Case

iso for crushing and sifting aggregate

2020-11-15T07:11:10+00:00

ISO ISO 202903:2019 Aggregates for concrete — Test

This document gives the determination of aggregate crushing value (ACV) of aggregates This gives a relative measure of the resistance of the aggregate crushing under the gradually applied compressive load The method is applicable to aggregates passing a 14,0 mm test sieve and retained on a May 01, 2003 B Specification 3138, Classes 5 and 6, stabilizing aggregate and aggregate bedding, have a required minimum percent crushing The percent crushing referred to in that specification is not the same as Sections 12146, 12147 or 12148 Differences are as follows: 1 Percent crushing can be determined by samples taken from1214 DETERMINATION PERCENTAGE OF CRUSHED PARTICLES No 2 coarse aggregate 220 lb No 5 coarse aggregate 110 lb No 8 coarse aggregate 55 lb No 9 coarse aggregate 35 lb No 11 No 12 coarse aggregate 25 lb No 43 coarse aggregate 110 lb No 53 coarse aggregate 135 lb No 73 coarse aggregate 80 lb 2 Inspection Sampling Procedures for Fine Coarse Crushing Powerful hammers or metal jaws within the primary crusher break the rock down Rock passes through a series of screens that sift it into different sizes It may also pass through further crushing stages Dry stone is delivered by road or rail from the quarryExtraction of Aggregates Process CEMEX USA CEMEXMechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling A method of separating solid particles according to size alone is called screeningMechanical screening Wikipedia

What is the Crushing value of Aggregates?? Firstalert

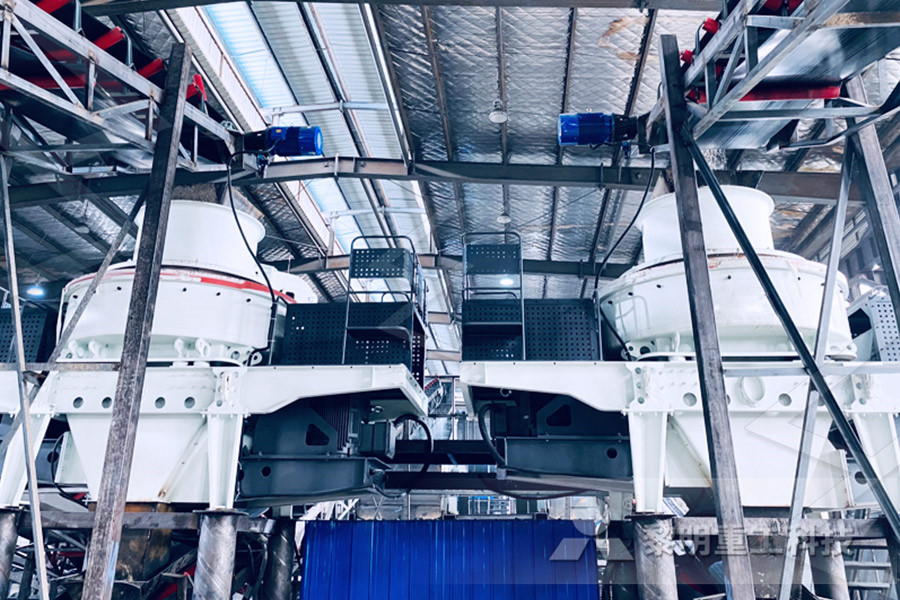

May 27, 2020 The aggregate crushing value should not be more than 45% by weight For aggregates used for concrete other than wearing surfaces and 30% by weight for concrete to be used as wearing surfaces such as runways, roads, and airfield pavements The natural stone processing uses a crushing and sifting process in different stages for producing defined size grains from big rock pieces Such classified fractions of final grain are used as aggregates for the concrete, the asphalt base, the binder and the surface layers of the course in the road construction as well as in the building Material Processing ResansilIso For Crushing And Sifting Aggregate Kimball equipment company is a supplier of crushing and screening equipment, systems and associated products for the aggregate, mining and industrial marketsWith an inventory of parts and related supplies in multiple locations, backed by factorytrained service personnel, the company can respond promptly Screening And Sifting EquipmentNov 11, 2019 Crushed stone often has an angular and jagged edge that occurs during the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to the effects of running water Unlike crushed stone, gravel is usually sold and used in its natural stateThe Complete Guide to Crushed Stone and GravelSep 09, 2018 This video (Animation, Animated Video) explains How to determine aggregate crushing value (Aggregate Crushing Strength) Aggregate test Coarse aggregate THow to determine Aggregate Crushing Value Aggregate

