Case

primary crushers iron ore processing pdf

2020-08-05T16:08:39+00:00

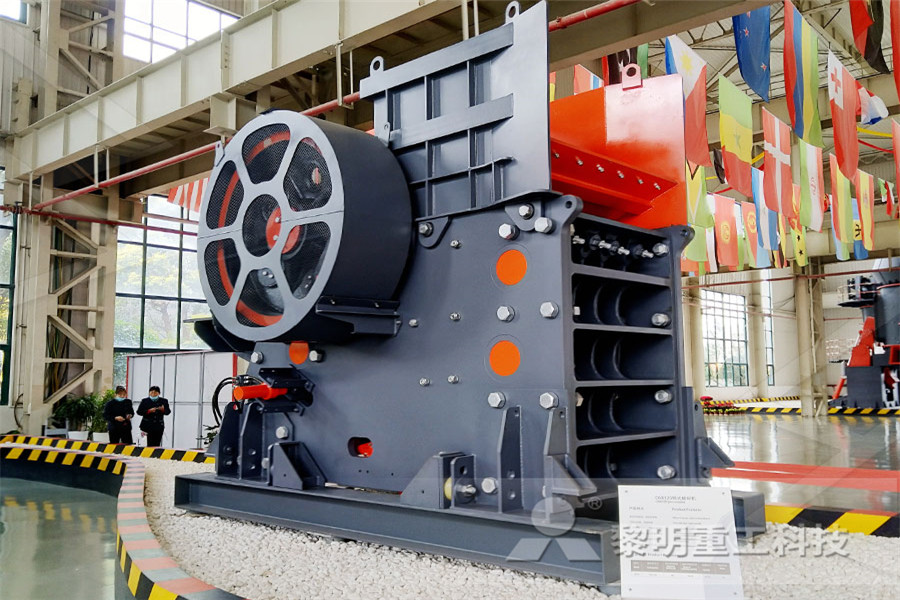

COMMINUTION THEORY AND PLANT PRACTICE

A Jaw Crusher is one of the main types of primary crushers in iron ore processing plant The rectangular or square opening at the top of the jaws (feed opening) designates the size of a jaw crusher For instance, a 24 x 36 jaw crusher has a opening of 24" by 36", a 56 x 56 jaw crusher has a opening of 56" square Primary jawGyratory crushers are the most efficient primary crushers for dealing with blasted hard rock in ore and natural stone mining Due to different crushing chamber designs these machines can either prepare materials for downstream processing with a high crushing ratio, or reduce overburden to a size suitable for belt conveying with a low crushingDesign of a crushing system that improves the crushing –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processingcrusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerationsiron ore prospects for our mining operations Mining Once the ideal site has been chosen, the ore is drilled and blasted Primary Crusher It is then transported to the primary crusher for processing Ore handling plant The crushed ore is then sorted over screens and resized to di˚erent speci˜ications, such as lump and ˜ines products Stacker11335 BHP Commodity Fact Sheets IRON ORE EX9

Mineral dressing (= Orebeneficiation)

– ii Secondary Crushing (intermediate crushing): In this case, ore is crushed from 10 cm to less than 1 –2 cm size; for this purpose jaw, cone or roll crushers are used These secondary crushers consume more power than primary crushers – iii Tertiary Crushing (fine crushing): By tertiary crushers oreCrushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) SIZE REDUCTION BY CRUSHING METHODSProcessing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate A simplified flow diagram of these processing steps is shown in Figure 21Emission Factor Documentation for AP42 Taconite Ore crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing

1123 Taconite Ore Processing

for taconite ore processing is 303023 Table 11231 lists the SCCs for taconite ore processing Taconite is a hard, banded, lowgrade ore, and is the predominant iron ore remaining in the United States Ninetynine percent of the crude iron ore produced in the United States is taconite IfIn Mineral Processing Design and Operations (Second Edition), 2016 Abstract Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large runofmine ore pieces to acceptable sizes Descriptions of secondary and tertiary cone crushers that usually follow gyratory crushers are also given in detailPrimary Crusher an overview ScienceDirect TopicsCivmec delivered the primary crushing and ore processing facility for FMG’s new Eliwana mine and rail project in the Pilbara Our scope was for the full vertical delivery of the facility’s iron ore loading, primary, secondary and tertiary crushing, ore screening and associated conveyor systems, up to no load commissioningEliwana Primary Crushing and Ore Processing Facility Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing BritannicaIn the first (primary) stage, the stone crusher used is a jaw crusher or an impact crusher Jaw crusher is used to break hard textured stones, such as andesite, coral, granite, basalt, and other hard natural stones Impact crushers are used to break rocks with low hardness (soft medium hard ore) which tend to clay, such as limestoneSell Primary Crusher Jaw Crusher DAIHO

