex 3D geometry Go beyond traditional solutions Our Vertical 3axis machining center provides the flexibility to attack singlepiece production, development projects or complex, high volume mass productionAug 02, 2014 Tip speed ratio is a function of angular velocity, undisturbed wind speed and rotor radius In the design process of a verticalaxis wind turbine it is crucial to maximize the aerodynamic performance [22, 26] The aim is to maximize the annual energy production by optimizing the curve of the power coefficient varying with the tip speed ratio Design of a verticalaxis wind turbine: how the aspect The total wind power flowing into the turbine is defined by the fairly simple wind power formula, shown to the right The power into the turbine blads is a function of the wind speed to the 3rd power (V times V times V), air density, and swept area of the turbine blades A simple version of the wind power formula is shown to the rightWind turbine power coefficient definition and how it's used