Case

result of wet ball mill in project

2020-08-07T05:08:44+00:00

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC

Jun 27, 2019 The difference between the result gotten from using wet and dry milling are most of the time very large This difference is attributed to the power The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball millMar 10, 2021 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material wellWhat are the Differences Between Dry and Wet Type Ball Mill?9 REPORTING TEST RESULTS 91 Report the Wet Ball Mill value to the nearest whole number Note 3—This test furnishes valuable supplementary data pertaining to the quality of the aggregate portion of flexible base material The Wet Ball Mill test is more reliable than the Los Angeles abrasion test in evaluating the quality of base materialsBALL MILL METHOD FOR DETERMINING THE To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to comment on someone else’s Ball mill vs wet pan mill Grinding Classification Sep 01, 2016 The lack of constraints in ball mill capacity in the published ball mill models may result in unrealistic predictions of mill throughput This paper presents an overfilling indicator for wet overflow discharge ball mills The overfilling indicator is based on the slurry residence time in a given mill and given operational conditionsAn overfilling indicator for wet overflow ball mills

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Overloading tends to accumulate fines at the toe of the mill which results in a cushioning effect When the rock load is low, excessive balltoball contact retards the rate of breakage The fraction of mill volume occupied by the ore, Wet Ball Mill = kg kWh = 016(A i0015) 033;Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsIn ball milling, the desired particle size is achieved by controlling the time, applied energy, and the size and density of the grinding media The optimal milling occurs at a critical speed Ball mills can operate in either a wet or dry stateBall Milling Material Milling, Jet Milling AVEKAA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaJul 05, 2020 View All Result Ball Mill by Pharmapproach July 5, 2020 in Particle Size Reduction Equipment 8 1 SHARES 197k VIEWS Share on Facebook Share on Twitter A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated Ball Mill: Operating principles, components, Uses