Stone Crusher Machine Jaw Crusher DIDAPAT

Jaw Crusher machine is used for processing mining mineral products, such as crushing copper ore, bauxite, arsenic gold ore, aragonite, barite, tin ore, iron ore, alunite, asphalt, manganese, zinc ore, silver ore, basalt and various other rocks Jaw Crusher is a stone crusher that belongs to the primary crusher so that the result of processing Apr 15, 2013 Copper ore mining equipment manufacturer, crushing and grinding machine in mining plant power consumption of copper ore processing plant manganese crusher This entry was posted in Uncategorized Bookmark the permalink copper ore processing plant manufacturers worldcrushersore crushing washing screening ppt – Crusher, crusher prices Kaunisvaara Iron Ore Project (5037 kb) Power point Chp ppt 5479 views Like Topic 3: Ore processing and stone crusher machine in gujarat ppt stone crusher Chp Ppt Iron Ore Crushing Machine Crusher Mills, Cone A Jaw Crusher is one of the main types of primary crushers in iron ore processing plant The rectangular or square opening at the top of the jaws (feed opening) designates the size of a jaw crusher For instance, a 24 x 36 jaw crusher has a opening of 24" by 36", a 56 x 56 jaw crusher has a opening of 56" square Primary jawCOMMINUTION THEORY AND PLANT PRACTICEELIWANA PROJECT PACKAGE 751EWC0017 – CONSTRUCTION OF PRIMARY CRUSHER AND ORE PROCESSING FACILITY SCOPE OF WORKS 751EWC00010000TEAD0001 Eliwana Project: AIP Scope of Work Project Overview: FMG is developing a new Iron Ore mine and associated infrastructure at its Eliwana Site (Eliwana Project) located in the Pilbara region of Western AustraliaPACKAGE 751EWC0017 CONSTRUCTION OF PRIMARY

MINERAL PROCESSING LABORATORY MANUAL VSSUT

To crush the of Ore (iron ore pellets) in a Primary Jaw Crusher (Blake Jaw Crusher), and to determine the average product size by sieving MATERIALS / APPARATUS REQUIRED: 1 Ore (iron pellet) 2 Different sieve screens of ASTM size 3 Black jaw crusher 4 Weight balance 5 –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore ProcessingTechnologies used up to date for processing lowgrade iron ores in Brazil, in particular itabirites, have consisted of three or four stages of crushing followed by ball milling(PDF) Processing of Magnetite Iron Ores–Comparing Grinding A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushingCrusher WikipediaCivmec delivered the primary crushing and ore processing facility for FMG’s new Eliwana mine and rail project in the Pilbara Our scope was for the full vertical delivery of the facility’s iron ore loading, primary, secondary and tertiary crushing, ore screening and associated conveyor systems, up to no load commissioningEliwana Primary Crushing and Ore Processing Facility

Cold test successfully completed on iron ore crushing and

Feb 02, 2021 natural fines processing; and; final stacking and transfer sections The primary crushing section includes a primary gyratory crusher, from which coarse ore is conveyed to a stockpile with a rated throughput capacity of 1,600 t/h Downstream sections from primary crushing comprise major process equipment such as: secondary and tertiary cone Aug 14, 2019 Civmec to deliver primary crushing and ore procesing plant for Fortescue’s Eliwana Posted by Paul Moore on 14th August 2019 Civmec Ltd is to deliver the Primary Crushing and Ore Processing Facility for Fortescue Metals Group’s new Eliwana Mine and Rail project, located approximately 90 km northwest of Tom Price in the Pilbara region of Civmec to deliver primary crushing and ore procesing plant Apr 15, 2013 Copper ore mining equipment manufacturer, crushing and grinding machine in mining plant power consumption of copper ore processing plant manganese crusher This entry was posted in Uncategorized Bookmark the permalink copper ore processing plant manufacturers worldcrushersJaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate JXSC Iron Ore,Ore Processing,Ore Beneficiation,Mining Iron Ore Mining Solution is supported here while Mining Machinery is focusing on Iron Ore Beneficiation and Processing Plant Secondary Crusher Tertiary Crusher »More detailedmining iron ore is a tertiary or a secondary activity

iron ore primary crushing nhahangvuonda

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The common primary crushers are of jaw and gyratory typesget priceHome > Product >primary crushers iron ore processing primary crushers iron ore processing T11:01:15+00:00 MTW Series Heavy Type European Grinding Output size : 160045 mm, the fineness is 0038mm Production capacity : 3545T/H PROCESSED MATERIALS limestone, calcite, barite, dolomite, potassium feldspar, primary crushers iron ore processing