Case

cement mill specification in india

2023-07-02T05:07:28+00:00

cement ball mill in india

Cement Mill Specification In India Mining machine Cement grinding mill manufacturer in indiacement ball mill the current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1 per annum the electrical energy consumed in cement Cement Mill Specification In IndiaHistory of the origin of cement The British standard specification was first drawn up in 1904 The first ASTM specification was issued in 1904 In India, Portland cement was first manufactured in 1904 near Madras, by the South India Industrial Ltd But this venture failed Between 1912 and 1913, the Indian Cement Co Ltd, wasCement : Manufacture, Chemical Composition, Heat of Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD productioncement plant equipments manufacturer and suppliers of About Dalmia Cement Founded by Jaidayal Dalmia in 1939, Dalmia Cement is one of India’s pioneering cement companies Headquartered in New Delhi, the company operates as Dalmia Cement (Bharat) Ltd, which is in turn is a 100% subsidiary of Dalmia Bharat Ltd, listed on the National Stock Exchange and Bombay Stock Exchange (NSE: DALBHARAT; BOM: )Cement Manufacturing/Manufacturer Plants Cement Plants 4 PORTLAND CEMENT The cement procured by the Contractor or the clients shall be stored in a watertight room at the site The cement in this room shall be stored at least 600 mm away from the walls, 300mm clear from the floor, in rows, and 10 bags in height Cement shall confirm to IS: 269 The Contractor shall get the cement tested as per 1STA) GENERAL SPECIFICATIONS

Energy Source for Cement Kilns: KIS Knowledge is Power

Jan 10, 2008 KISPL meets coal quality specification for Cement Production JANUARY 10, 2008, NEW DELHI The two basic processes in cement production are the wet and dry processes which are named after the manner in which the raw mix is introduced into the kiln In the wet process the mix is introduced into the kiln as a slurry with 2040% moistureA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaDalmia Cement is one of the best cement brands in India Dalmia Cement is available in PPC, PSC, PCC, OPC 43 and OPC 53 variants It is the best cement for house construction, and considered the best cement for Oilwell, Airstrip, dams and all other infrastructure projectsDalmia Cement One of the Best Cement Companies in IndiaCement Mill Specification In India Mining machine Cement grinding mill manufacturer in indiacement ball mill the current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1 per annum the electrical energy consumed in cement Cement Mill Specification In Indiacement ball mill in indiaJan 10, 2008 Energy Source for Cement Kilns: KIS: KISPL meets coal quality specification for Cement Production: JANUARY 10, 2008, NEW DELHI The two basic processes in cement production are the wet and dry processes which are named after the manner in which the raw mix is introduced into the kiln In the wet process the mix is introduced into the kiln as a slurry with 2040% moistureEnergy Source for Cement Kilns: KIS Knowledge is Power

Cement Industry Reitz India

India ranks as the second largest producer of the Cement in the world Reitz India Limited is a major supplier of fans to the Indian cement industry with a substantial market share Modern cement making processes require wide range of demands on process fans including resistance to high abrasion, no excessive dust buildup and operation at high About Dalmia Cement Founded by Jaidayal Dalmia in 1939, Dalmia Cement is one of India’s pioneering cement companies Headquartered in New Delhi, the company operates as Dalmia Cement (Bharat) Ltd, which is in turn is a 100% subsidiary of Dalmia Bharat Ltd, listed on the National Stock Exchange and Bombay Stock Exchange (NSE: DALBHARAT; BOM: )Cement Manufacturing/Manufacturer Plants Cement Plants Cement complying with European and Sri Lankan standard specifications UltraTech's bulk cement terminal is located at Colombo in Sri Lanka Cement is received by speciallyengineered, selfdischarging bulk cement carriers It is then discharged at the port in road bowsers which transport cement 10 km from the port to the terminalTypes of Cement Best Cement Supplier in India UltraTechThe grinding media is manufactured by us in various specifications The exact specification is suggested by us to the customer depending on various factors such as: Material to be ground; Granulometry of the material; Grinding process (Wet/Dry) Importance of wear mechanisms involved (abrasion, corrosion, impact) Factors influencing the mill Grinding Media Shri BalajiDalmia Cement is one of the best cement brands in India Dalmia Cement is available in PPC, PSC, PCC, OPC 43 and OPC 53 variants It is the best cement for house construction, and considered the best cement for Oilwell, Airstrip, dams and all other infrastructure projectsDalmia Cement One of the Best Cement Companies in India

Birla Shakti

Installed Flender Combiflex Gearbox supplied by Krupp Polysius for cement mill 3 and 4 (India’s first) Gearboxes failures are commonly related to the misalignment of girth gear and uneven settlement of foundations The Combiflex drive system combines the advantages of the ring motor drive for low maintenance requirementJan 17, 2013 About the Industry Our country is the second major cement producing country following the China we have 140 large and 365 mini cement plants Leading players in the Industry are Ultratech,Gujarat Ambuja,JK Cement,ACC, Madras cement etc Southern region in the country is the biggest contributor in cement production India has total capacity Cement Industry and Audit PresentationOne of India's Top 3 Cement Producers Among one of India's fastest growing, with an installed cement production capacity of 404 Million Tonnes Per Annum in India and 444 including overseas This is supplemented by an installed Power Generation Capacity of 742 Mega Watts read moreHome Shree CementCoal ball mill is the equipment used for grinding and drying coal with different hardness It is also widely used to grind various hardness of coal in cement industry, metallurgy industry and Coal Mill Cement Mining Equipment SupplierBall Mill : Ball Mill for gold is a type of grinder It is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used asBall Mills at Best Price in India

