Case

electrostatic separation equipment

2022-08-11T05:08:47+00:00

Electrostatic Separation Equipment Mineral Technologies

Plate Screen Electrostatic Separators Designed for separation of titaniferous mineral sands, hard rock ilmenite and rutile, cassiterite, tantalite, wolframite, iron ore, plastics from metals in waste recycling system and PVC from other plasticsThis electrostatic separation device has also been successful at beneficiating other inorganic materials, including minerals such as calcium carbonate, talc, barite and others The STET separator has also been successfully applied to processing gricultural materials such as oilseed meals and pulses, and animal meals and rendering productsMinerals Separation Equipment Electrostatic Belt SeparatorElectrostatic separation equipment is simple and easy to maintain and operate It is also conducive to environmental protection It is an important part of circuit board recycling equipment and copper wire separator as wellHigh Sperate Rate Electrostatic Separation EquipmentElectrostatic Separation Procedure Separation of minerals utilizing differences in their electrical properties may be carried out using an electrostatic separator It will separate electrical conductors (minerals such as cassiterite and rutile) from those that are electrical nonconductors (minerals such as zircon and siderite)Electrostatic Separator 911MetallurgistElectrostatic separators provide the only existing separation method for a number of mineral and recycling applications The new Bunting design has been developed in conjunction with technical experts in mineral processing and recycling technology The Bunting design is the culmination of several years of technological development and researchElectroStatic Separators Bunting Redditch

Magnetic and Electrostatic Separation SGS

Eddy–current electrostatic separators; Magnetic separation is a wellestablished separation technique and has become increasingly popular as new equipment on the market enhances the range of separations possible It is an attractive process choice because of low capital and operating costs and the lack of chemicals to cause environmental NAPCO Separation Equipments, Inc (NAPCO)offers the best available technology for controlling particulate matter emissions With over + 100 electrostatic precipitator installations throughout the Globe, our twentyfirst century technology is unique and many Electrostatic Precipitator by NAPCO Separation air ELECTROSTATIC SEPARATION Hamos is a German manufacturer of electrostatic separation technology for the recycling industry Through years of research and development, hamos has positioned itself as one of the leaders of the materials separation industryELECTROSTATIC SEPARATION – eFACTOR3Founded in 1989, ST capitalized on proprietary technology to develop a unique, triboelectrostatic belt separator Since then, the compact and easy to permit separator has beneficiated fine materials within several industriesST Equipment Technology (STET) Processing Equipment An electrostatic dehydrator – also referred to as an electrostatic treater, electrostatic separator, or electrostatic coalescer – uses electricity to remove dispersed water droplets from oil Crude oil flowing from upstream production separators is partially degassed before entering a dehydratorElectrostatic Separation VME

Electrostatic Separators Eriez Lab Equipment

High Tension Electrostatic Separator: 533: 14" diameter by 6" wide polished stainless steel rotor with one screen set and one plate set interchangeables with rotor, and Hamos Electrostatic Separation Equipment Recycling and Separation Technology complete systems for recycling and separation of plastic mixtures, cable scrap, electronic scrap ( black plastic ), composite materials and minerals as well as for separation Hamos Electrostatic Separation Equipment Copper RecoveryJan 13, 2020 the electrostatic separator Structural composition of electrostatic separation equipment It consists of a feed inlet, negative pole, high voltage electric field, metal discharge What is an electrostatic separator? Shuliy MachineryEddy–current electrostatic separators; Magnetic separation is a wellestablished separation technique and has become increasingly popular as new equipment on the market enhances the range of Magnetic and Electrostatic Separation SGSElectrostatic separator Uses:For separation of metal and nonmetal, Adopts high voltage electrostatic processing principle ,separating the metal and nonmetal materials according to their different Electrostatic Separator SUNY GROUP

ELECTROSTATIC SEPARATION – eFACTOR3

Hamos not only supplies electrostatic separation technology but also material handling, transport and packaging modules for the fully automated operation of a threeshift system This includes plant Finally, he ordered our electrostatic plastic sorting equipment on the spot Photographs with customers After equipment was put into use, the customer not only express his sincere thanks to Haibao but ElectrostaticPlasticSeparatorElectrostatic separation equipment Electrostatic separators utilise the conductive properties of particles to separate materials The minerals engineering laboratory at CSM is equipped with a Carpco hightension electrostatic separator which allows for the separation Electrostatic separation Camborne School of Mines Other equipment used historically includes the hutch, a trough used with some oredressing machines and the keeve or kiekkkve, a large tub used for differential settlement Unit operations Mineral Electrostatic separationMineral processing WikipediaJul 07, 2015 Dry electrostatic separators can provide economical separation of even the smallest and finest residual copper particles from cable scrap Wet separation methods, such as socalled “water Charged for separation Recycling Today

What is Electrostatic Separation? (with pictures)

Feb 05, 2021 Electrostatic separation is a process that uses electrostatic charges to separate crushed particles of material An industrial process used to separate large amounts of material particles, electrostatic Electrostatic separator is a device for separating particles by mass in a low energy charged beam And electrostatic separation is a process that uses electrostatic charges to separate crushed particles of material Generally, electrostatic Electrostatic Separator manufacturerFactory directly An electrostatic separator is a device for separating particles by mass in a low energy charged beam An example is the electrostatic precipitator used in coalfired power plants to treat exhaust gas, removing small particles that cause air pollution Electrostatic separation is a process that uses electrostatic Electrostatic separator WikipediaElectrostatic separation Equipment Generally two types of equipment are used for separation These are as follows: 1 Drum type electrostatic separation unit This equipment consists of a rotating VIII ELECTROSTATIC SEPERATION EPrintsHigh Tension Electrostatic Separator: 533: 14" diameter by 6" wide polished stainless steel rotor with one screen set and one plate set interchangeables with rotor, and ships complete with controls in a NEMA 12 enclosure $70,04900 USD: AddElectrostatic Separators Eriez Lab Equipment

