Case

crushers jaw primary

2020-10-18T05:10:01+00:00

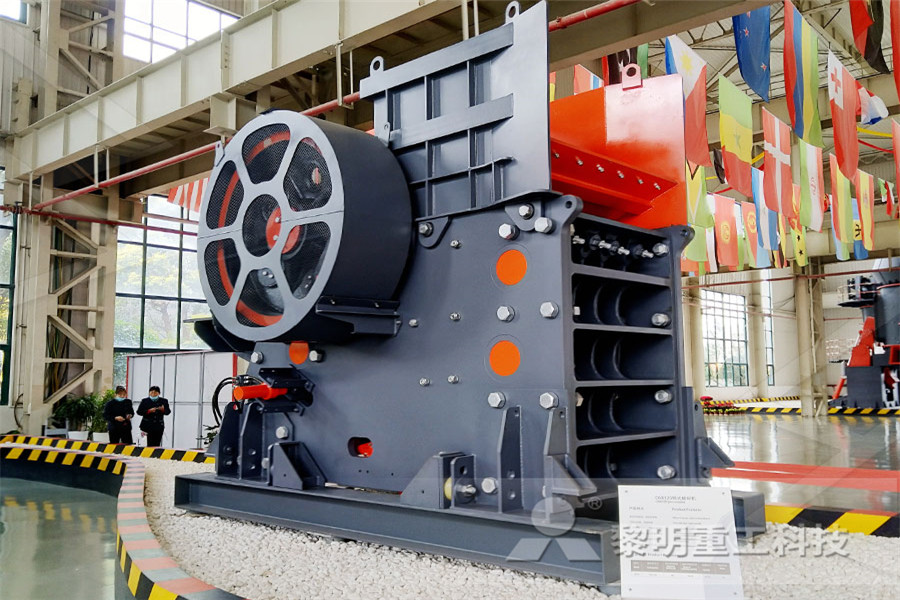

Primary Crushing Stations Primary Plants

’s range of large model jaws includes a 5062, 4248, and 3650 to suit your particular heavy duty, high volume primary crushing application Compare a jaw with any other jaw on the market Immediately you’ll see the shaft and other components are larger, the frame much heavierIn short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate JXSC Trio ® CT series jaw crushers are robust machines Their rugged construction, combined with innovative features, make the Trio ® CT series jaw crusher the clear choice for primary applicationsJaw Crusher Trio® CT Series Primary Weir18 rows The Jaw crusher is used as Primary and Secondary crushers for crushing all kinds of Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers The ® Premiertrak range of highperformance primary jaw crushing plants are designed for operators in quarrying, demolition, recycling, and mining applications The range includes the Premiertrak 330 which boasts a twopiece grizzly feeder allowing better material flow towards the chamberJaw Crushers

Jaw Crushers Rock Crushers Aggregate Crusher

Primary Crushing Stations Our Jaw Crushers Feature: Oversized Shaft, Dynamically Balanced Flywheels All heavyduty jaw crushers feature an oversized, heat treated shaft forged of special alloy to provide an exceptionally large eccentric throwPrimary Jaw Crusher The HyproCrush STJ Primary Jaw Crusher series is a engineered product manufactured to international standard, designed to provide maximum production and performance, thus yielding high outputs with reliability and economical running costsPrimary Jaw Crushers Moore Watson LtdJaw crushers are mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industriesWhat is a Jaw Crusher? TelsmithPrimary Crushing This is the first stage of the crushing process In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm Generally, this value is between 18 and 24 degrees in primary jaw crushers, and between 22 and 28 degrees in secondary crushersWhat is a Jaw Crusher? – MEKA Crushing EquipmentJaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle Jaw Crushers Parker Plant

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing applications of hard abrasive rock or recycling material It is suitable for large and small stationary installations or track and mobile units The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality machined Primary Jaw Crushers Moore Watson LtdLEADER IN PRIMARY JAW CRUSHERS The jaw crusher is one of the most indispensable and preferred machines because of its performance and durability Depending on plant layout, jaw Crusher can be produced on wheels, skidmounted or fixed to the concrete foundationsJaw Crushers MEKA Crushing Screening PlantsMar 10, 2021 Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers:::The name jaw crusher is derived from the crusher jaws necessary for crushing and the "chewing" []Coarse And Primary Crushing Machine Stone Crusher Rock Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crusher Premiertrak 330