ball mill kailash wet grinders aprojectpl

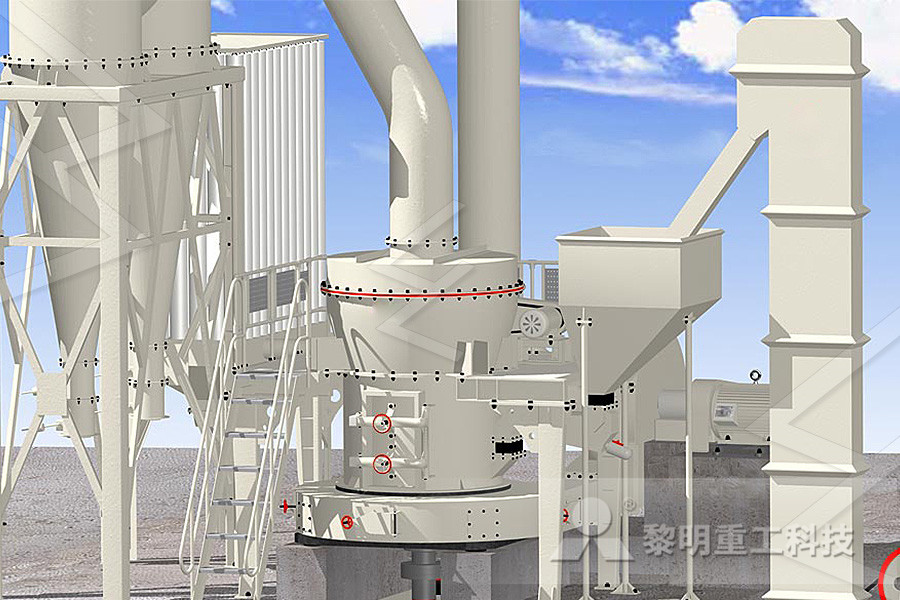

Ball Mill Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator Formula Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applications Some of those applications are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more ball mills Outotec Momentum Group HomeNov 30, 2020 The existing SAG mill will be retired The fourth ball mill, a 22 ft by 38 ft mill, will be installed adjacent to the third ball mill within the existing building With the addition of the fourth ball mill, the ball milling line will comprise four mills operating in parallel Two identical 24 ft x 30 ft mills, and two identical 22 ft x 38 ft millsCopper Mountain 65,000 t/d expansion approved including Ball Mill Manufacturer; Lab Ball Mill (Small Ball Mill ) Raw Vertical Mill; Coal Vertical Mill; Cement Ball Mill ; Cement Vertical Mill; Ore Ball Mill; Limestone Grinding Plant; Grinding Production Line; Coal Ball Mill; Dolomite Grinding Mill; Vertical Roller Mill; Raw Mill; Continuous Ball Mill; MQG Ball Mill; MQZ Ball Mill; Ceramic Ball Mill Ф900×1800 Wet Ball Mill for Russia Customer China Henan

Ball Mill,Grinding Ball Mill Equipment For Sale, Ball Mill

Wet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmThe hammer mill grinding system and the ball and race mill grinding system have been installed Testing of various coal samples has been underway in the air swept ball mill grinding system Modifications to the wet ball mill were delayed while an emergency repair of the sample preparation crusher was madeCoal grinding technology: a manual for process engineers The hammer mill grinding system and the ball and race mill grinding system have been installed Testing of various coal samples has been underway in the air swept ball mill grinding system Modifications to the wet ball mill were delayed while an emergency repair of the sample preparation crusher was madeDeveloping/modifying coal grinding procedures and Aug 21, 2020 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material project on artifitialore project on ball mill wet ball millDec 01, 2013 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry , , The ball mill process is very complicated process governed by many parameters, such as ball size, ball shape, ball filling, slurry loading (with respect to ball amount), powder loading with respect to the amount of total slurry Effect of ball size and powder loading on the milling

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Overloading tends to accumulate fines at the toe of the mill which results in a cushioning effect When the rock load is low, excessive balltoball contact retards the rate of breakage The fraction of mill volume occupied by the ore, Wet Ball Mill = kg kWh = 016(A i0015) 033;MicroDeval, wet ball mill, wet ball mill modified, Aggregate Crushing Value, Iowa Pore Index, Methylene Blue Value, sodium sulfate soundness, wateralcohol freezethaw soundness, point load strength, vacuum saturated bulk specific gravity, and vacuum saturated absorption Results from historical MoDOT test methods includedQuick Test for Durability Factor EstimationDec 12, 2016 Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 Ball Mill Design/Power Calculation LinkedInIn ball milling, the desired particle size is achieved by controlling the time, applied energy, and the size and density of the grinding media The optimal milling occurs at a critical speed Ball mills can operate in either a wet or dry stateBall Milling Material Milling, Jet Milling AVEKAView All Result Ball Mill by Pharmapproach July 5, 2020 in Particle Size Reduction Equipment 8 1 SHARES 197k VIEWS Share on Facebook Share on Twitter A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated Ball Mill: Operating principles, components, Uses

194 questions with answers in BALL MILLING Science topic

Feb 19, 2021 "In a typical synthesis, 0012 mol Li2CO3 (An excess of 20 mol% Li2CO3 was added to compensate for Li loss during processing), 001 mol La2O3, and 004 mol TiO2, were mixed and ball Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applications Some of those applications are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more ball mills Outotec Momentum Group Home A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator FormulaKeywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlWet Ball Mill Sample, 6 steel spheres 2” diameter, water into bucket and rotated 600 revolutions at 60 rpm Potential degradation during hauling, spreading, and construction Sieve Analysis (Gradation) Separation of aggregate particles into different sizes from 13/4” to material passing #40 sieve (002”)FLEX BASE PROPERTIES

Encyclopedia saVRee

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% chargedDec 15, 2015 In this study, a physical ball mill process instead of chemical extraction using toxic chemical agents was applied to remove arsenic (As) from contaminated soil A statistical analysis was carried out to establish the optimal conditions for ball mill processing As a result of the statistical analysis, approximately 70 % of As was removed from the soil at the following conditions: 5 min, 10 A new approach for remediation of Ascontaminated soil