Case

working of gritt seperator for al mill in cement plant

2023-09-29T10:09:49+00:00

how grit separator working in cement plant « Mining

Jun 11, 2013 > Mining Equipment > how grit separator working in cement plant; Print how grit separator working in cement plant Posted at:June 11, 2013[ 49 3539 Ratings] FL replaces coal mill separator DISAB Engineered Vacuum Systems Marble in Greenland, cement in Jamaica, Black Metallurgy in Russia, blasting sand in Korea Thanks to its rugged construction the systems from DISAB el PES 301/90 and two preseparator BEPSL 30 SK 30, a pipeline and painting companies for the blast grit particle boards, in malt houses, fodder, mill, floor andworking of grit separetor in cement millworking of separator raw mill in cement factory The is the professional mining equipments manufacturer in the world, located in China,India, along with other Asian marketplaces to develop and develop, now we Separator Working Procedure In Raw MillCoal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installationsCoal Mills for Cement Plants LoescheCoal Mill Separator Guide Vanes, 500 dia X 5m long pipe (with cladding on ID/OD), coal mill feed screw, Rotor cone for grit separator earplates for hammer crusher wear guards and bracket for seal air pipe, cone for fine separator Cone Coal mill separator, Louver for Grit Separator, Rotor of sepax separator, feed screw for Coal Mill: 28Duraweld Metsys Pvt Ltd

Cement mill seperator Page 1 of 1

We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down) The rotation of the seperator is between 43 to 170 and it work always in 115120 RPM and the blaine is 29003100 in opcNew highefficiency separator for phoenix cement cement limechristian pfeiffer, went into operation at phoenix in 1969as the amount of available space in the former mill building of cement mill 2 was veryconveying equipment for separator feed, finished product and grit Cement Mill Separator EfficiencyJan 19, 2014 The raw is then fed to the coal mill VRM via weigh feeder, drag chain and screw conveyer Important Parameters Of Coal: • Residue on 90 micron=1820% • Residue on 212micron=041% • Moisture =15% • Volatile Matter =2030% • Ash content =2832% Coal Mill:Coal Mill is an important integral part of cement plantcement plant report SlideShareTo summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists in the main fuelCoal Mill an overview ScienceDirect TopicsThe cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cementraw mix, shorten the length of rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, which promote the Preheater In Cement Plant, Cyclone Preheater, Cement

Separator SEPCON Engineering (India) Pvt Ltd

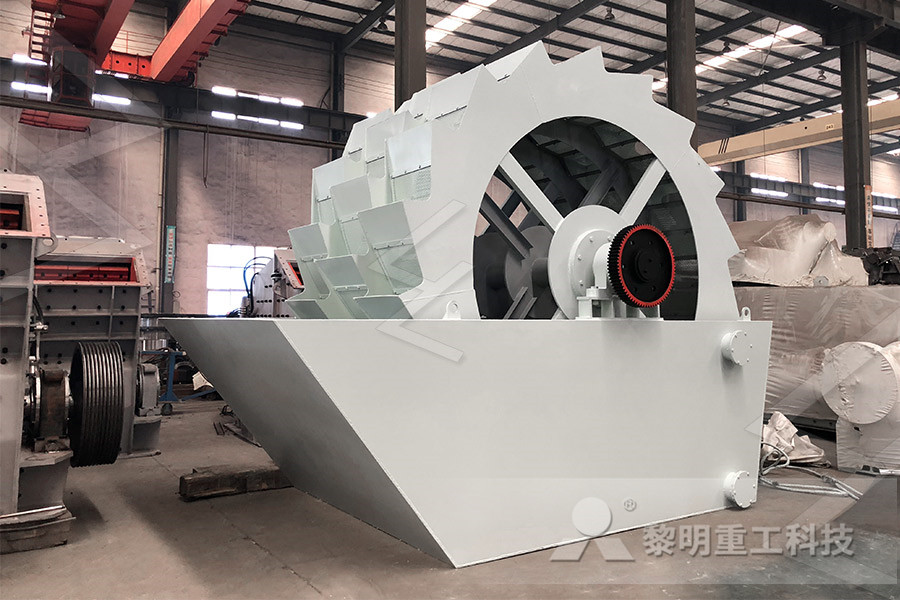

Cement Plant Machinery Manufacturers While the mill is performing the grinding work, the Separator removes the finer particles from the mill discharge and prevents them from being over ground, Grit / Static Air Separator: Grit Separator or Static Separator have no rotary parts to do the separation The separation is done with the help Jan 20, 2016 The raw coal from the stockyard is crushed in a hammer crusher and fed to the coal mill The coal mill is a vertical roller mill, in which the coal particles are collected in a bag filter through a grit separator The required size of coal is 80% of 90 μm and less than 2% of 212 μm (Atmaca and Yumrutaş, 2014) Hot air generated in a coal Analysis of material flow and consumption in cement The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution for cement plants Equipped with the highefficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the requiredATOX coal mill Gravity separation is the separation of two or more minerals of different specific gravity by their relative movement in response to the force of gravity and one or more other forces (such as centrifugal, drag or buoyant forces) The resistance to motion, known as drag force, by a medium such as heavy media, water or even air, is one such force gravity density separators for mineralsDSK Dynamic Coal Separator For damp materials The dynamic coal separator (DSK) is used in cases where materials with high feed moisture are ground The vertical position of its centrallypositioned feeding chute prevents the damp material from sticking The material to be ground thus goes directly to the grinding table of the vertical millprefix Overview of our separators Christian Pfeiffer

(PDF) Analysis of material flow and consumption in cement

The separator and mill dust collectors are the primary waste gas discharge points in the fi nal grinding stage, with dis charges of approximately 32972 t/h and 77 58 t/h, sharing 5694%Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used Rotational effects and gravity are used to separate mixtures of solids and fluids The method can also be used to separate fine droplets of Cyclonic separation WikipediaThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw millRaw Mill In Cement Plant,Cement Making PlantThere are a total of 4 Ball Mills for the cement grinding process The Cement Mills utilize Roller Press as pregrinders with additional Grit Separator for line 2 The total maximum grinding capacity is 72 million tons of cement per year Packing and Loading There are two packing lines in Pukrang Plant Ready to be shipped cement in bulk is Asia Cement Plc Asia CementCement Mill Grit Separator Grit separator in cement plant wiki cement mill grit separator, The coal mill can be an air swept ball mill or vertical roller mill where the coal particles Chat With Sales Cement Mill Ball Mill Dynamics Cement Mill Ball Mill Corp finish mills have static grit separators on the mill compartment designs for Cement Mill Dynamic Separator lebenstrauminbalancede

EnergyEfficient Technologies in Cement Grinding IntechOpen

Oct 23, 2015 Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production of composite cements has been Christmas special for mining machines,We have cement mill separator gap,• The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator During the inspection mill and separator internal condition found in good condition and no coating on internals material accumulation observed However in Chamber I at a distance of 2 to 4cement mill separator gap TSURIAI Heavy MachineryTypes of coal pulverizers Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rodsPulverizer WikipediaVertical mills Flexible mills with integrated separator The vertical mill enables high energy economy, and convinces with low specific wear values Drying of the feed material, grinding, separating, and material transport take place inside the mill It is thus especially well suited for grinding products with high proportions of wet componentsOverview of our mills Christian PfeifferCement Plant Machinery Manufacturers While the mill is performing the grinding work, the Separator removes the finer particles from the mill discharge and prevents them from being over ground, Grit / Static Air Separator: Grit Separator or Static Separator have no rotary parts to do the separation The separation is done with the help Separator SEPCON Engineering (India) Pvt Ltd

Analysis of material flow and consumption in cement

Jan 20, 2016 The raw coal from the stockyard is crushed in a hammer crusher and fed to the coal mill The coal mill is a vertical roller mill, in which the coal particles are collected in a bag filter through a grit separator The required size of coal is 80% of 90 μm and less than 2% of 212 μm (Atmaca and Yumrutaş, 2014) Hot air generated in a coal The separator and mill dust collectors are the primary waste gas discharge points in the fi nal grinding stage, with dis charges of approximately 32972 t/h and 77 58 t/h, sharing 5694%(PDF) Analysis of material flow and consumption in cement DSK Dynamic Coal Separator For damp materials The dynamic coal separator (DSK) is used in cases where materials with high feed moisture are ground The vertical position of its centrallypositioned feeding chute prevents the damp material from sticking The material to be ground thus goes directly to the grinding table of the vertical millprefix Overview of our separators Christian PfeifferThis paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement raw millRaw Mill In Cement Plant,Cement Making PlantThere are a total of 4 Ball Mills for the cement grinding process The Cement Mills utilize Roller Press as pregrinders with additional Grit Separator for line 2 The total maximum grinding capacity is 72 million tons of cement per year Packing and Loading There are two packing lines in Pukrang Plant Ready to be shipped cement in bulk is Asia Cement Plc Asia Cement

Cyclonic separation Wikipedia

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used Rotational effects and gravity are used to separate mixtures of solids and fluids The method can also be used to separate fine droplets of Types of coal pulverizers Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rodsPulverizer WikipediaChristmas special for mining machines,We have cement mill separator gap,• The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator During the inspection mill and separator internal condition found in good condition and no coating on internals material accumulation observed However in Chamber I at a distance of 2 to 4cement mill separator gap TSURIAI Heavy MachineryAug 30, 2012 Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mixCement Manufacturing Process Phases Flow Chart this are deployed in Klingenberg, Europe’s first coal dustfired largescale power plant in Berlin for coal grinding with a raw coal rate of approx 12 t/h 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw materialFOR CEMENT RAW MATERIAL Plant engineering solutions

Cement Plant Quality Control insmart systems

Cement Plant Quality Control Turnkey Projects Robotic Sample Preparation Labs Bond’s Work Index Ball Mills Planetary Micro Milling – PBM Compaction Insmart 40 Ton Hydraulic Press Turbo Mixers Coal Surface Moisture Analyzers Falling Stream Sample Dividers for: Location 5234/1/1, HP Road, Moosapet, Hyderabad Vertical mills Flexible mills with integrated separator The vertical mill enables high energy economy, and convinces with low specific wear values Drying of the feed material, grinding, separating, and material transport take place inside the mill It is thus especially well suited for grinding products with high proportions of wet componentsOverview of our mills Christian PfeifferThe ATOX® Coal Mill handles feed materials with less than one percent moisture and up to 25 percent moisture, where abrasiveness and stickiness is not an issue for grinding Longlasting durability The materials used to produce the ATOX® Coal Mill’s segmented wear Longlasting coal mill for efficient grinding