Primary Jaw Crusher Home Facebook

Primary Jaw Crusher 643 likes 1JAW CRUSHER (Oil Type) Double Toggle, Double Wheel Double Toggle, Double Wheel, With Accessories Heavy duty type size : 48” x 36”Jaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge materialJaw Crushers McLanahanThe term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this service are much the same, regardless of how many Primary Crushing Mineral Processing MetallurgyLarge Capacity Reversible Primary Mobile Jaw Impact Hammer Stone Crusher by crushersplant posted in: News 0 Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but Large Capacity Reversible Primary Mobile Jaw Impact Hammer Primary jaw crushers typically operate in open circuit under dry conditions Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing The last crusher in the line of operation operates in closed circuit That is, the crushed product is screened and the oversize returned to the crusher Crusher an overview ScienceDirect Topics

Lokotrack® LT106™ mobile jaw crusher Outotec

Lokotrack® LT106™ mobile jaw crusher, or mobile jaw crushing plant as it is also called, is often used as a primary crusher in a multistage crushing process or as a standalone unit It is ideal for mediumsized aggregates production, as well as recycling demolition waste such as crus hing concrete , which can be reused as base material for Jaw crusher is the traditional crushing equipment with many models and large output PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushing There are many models of PE jaw crushers, among which the most popular models are PE750×1060, PE600×900, PE150×250, etcPE Series Jaw Crusher For Primary Crushing Jaw crushers are primary crushers, rock crushing equipment and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial use The crushing device consists of a fixed plate and a swivel plate called a jaw The rock is trapped and crushed between the jaw teethJaw crushers for your primary crushing VoghelOur Jaw Crusher is ideal for stationary, skidmounted, or portable and mobile primary crushing applications Call 8006480486 to find out moreJaw Crushers Rock Crushers Aggregate Crusher LEADER IN PRIMARY JAW CRUSHERS The jaw crusher is one of the most indispensable and preferred machines because of its performance and durability Depending on plant layout, jaw Crusher can be produced on wheels, skidmounted or fixed to the concrete foundationsJaw Crushers MEKA Crushing Screening Plants

What is a Jaw Crusher? Telsmith

Jaw crushers are mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industriesAdvantages of a Jaw Crusher Many factors make laboratory jaw crushers the optimum selection for effective and efficient primary crushing of hard, brittle, rocklike materials Laboratory models are available with sample top sizes from 075in to 8in (20mm to 203mm)What is a Jaw Crusher and Selecting the Right One Gilson CoPRIMARY COMPRESSION CRUSHING OF ABRASIVE MATERIAL If you can explain how a nutcracker works you can essentially envision the operation of a Liberty Jaw Crusher Inside the chamber there are two jaws One is fixed while the other constantly moves back and forth This action compresses the rock causing it to breakLiberty Jaw Crusher Primary Compression Crusher Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of What Is Primary, Secondary, and Tertiary Crushing?The Jaw crusher is used as Primary and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa There are two types of Jaw crusher : Compare this product Remove from comparison toolPrimary crusher, Primary crushing plant All industrial

8 Top Rock Crusher Brands Mellott Company

As they put it on their website, ’s selection “covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers – optimized for any size reduction need” Whether you need a primary rock crusher or a mobile plant, a machine is a solid option to considerHi everyone,I need to find the throughput (in tph) of a primary jaw crusher that is fed by a Grizzly screen O/S There is a throughput recorded for the grizzly screen feeding belt but how can I find the cutpoint of the grizzly screen? Would it be best to model it? Or could I use the sample data of tPrimary Jaw Crusher Throughput Crushing, Screening Specification of Primary Crusher Jaw Crusher DAIHO Primary Crusher Machine Stone crusher or stone crusher is a machine that is often used for mining or building construction purposes The stone breaking process itself has 3 stages, namely the primary, secondary and tertiary stages The stone crusher used at each stage is differentSell Primary Crusher Jaw Crusher DAIHORocksizer Jaw Crushers RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on Jaw Crushers Parker PlantBig Frontline Performance Mega Aggregate Plants Primary Jaw Crushers, Secondary Jaw Crushers, Horizontal Shaft Impactors, Vertical Shaft Impactors, Bucket Classifiers, Vibratory Screens, Nandhi Hydro Cyclone, Conveyers, and Storage HoppersJaw crushers Jaw Crushers Manufacturers Nandhi Crushers

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw