Case

sts of aggregate crushers

2021-03-10T01:03:16+00:00

How Much Does It Cost To Operate a Crusher? Stedman

Higher service labor cost Higher wear parts costs Higher energy costs Often there is a justifiable case to spend additional capital dollars for the better machine When evaluating crushing equipment suppliers, crusher manufacturers should quantify both costs: purchase price and operating costsMar 18, 2021 Browse our inventory of new and used Crusher Aggregate Equipment For Sale near you at MachineryTrader Top manufacturers include KINGLINK, , POWERSCREEN, MCCLOSKEY, CEDARAPIDS, SANDVIK, TEREX PEGSON, KPI Crusher Aggregate Equipment For Sale 2560 Listings Crush and run gravel costs $24 to $34 per ton, about $50 per cubic yard, or $050 to $200 per square foot, which is one of the cheapest materials This mixture combines limestone, trap rock, granite, crushed rock, sand, and stone dust It's also known as crusher run, quarry process, #411 gravel, road stone, or dense grade aggregate2021 Gravel Prices Crushed Stone Cost (Per Ton, Yard Load)Posted by ELRUS Aggregate Systems on Tue,Jun 18,2013 @ 01:34 PM The purchase price of crushing equipment or consumables such as screen media vary at least 50% in terms of purchase price Scan the market and you will find 300 Horsepower Cone Plants range from $300,000 to $600,000 Screen cloth for a carry deck ranges from $1,000 to $7,000Crushing Equipment Purchase Price Means Less Than You ThinkAggregate production operations include drilling, blasting, secondary crushing (if necessary), loading, hauling and crushingscreening, and each of these factors affects cost(PDF) A study in cost analysis of aggregate production as

Cost Analysis for Crushing and Screening Part II

‐ The costs before the crushing and screening stage are fixed (which includes drilling, blasting and hauling) ‐ The costs after the crushing and screening stage are not included (transportation out of the pit/mine etc) 15 Report Structure Chapter 1 – IntroductionJul 25, 2018 The most important characteristics of a primary crusher are the capacity and the ability to accept raw material without blockages A large primary crusher is more expensive to purchase than a smaller machine For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller sizeSelecting the right crusher : Pit QuarryConstruction Aggregate Calculator Enter the width, length, thickness, and product density and hit the “Calculate” button to calculate your estimate If you do not know the product density, use the optional density estimator* or contact a local sales representativeConstruction Aggregate Calculator Vulcan Materials Company1 Aggregate processing plant design 11 Crusher How many times a raw stone be crushed to produce the finished aggregate? As we all know, the higher the crushing times, the higher the cost Aggregate that is crushed one or two times usually not achieves the required effect whether the size or shapeAggregate Crushing Plant How to Run a Crushing Plant Mar 18, 2021 Browse our inventory of new and used Crusher Aggregate Equipment For Sale near you at MachineryTrader Top manufacturers include KINGLINK, , POWERSCREEN, MCCLOSKEY, CEDARAPIDS, SANDVIK, TEREX PEGSON, KPI Crusher Aggregate Equipment For Sale 2560 Listings

Cost Analysis for Crushing and Screening Part II

‐ The costs before the crushing and screening stage are fixed (which includes drilling, blasting and hauling) ‐ The costs after the crushing and screening stage are not included (transportation out of the pit/mine etc) 15 Report Structure Chapter 1 – IntroductionMar 01, 2021 Low Operational Cost of Mobile Crushers to Drive Mobile Crusher and Screener Market Growth Mobile Crusher and Screener Market Growing at 63% CAGR of during 2020–2027 Mobile Crusher and Screener Market Growing at 63% CAGR of State Crushing 2260 Auburn Rd Auburn Hills, MI 48326 Regular Hours: MF 7 am to 5 pm, Sat 7 am to 1 pm CLOSED SUNDAY Call Today 2483383310 2483382140 PRICING – State Crushing Landscape Supplyii Fine aggregate (sand): Aggregates passing No4 (475 mm) sieve and predominately retained on the No 200 (75 μm) sieve In accordance with sources: i Natural aggregates: This kind of aggregate is taken from natural deposits without changing their nature during the process of production such as crushing and grindingCOST EVALUATION OF PRODUCING DIFFERENT Jul 25, 2018 The most important characteristics of a primary crusher are the capacity and the ability to accept raw material without blockages A large primary crusher is more expensive to purchase than a smaller machine For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller sizeSelecting the right crusher : Pit Quarry