ISO ISO/TC 195 Building construction machinery and

Standardization in the field of Machines and equipment used on construction sites, including: concrete machines (eg batcher, mixer, pump, sprayer, transport, vibrator, floating) foundation machines (eg piling, diaphragm walling, earth boring, jetting, grouting, drill rigs for soil and rock mixture) As well as conventional crushing and screening, the aggregates processing component of the work also includes the Life Cycle impacts of excess production of fines, washing of recycled aggregates to enable further processing of fines and other aggregate sizes and the disposal options for inert construction and demolition wastes TheLife Cycle Assessment of AggregatesNo 2 coarse aggregate 220 lb No 5 coarse aggregate 110 lb No 8 coarse aggregate 55 lb No 9 coarse aggregate 35 lb No 11 No 12 coarse aggregate 25 lb No 43 coarse aggregate 110 lb No 53 coarse aggregate 135 lb No 73 coarse aggregate 80 lb 2 Inspection Sampling Procedures for Fine Coarse ISO Certified Golden Rock Aggregate received ISO 14001:2015, ISO 18001:2015 and ISO 9001:2015 crushed aggregates are made from crushing the stones from the mountain using specific methods and machinery to certain sizes crushed aggregates come in different shapes, colors, and sizes depending on the quarries and requirements for the GRA – Golden Rock Aggregate LLCNov 01, 2010 Consumption of natural aggregate as a largest concrete component is constantly and rapidly increasing with increasing of the production and utilization of concrete For example, three billions tons of aggregate are produced each year in the countries of European Union (European Environment Agency, 2008) This situation puts a question about the Comparative environmental assessment of natural and

DIFFERENT METHODS OF TESTING AGGREGATESpptx BY EARL

objectives • determine the aggregate crushing value of coarse aggregate; • assess suitability of coarse aggregates for use in different types of road • a steel cylinder cm diameter with plunger and base plate • straight metal tamping rid 16 mm diameter and 45 – 60 cm long rounded at one end • a balance of capacity 3 kg readable and accurate to one gram apparatusScreening/Sizing Sizing is the general separation of products according to their size The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to create various final productsScreening/Sizing McLanahanJob Description: 1) Operates concrete, asphalt, or sand and gravel plant to batch, crush, or segregate materials used in construction: Moves controls on panelboard or control board to heat, dry, and mix ingredients, such as asphalt, sand, stone, and naphtha, to produce asphalt paving materials; to weigh and mix aggregate, cement, and water to produce concrete; to control feeding, crushing, and GUNREDDY MANI KUMAR REDDY Mechanical Engineer To weigh and mix aggregate, cement, and water to produce concrete; or to control feeding, crushing, and sifting machinery in sand and gravel plant Observes gauges, dials, and operation of machinery to ensure conformance to processing specifications May repair machinery, using hand tools, power tools, and welding equipmentEugene Villafanca Plant Operator Qatar Alpha Beton Erskine is proud to offer a full range of skid steer attachments manufactured under our stringent ISO 9001:2015 certified quality processes View all of the attachments below or use the site navigation menu to view attachments by categorySkid Steer Attachments Erskine Attachments LLC

New mixedfleet telematics standard earns ISO approval

The mixedfleet telematics standard from the Association of Equipment Manufacturers and Association of Equipment Management Professionals has received approval from ISO, the International Organisation for Standardisation, to be accepted as a global standard The new ISO mixedfleet telematics standard enables equipment users to gather more original equipment makers equipment data into their The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect TopicsAS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant We also supply individual IsoTac Quarry stone crusher, aggregate vibrating screenwashing and sifting sand and gravel in usa,crushing Limestone Grinding Plant in Belgium As the finished product is for a paper making company, our buyer from Washing And Sifting Sand And Gravel In UsaStandardization in the field of Machines and equipment used on construction sites, including: concrete machines (eg batcher, mixer, pump, sprayer, transport, vibrator, floating) foundation machines (eg piling, diaphragm walling, earth boring, jetting, grouting, drill rigs for soil and rock mixture) ISO ISO/TC 195 Building construction machinery and

