Case

gyratory crusher operating weight

2020-05-27T17:05:19+00:00

Industrial Solutions Gyratory crushers

gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of crusher Spider 2) Heaviest weight Bottom shell 3) Main shaft 4) Eccentric bushing Gyratory Crusher delivers The SG 1200 features a large stroke, a spherical plain spider bearing, a constant feed opening crushing chamber and a large product discharge area MOTION MAXIMUM POWER APPROXIMATE CRUSHER THROUGHPUT AT LISTED (mm) CSS (mm) (kW) 45mm 48mm 50mm 54mm 57mm 60mm 64mm 24 185 345 355 365 370 375 380 385 Minerals Processing Systems SG 1200 Gyratory Crusher2 GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile tus W Gates in 1881 This fint crusher was used by the Buffalo Cement Co At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done2 GYRATORY CRUSHERSJan 01, 2016 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10% The crushing action in gyratory crushers is regarded as rings or ‘helics’ (spirals) of feed down through the crusher of which a single section may be regarded as similar to the jaw crusherGyratory and Cone Crusher ScienceDirectIn Mineral Processing Design and Operations (Second Edition), 2016 51 Introduction Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks Gyratory Crusher an overview ScienceDirect Topics

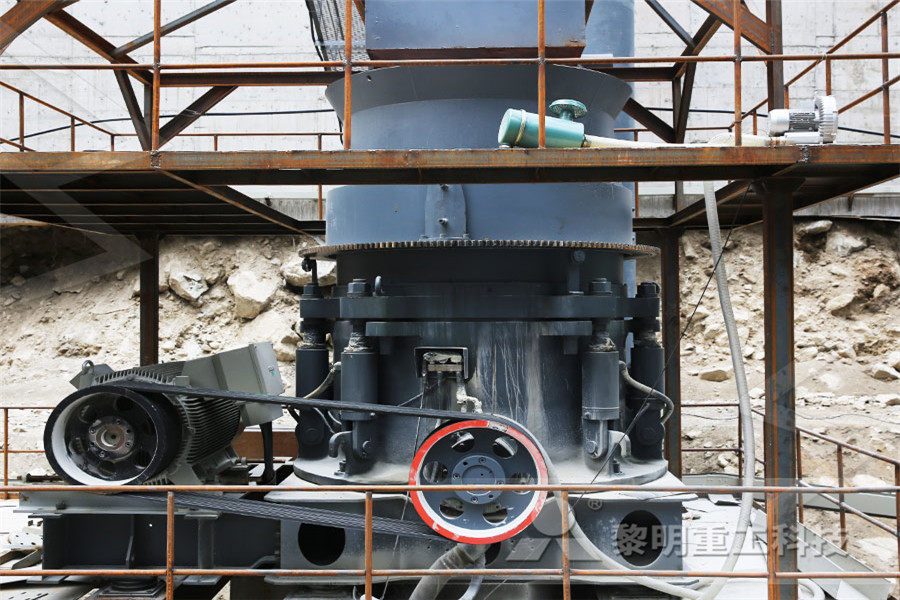

Gyratory Crushers Mineral Processing Metallurgy

Metallurgical ContentGyratory CrushersGyratory Crusher Capacity TablesSmall Gyratory Crusher Capacity ChartCrusher DriveGyratory CrusherEccentricity Adjustable to Capacity Demands ADVANTAGES OF BOTTOM DISCHARGELOW OPERATING COSTS VERTICAL ADJUSTMENTSMETHODS OF VERTICAL ADJUSTMENTGyratory Crusher Spider Operating weight: 56t – Crusher opening length: 132m – Crusher opening width: 09m – Plant type: RM – Crusher type: PB – Drive: E AntiTheftProtection and usage time! Installed in a few seconds usable for nearly every device on the construction site Lokotrack LT 1213 SE Specifications Technical Data Gyratory crusher works as the primary crusher for the ore which are hard tough to break Having high reduction ratio ie RR= F80/P80 Nearly about 910 PThe Gyratory Crusher Operation YouTubeStandard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to safety a Safer, smarter, more powerful crushing Standard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to Safer, smarter, more powerful crushing

Jaw Crusher an overview ScienceDirect Topics

Capacities of gyratory crushers of different sizes and operation variables are published by various manufacturers The suppliers have their own specifications which should be consulted As a typical example, gyratory crusher capacities of some crushers are shown in Tables 55 and 56The most common types of crushers are the gyratory crusher, the jaw crusher and the cone crusher The primary operating costs of a crusher are parts and labour for maintenance, which can vary approximately twice as much as the power for the motor A good starting point for water addition is 1% of the weight of the material to be crushed Crushers QueensMineDesignWikiModel 20002017 (Other machines by ) Rate this machine now Operating weight: 40t – Crusher opening length: 132m – Crusher opening width: 09m – Transport length: 147m – Transport width: 3m – Transport height: 34m LT 1213 Specifications Technical Data Gyratory crusher operating mechanism The arrangement of the ball and socket joint therefore is such that the weight of the bearing sleeve 44 together with the sets of roller bearings 42 and 46 are all carried by the ball sleeve 40 which in turn is supported on the socket surface of the eccentric sleeve 30 The sleeve member 38 may be moved Gyratory crusher operating mechanism Kennedy, Joseph EGyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products This method is Gyratory equipment Wikipedia