Cement Mill Girth Gear at Rs /piece गर्थ गियर

Stotz Gears Pvt Ltd Offering Cement Mill Girth Gear, गर्थ गियर at Rs /piece in Ghaziabad, Uttar Pradesh Read about company Get contact details and address ID: India ranks as the second largest producer of the Cement in the world Reitz India Limited is a major supplier of fans to the Indian cement industry with a substantial market share Modern cement making processes require wide range of demands on process fans including resistance to high abrasion, no excessive dust buildup and operation at high Cement Industry Reitz IndiaAbout Dalmia Cement Founded by Jaidayal Dalmia in 1939, Dalmia Cement is one of India’s pioneering cement companies Headquartered in New Delhi, the company operates as Dalmia Cement (Bharat) Ltd, which is in turn is a 100% subsidiary of Dalmia Bharat Ltd, listed on the National Stock Exchange and Bombay Stock Exchange (NSE: DALBHARAT; BOM: )Cement Manufacturing/Manufacturer Plants Cement Plants ORDINARY PORTLAND CEMENT, 53 GRADE — SPECIFICATION (First Revision) ICS 9110010 Cement and Concrete Sectional Committee, CED 2 FOREWORD This Indian Standard (First Revision) was adopted by the Bureau of Indian Standards, after the draft finalized byIndian Standard ORDINARY PORTLAND CEMENT, 53 GRADE Jan 10, 2008 Energy Source for Cement Kilns: KIS: KISPL meets coal quality specification for Cement Production: JANUARY 10, 2008, NEW DELHI The two basic processes in cement production are the wet and dry processes which are named after the manner in which the raw mix is introduced into the kiln In the wet process the mix is introduced into the kiln as a slurry with 2040% moistureEnergy Source for Cement Kilns: KIS Knowledge is Power

A) GENERAL SPECIFICATIONS

4 PORTLAND CEMENT The cement procured by the Contractor or the clients shall be stored in a watertight room at the site The cement in this room shall be stored at least 600 mm away from the walls, 300mm clear from the floor, in rows, and 10 bags in height Cement shall confirm to IS: 269 The Contractor shall get the cement tested as per 1STCement complying with European and Sri Lankan standard specifications UltraTech's bulk cement terminal is located at Colombo in Sri Lanka Cement is received by speciallyengineered, selfdischarging bulk cement carriers It is then discharged at the port in road bowsers which transport cement 10 km from the port to the terminalTypes of Cement Best Cement Supplier in India UltraTechOne of India's Top 3 Cement Producers Among one of India's fastest growing, with an installed cement production capacity of 404 Million Tonnes Per Annum in India and 444 including overseas This is supplemented by an installed Power Generation Capacity of 742 Mega Watts read moreHome Shree CementJan 17, 2013 About the Industry Our country is the second major cement producing country following the China we have 140 large and 365 mini cement plants Leading players in the Industry are Ultratech,Gujarat Ambuja,JK Cement,ACC, Madras cement etc Southern region in the country is the biggest contributor in cement production India has total capacity Cement Industry and Audit PresentationCement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln Wikipedia

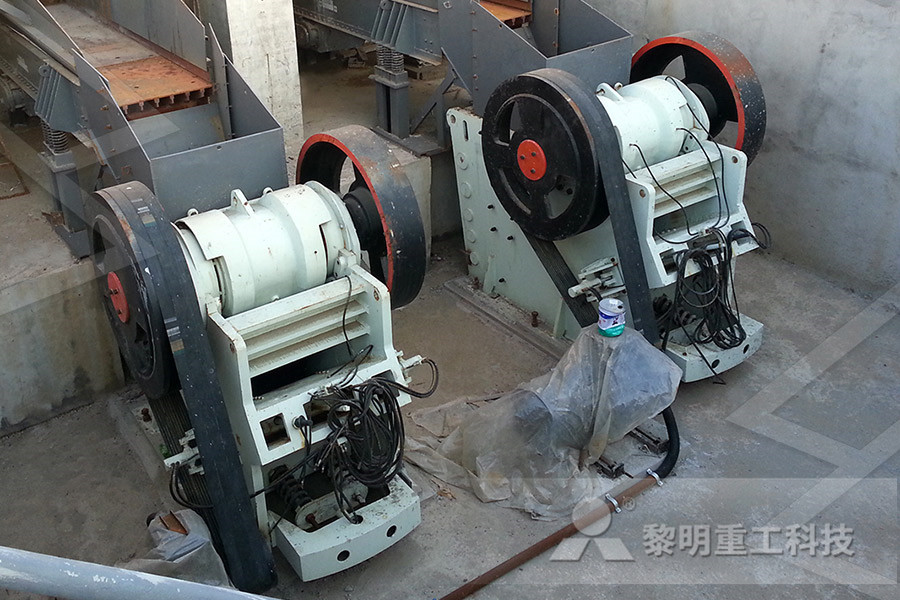

Second pilot production of limestone calcined clay cement

cement in India: The experience Arun C Emmanuel, Palas Haldar, Soumen Maity and Shashank Bishnoi Specification of ball mill Specifications Value Length of the ball mill 7725m Diameter of ICL is one of the leading cement producers in southern India with a total capacity of 155Mta The implementation of the OK™ vertical mill will enable ICL to reduce its energy costs, as the new mill will replace the existing ball mills at the plant estimates India Cements Ltd orders an OK™ millGet cement mill at best price with product specifications Listed cement mill manufacturers, suppliers, dealers exporters are offering best deals for cement mill at your nearby locationCement Mill, Cement Mill Manufacturers Suppliers, DealersRaw materials used in cement manufacturing If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the makingRaw materials Understanding Cement