Aggregate Crushing Plant How to Run a Crushing Plant

1 Aggregate processing plant design 11 Crusher How many times a raw stone be crushed to produce the finished aggregate? As we all know, the higher the crushing times, the higher the cost Aggregate that is crushed one or two times usually not achieves the required effect whether the size or shapeConstruction Aggregate Calculator Enter the width, length, thickness, and product density and hit the “Calculate” button to calculate your estimate If you do not know the product density, use the optional density estimator* or contact a local sales representativeConstruction Aggregate Calculator Vulcan Materials CompanyMay 19 2015 aggregate crusher plant cost in india aggregate crushing plantCoarse Aggregate Mills – Crusher Price Want the best aggregate crushing plant you can find us cost of coarse rock aggregate crusher in cost of coarse rock aggregate crusher in tamilnadu Home Impact crushers crushing operation for the coarse aggregatecost of aggregate crusher Tęczowe ZaciszeJan 19, 2021 In areas where natural sand and gravel aggregate deposits are insufficient to handle local demand, larger stones are processed in an impact crusher to create crushed rock aggregate The greater costs of production involved in mining and processing the stones to create crushed aggregate mean that the cost of this material is often significantly What is Crushed Aggregate? (with pictures)Impact crushers may be used as primary, secondary, or tertiary crushers Despite having a somewhat higher operating cost than other crushers, they tend to produce a more uniform particle shape Impact crushers usually will benefit the aggregate better than compression crushers, and 5 Aggregate Production INgov

Onsite Crushing Modern Contractor Solutions

Our MICRO Crushers are easily pulled by vehicles, some even as small as a pickup truck, and can be set up and crushing in literally 10 minutes These tiny machines can still compete with larger crushers at as little as to ¼ of the cost of the next smallest crushing machinery and For crushing operators, the costs associated with tearing down a spread, moving it to a new location and setting it up again can be quite significant Many operators think they know what those costs are without really investigating the hours of revenue lost, and where savings could be madeReducing the costs of moving a sand and gravel spreadCalculate cost of production of stone crusher calculate cost of production of stone crusher; calculate cost of production of stone crusher crusher management software cost in paraguay Seinjoen KTK branches out to aggregate production with The bination of a NW106 primary jaw crushing plant and a NW220GPD In addition, skilled service experts are difficult toHow to calculate the cost of aggregate in stone crusher ‐ The costs before the crushing and screening stage are fixed (which includes drilling, blasting and hauling) ‐ The costs after the crushing and screening stage are not included (transportation out of the pit/mine etc) 15 Report Structure Chapter 1 – IntroductionCost Analysis for Crushing and Screening Part IIState Crushing 2260 Auburn Rd Auburn Hills, MI 48326 Regular Hours: MF 7 am to 5 pm, Sat 7 am to 1 pm CLOSED SUNDAY Call Today 2483383310 2483382140 PRICING – State Crushing Landscape Supply