weight specifications of the cone crusher

A unique roller bearing design reduces operating expenses by up to 50 percent, while improving production and energy efficiency compared to bushing crushers It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size ; but The objective of this research was to develop a mathematical model for gyratory crushers to help in the prediction of energy consumption and to analyze dominant parameters that affect this energy (PDF) A Gyratory Crusher Model and Impact Parameters They have been a leading supplier of crushers under the Traylor brand name since 1905 As a world class supplier of crushing equipment for the mining, cement and aggregate industries, we offer crushing products and technology with proven names like FullerTraylor, ABON and Buffalo and and are supported by one of the world’s largest crusher compression crusher technology for miningNov 28, 2018 Maintain crusher backing to ensure proper vibration and impact protection Keep breathers clean Make sure the toggle area is clean, especially prior to any adjustments Wash out seats and plates daily Gyratory Crushers Check spider bushing clearance monthly, every 500 hours, or with every mantle change Whichever comes firstTips for Crusher Maintenance ThomasnetPGC 1500 : Feed opening: 1500 mm: Nominal Discharge: 160200 mm: Capacity (CuM/hr) 1450: Main Drive Motor: 400 kw : Weight of Crusher : 428 T (with out electrics)Heavy Engineering Corporation Limited, Ranchi, India

Krupp crusher Krupp crusher parts Krupp crusher spare

The ThyssenKrupp Gyratory cone crusher has 7 types: KB 5467, BK 5467, KB 5475, BK 6375, KB 6375, KB 6389, KB 63114 The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience of ThyssenKrupp Changing mining and processing methods demand (besides new materials and design methods) a continual development of the Gyratory and jaw type gyratory crushers are more broadly an integral part of semimobile and stationary processing plants used for primary crushing of bulk materials in ore mines and the natural thyssenkrupp extends gyratory crusher winning streak Dec 28, 2015 This long operating life can be attributed to the robust design that still utilizes to this day The basic concept behind the Gyratory Crusher remains the same as it did during its inception, but the machine is entirely updated to address today’s advanced technology, safety concerns, and operation schedules FullerTraylor gyratory crushers Mining Pedia Capacities of gyratory crushers of different sizes and operation variables are published by various manufacturers The suppliers have their own specifications which should be consulted As a typical example, gyratory crusher capacities of some crushers are shown in Tables 55 and 56Jaw Crusher an overview ScienceDirect TopicsCITICHIC PXZ Gyratory Crushers Series II CITICHIC PXZ Series II Primary Gyratory Crushers offer a range of crusher sizes to suit the most demanding of applications in some of the world’s largest mining projects With feed sizes up to 1200mm and capacities of 8000TPH Combined with high speed (600rpm) and a range of eccentricGyratory CRUSHERS CITIC HIC

Heavy Engineering Corporation Limited, Ranchi, India

PGC 1500 : Feed opening: 1500 mm: Nominal Discharge: 160200 mm: Capacity (CuM/hr) 1450: Main Drive Motor: 400 kw : Weight of Crusher : 428 T (with out electrics)A unique roller bearing design reduces operating expenses by up to 50 percent, while improving production and energy efficiency compared to bushing crushers It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size ; but weight specifications of the cone crusherThe objective of this research was to develop a mathematical model for gyratory crushers to help in the prediction of energy consumption and to analyze dominant parameters that affect this energy (PDF) A Gyratory Crusher Model and Impact Parameters Gyratory crusher operating mechanism The arrangement of the ball and socket joint therefore is such that the weight of the bearing sleeve 44 together with the sets of roller bearings 42 and 46 are all carried by the ball sleeve 40 which in turn is supported on the socket surface of the eccentric sleeve 30 The sleeve member 38 may be moved Gyratory crusher operating mechanism Kennedy, Joseph EFeb 12, 2020 Gyratory and jaw type gyratory crushers are more broadly an integral part of semimobile and stationary processing plants used for primary crushing of bulk materials in thyssenkrupp extends gyratory crusher winning streak

compression crusher technology for mining

They have been a leading supplier of crushers under the Traylor brand name since 1905 As a world class supplier of crushing equipment for the mining, cement and aggregate industries, we offer crushing products and technology with proven names like FullerTraylor, ABON and Buffalo and and are supported by one of the world’s largest crusher Apr 01, 2015 Fig 9 shows the particle flow in the gyratory crusher operating in a batch arrangement after a full load is dumped into the crusher Fig 9 a shows an oblique view from above with a section of the crusher not shown so that the particles inside can be seenSimulation of particle flows and breakage in crushers Nov 28, 2018 Maintain crusher backing to ensure proper vibration and impact protection Keep breathers clean Make sure the toggle area is clean, especially prior to any adjustments Wash out seats and plates daily Gyratory Crushers Check spider bushing clearance monthly, every 500 hours, or with every mantle change Whichever comes firstTips for Crusher Maintenance ThomasnetDec 28, 2015 This long operating life can be attributed to the robust design that still utilizes to this day The basic concept behind the Gyratory Crusher remains the same as it did during its inception, but the machine is entirely updated to address today’s advanced technology, safety concerns, and operation schedules FullerTraylor gyratory crushers Mining Pedia Model 20052011 (Other machines by ) Rate this machine now Operating weight: 66t – Crusher opening length: 1375m – Crusher opening width: 076m – Transport length: 174m – Transport width: 35m – Transport height: 38m LT 3054 Specifications Technical Data

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Weight Of Primary Crusher For Coal Gyratory crusher 60 89 operating weight gyratory crusher 60 89 operating weight small crusher operating in batches of 5 togyratory crusher ise bottom of the crusherlls rotate at between 60300 rotationmin andpects of underground primary crusher plant designt price and support online crusher gyratory 60" x 89weight of allischalmers primary gyratory crusher