Cellular Glass Aggregate Serving as Thermal Insulation and

strength according to EN ISO 1295 71 is about 09 kPa and the friction angle is from approximately 40° to 50° The cavity space of the consolidated cellula r glass aggregate is about 30% according to one manufacturer Because of the base substance of the insulation glass the durability is assumed to be more than 50 years (CUAP 2003)The mixedfleet telematics standard from the Association of Equipment Manufacturers and Association of Equipment Management Professionals has received approval from ISO, the International Organisation for Standardisation, to be accepted as a global standard The new ISO mixedfleet telematics standard enables equipment users to gather more original equipment makers equipment data into their New mixedfleet telematics standard earns ISO approval ISO Certified Golden Rock Aggregate received ISO 14001:2015, ISO 18001:2015 and ISO 9001:2015 crushed aggregates are made from crushing the stones from the mountain using specific methods and machinery to certain sizes crushed aggregates come in different shapes, colors, and sizes depending on the quarries and requirements for the GRA – Golden Rock Aggregate LLCNov 01, 2010 The values given in Table 1 are the upper bounds of all the analyzed research data Unfortunately, there is a large experimental data scatter because the quality of RAC depends mostly on the quality of recycled aggregate, ie the quality of demolished concrete which is used for parative environmental assessment of natural and AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant We also supply individual IsoTac Quarry stone crusher, aggregate vibrating screen

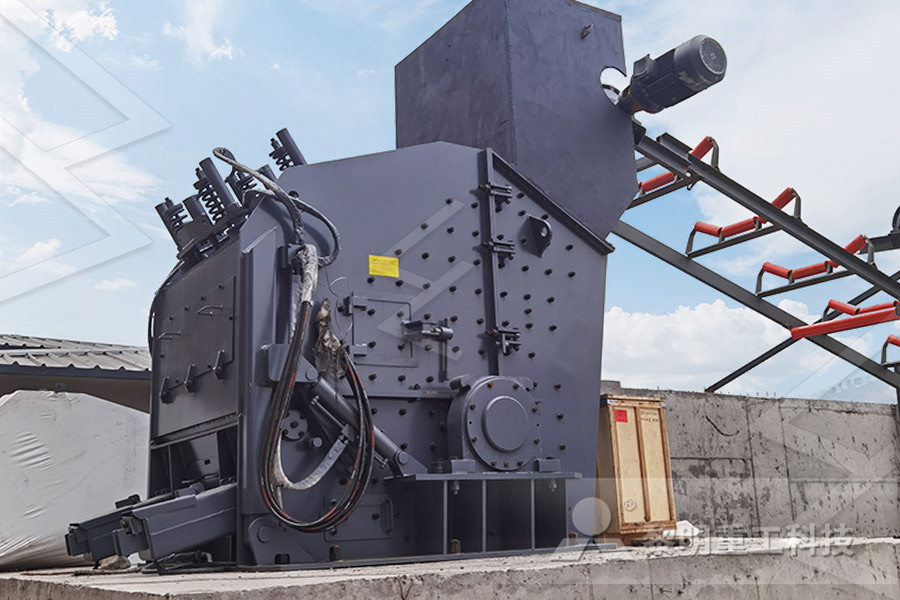

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Screening/Sizing Sizing is the general separation of products according to their size The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to create various final productsScreening/Sizing McLanahanJob Description: 1) Operates concrete, asphalt, or sand and gravel plant to batch, crush, or segregate materials used in construction: Moves controls on panelboard or control board to heat, dry, and mix ingredients, such as asphalt, sand, stone, and naphtha, to produce asphalt paving materials; to weigh and mix aggregate, cement, and water to produce concrete; to control feeding, crushing, and GUNREDDY MANI KUMAR REDDY Mechanical Engineer Erskine is proud to offer a full range of skid steer attachments manufactured under our stringent ISO 9001:2015 certified quality processes View all of the attachments below or use the site navigation menu to view attachments by categorySkid Steer Attachments Erskine Attachments LLCAbout ISO Group Overview and Mission Leadership Team Board of Directors ISO Group Locations News and Publications Careers Corporate Video Supply Chain Information Hub Extending Product Life Cycle ISO BLOG; NSN 67489, 89 SCREENING UNIT,AGGREGATE Federal Supply Classification crushing, grinding, screening, sifting National Stock Number NSN 67489 ISO Group

ASTM D7084 18 Standard Test Method for Determination of

51 This test method is a means of determining the crushing strength of a catalyst in a bed Techniques to measure the crushing strength of formed catalyst particles is limited to crushing of individual particles, which may not be related to how the catalyst will crush in a reactor or bedSep 26, 2017 Fractions of granite aggregate and their applications 5250 mm a large fraction of aggregates (processed after primary crushing) that is used as a basis for road surface @HASSAN HARRAZ 2017 AGGREGATE STONES 21 22 Fractions of granite aggregate and their applications 2070 mm, 4070 mm Alarge fractionAggregate stones SlideSharecharacteristics that constitute quality aggregate as it relates to this project These sections are then followed by a description of the aggregate production process, chronicling the drilling and blasting, crushing, sifting, cleaning, and stockpiling phases Following this process description the definition ofA Major Qualifying Report Submitted to the Faculty of