Hamos Electrostatic Separation Equipment Copper Recovery

Hamos Recycling and Separation Technology is a leading producer of electrostatic separators and complete systems for recycling and separation of plastic mixtures, cable scrap, electronic scrap ( black plastic ), composite materials and minerals as well as for separation of metals and impurities from plastics, food and moreEddy–current electrostatic separators; Magnetic separation is a wellestablished separation technique and has become increasingly popular as new equipment on the market enhances the range of separations possible It is an attractive process choice because of low capital and operating costs and the lack of chemicals to cause environmental Magnetic and Electrostatic Separation SGSAn electrostatic separator is a device for separating particles by mass in a low energy charged beam An example is the electrostatic precipitator used in coalfired power plants to treat exhaust gas, removing small particles that cause air pollution Electrostatic separation is a process that uses electrostatic charges to separate crushed particles of materialElectrostatic separator WikipediaHamos not only supplies electrostatic separation technology but also material handling, transport and packaging modules for the fully automated operation of a threeshift system This includes plant building for certain applications such as ewaste (hamos KRS) or postconsumer PVC windows and window profiles (hamos WRS)ELECTROSTATIC SEPARATION – eFACTOR3Electrostatic separation Equipment Generally two types of equipment are used for separation These are as follows: 1 Drum type electrostatic separation unit This equipment consists of a rotating drum made of mild steel or some other conducting material, which is earthed through its support bearings as shown below in the Figure 8VIII ELECTROSTATIC SEPERATION EPrints

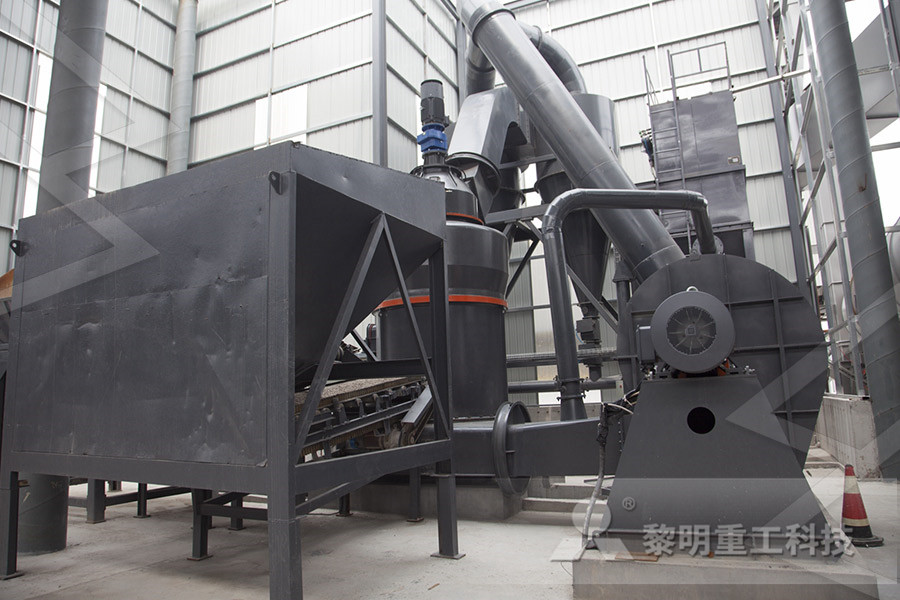

The latest design of electrostatic separation equipment

The latest design of electrostatic separation equipment The latest design of electrostatic separation equipmentElectrostatic separation Electrostatic separation techniques exploit the electrical conductivity differences of particles after charging and the appearance of positive or negative charges on their surface The method of charging varies depending on the equipment and the application A system of attraction or repulsion proportional to this charge enables their separationElectrostatic separation CTPJul 07, 2015 Dry electrostatic separators can provide economical separation of even the smallest and finest residual copper particles from cable scrap Wet separation methods, such as socalled “water tables,” require further processing of wet plastics, which may not be economical in light of the additional drying time requiredCharged for separation Recycling TodayPowder processing operations can generate vast quantities of electrostatic charge via the movement of powder The standard method of charging on powder processing operations is due to triboelectrification, which is basically the contact and separation of the powder with processing equipment, the powder itself, or other factors that can cause charging, like surface contaminantsHow to Eliminate Electrostatic Charging of Powder Electrostatic Metal/Plastic Separator; Two separation drums working in parallel in the first stage; Two additional drum in the second stage to repass the mixed and nonconductive fraction coming from the first stage (important to get a high metal recovery and high plastic purity) Drum length: 4x 1500 mmUSED EQUIPMENT – eFACTOR3

Electrostatic Separator SUNY GROUP

Electrostatic separator Uses:For separation of metal and nonmetal, Adopts high voltage electrostatic processing principle ,separating the metal and nonmetal materials according to their different conductivity Our company developed the enElectrostatic separation equipment Electrostatic separators utilise the conductive properties of particles to separate materials The minerals engineering laboratory at CSM is equipped with a Carpco hightension electrostatic separator which allows for the separation of conductive materials such as cassiterite (tin ore) from insulators such as garnetElectrostatic separation Camborne School of Mines Electrostatic separation equipment adopts automatic voltage regulating device specially that ensures the high voltage power is always stable Hence, the influence of humidity and electricity peak on machine is greatly reduced It is easy to operate, good flexibility, the system safe and stable operation And it possesses the automatic discharge Electrostatic Separator of Plastic/Metal/Mineral for Recycling