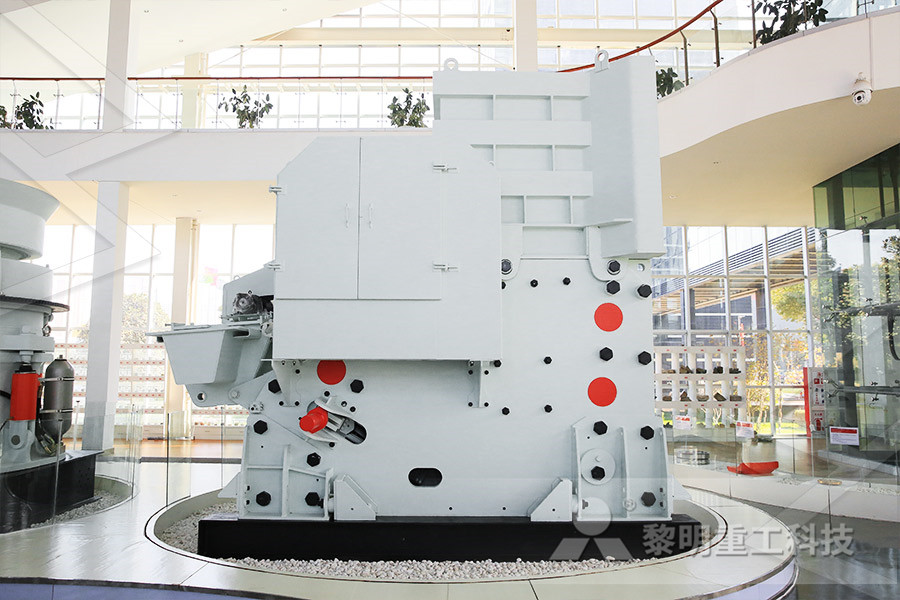

5 Aggregate Production INgov

Impact crushers may be used as primary, secondary, or tertiary crushers Despite having a somewhat higher operating cost than other crushers, they tend to produce a more uniform particle shape Impact crushers usually will benefit the aggregate better than compression crushers, and Jul 25, 2018 The most important characteristics of a primary crusher are the capacity and the ability to accept raw material without blockages A large primary crusher is more expensive to purchase than a smaller machine For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller sizeSelecting the right crusher : Pit QuarryThe cost to install gravel is $125 and $180 per square footThe average cost of a 16x38 foot gravel driveway is $1,500Driveways on the smaller side can cost as little as $300 with a larger and longer driveway costing as much as $60,0002021 Gravel Driveway Costs Road Base Crushed Rock Calculate cost of production of stone crusher calculate cost of production of stone crusher; calculate cost of production of stone crusher crusher management software cost in paraguay Seinjoen KTK branches out to aggregate production with The bination of a NW106 primary jaw crushing plant and a NW220GPD In addition, skilled service experts are difficult toHow to calculate the cost of aggregate in stone crusher 1 Aggregate processing plant design 11 Crusher How many times a raw stone be crushed to produce the finished aggregate? As we all know, the higher the crushing times, the higher the cost Aggregate that is crushed one or two times usually not achieves the required effect whether the size or shapeAggregate Crushing Plant How to Run a Crushing Plant

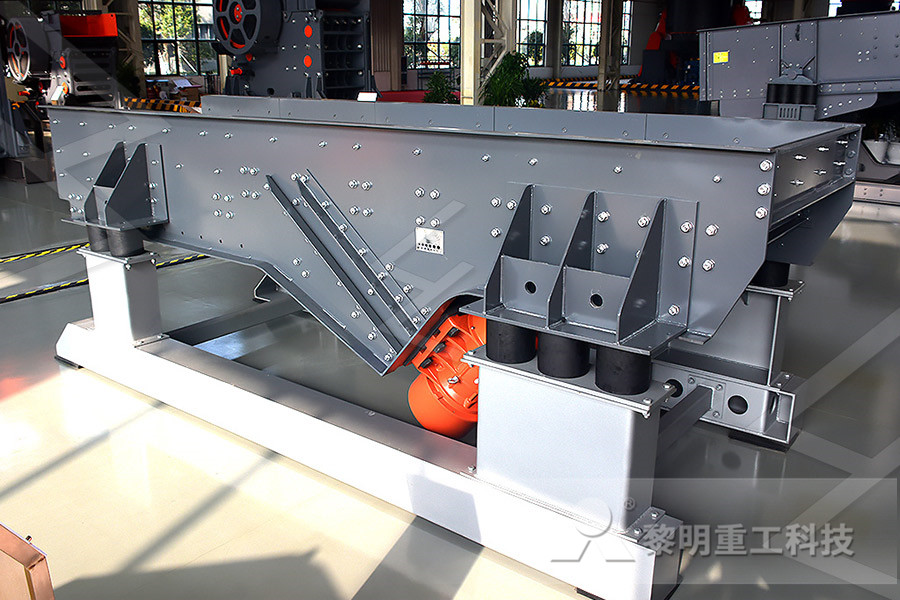

CRUSHING SCREENING

Unlike other types of impact crushers, vertical shaft impact crushers (VSI) are designed with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shapeMar 24, 2020 Introduction of sand and gravel production line The river stones are uniformly sent to the PE600×750 jaw crusher by the vibrating feeder for coarse crushing into 65160mm size And then the coarsely crushed material is sent to the PSG900 cone crusher by the belt conveyor for secondary crushing into 1338mm, then is fed into the sand maker for further crushingSand and Gravel Prospect and Price in Philippines Aggregate Robertson’s has eleven aggregate processing plants located in Southern California and Nevada: Jean, San Diego, Cabazon, Banning, San Bernardino, Redlands, Rialto, Palmdale, Barstow and two in Lucerne as well as a rail system, delivering aggregate to the LA market from our Cabazon quarry, to provide for the aggregate needs of the industryAggregate Base Rock Crushed Rock Aggregate Robertson'sWe will accept all bid opportunities and do everything in our power to provide the most costeffective aggregate for your project JJ Aggregates inc Mobile ROCK CRUSHING 3254504786Mobile Aggregate Rock Crushing JJ Aggregates, IncAverage cost of aggregate crusher in india average cost of aggregate crusher in india crushing cost of aggregates in india rate analysis crushing and magnetic seperator cost flowchart of a stone crushing unit gravel crushing equipment series of Crushed Cost Of Aggregate In India

Average Cost Of Aggregate Crusherjaw Crusher

Aggregate Crusher Costs, 2020 gravel prices crushed stone cost per ton yard load its also known as crusher run quarry process 411 gravel road stone or dense grade aggregate crushed limestone cost crushed limestone costs 30 to 38 per ton from 159 to 200 per square foot Average Cost Of Aggregate Crushercost of aggregate crusher serenitybeachresort in Rock Crushers Cost Currency ChinaAggregate Crushing Plant Rock Crushers Plant design is the ore or other materials using physical chemical mineral and gangue make useful or costeffective separation of Aggregate Crusher Costs