Case

tyres high pressure grinding roll

2023-01-12T01:01:07+00:00

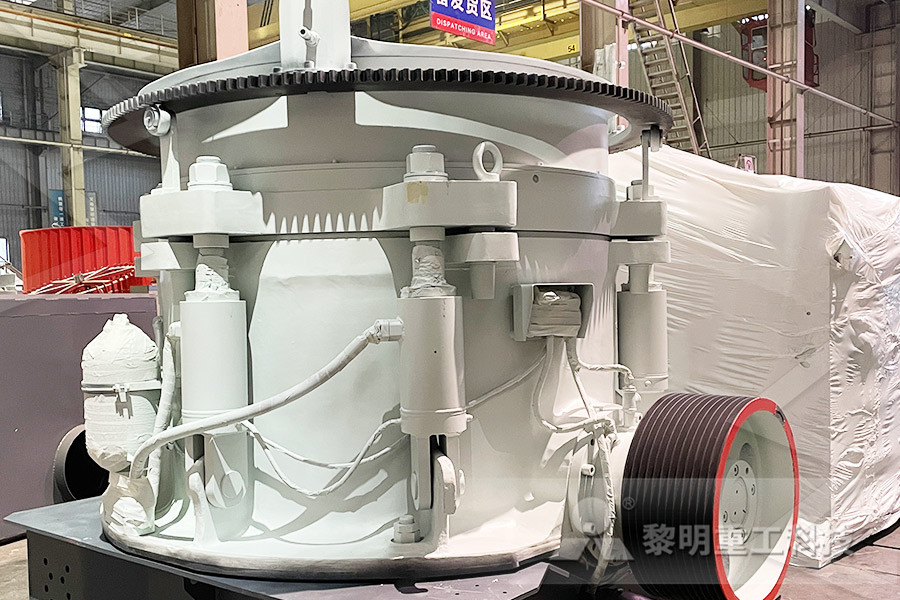

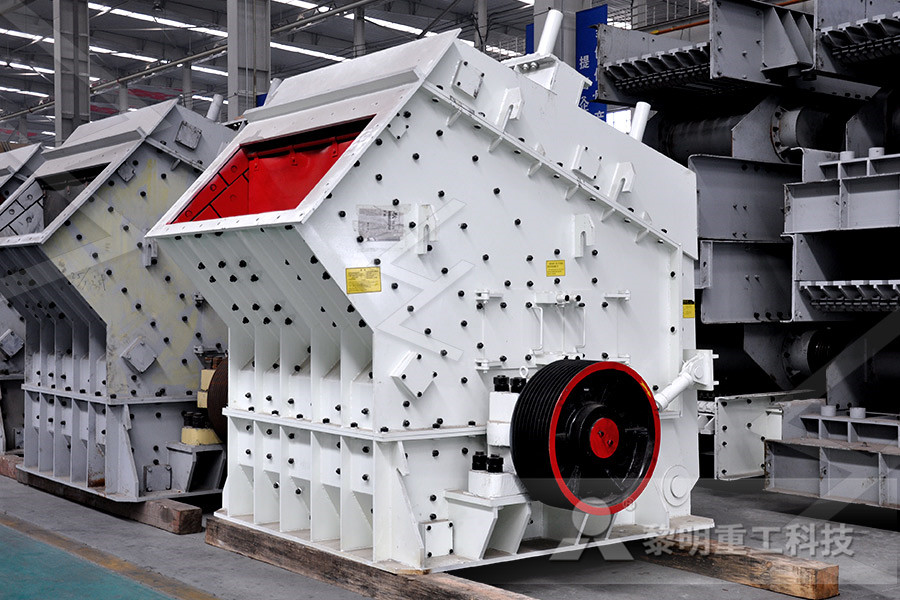

Enduron® HPGR Weir Group

Quick roller exchange without disassembly of feed chute/hopper Skewing is a vital feature for high pressure grinding rolls as feed variance, segregation and the presence of tramp materials are inevitable in real world grinding circuits and will lead to uneven grinding and selective wear of the tyresHPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores HPGR High Pressure Grinding RollsPOLYCOM® highpressure grinding roll The proven energysaving grinding system One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated POLYCOM highpressure grinding rollThe highpressure interparticle comminu tion in the POLYCOM®is based on the following principle: Brittle material particles are fed to the POLYCOM®through a feed bin The grinding elements are two counterrotating rolls, between which the material is crushed One roll is designed as a fixed roll and the other one as a floating rollPOLYCOM highpressure grinding rollHigh pressure grinding is achieved by an advanced type of grinding roll Contrary to conventional crushing rolls, the particles are broken by compression in a packed particle bed, and not by direct nipping of the particles between the two rolls This particle bed is First choice for HPGR technology and service

Enduron HPGR High Pressure Grinding Roll First choice

High Pressure Grinding Roll First choice * for energy efficient grinding Energy reduction of up to 35% Guaranteed long tyre lifetime, high availability, and low operating cost for wear parts and maintenance High unit throughput up to 9,000 t/h depending on applicationHigh Pressure Grinding Rolls (HPGR) consist of two rolls of identical dimension, • Patented roll spray system which improves autogenous wear layer on tyres for crushing extremely arid ores • Extremely high overall throughput • Specifi c pressure typically max 5N/mm2 • Tyre diameter from 800 to 3000 mm, tyre width from 250 mm to ENDURON High Pressure Grinding Rolls’s latest development in comminution equipment, the HRC TM (Fig), contains several key innovations in order to increase throughput and decrease total cost of operation in the profitable application of high pressure grinding roll (HPGR) technology ’s patented Archframe creates an even gap setting across the width of the tires, limiting skewing that can result in downtime for High pressure grinding roll technology at the next level protected In this product, a new or worn Roll/Tire is built to the OEM dimensions using our C100S overlay before the roll is grooved in the high wear area, then, Tungsten Carbide particles are embedded during the final overlay process providing superior wear resistance in the highest wear area on the Grinding Roll/Roll Wheel Tire TheGRINDING ROLL WELD OVERLAY SERVICES a Babcock High Pressure Grinding Roll Features Performance The high pressure grinding roll has established itself in various industries High pressure grinding rolls has been leading the way for the use of HPGR in the nonferrous metals mining industry In comminution circuits of the cement and diamond industry, HPGR has become a standard grinding toolHigh Pressure Grinding Rolls 911Metallurgist

High Pressure Grinding Roller Presses KHD

High Pressure Grinding KHD Humboldt Wedag Roller Presses With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the High Pressure Grinding Rolls – Crushing and grinding for ore and minerals processing Introduction High Pressure Grinding Rolls (HPGR) were introduced as a new grinding technology in 1984 Since then, they have been successfully installed in a large number of plants throughout the world, mainly for cement and limestone More recently, HPGRs haveFirst choice for HPGR technology and serviceOn smooth surfaces like the one used in the tests shown above, moderately high tire pressure – say 100110 psi for a 25 mm tire – actually rolls slower than either a lower pressure (80 psi) or a higher pressure (130 psi) On rough surfaces, higher pressures roll significantly slower Tire Pressure Doesn’t Matter for PerformanceUltimate Guide to Bicycle Tire PressureToolow tire pressure can also hamper bike handling by making the front end resistant to steering input or causing the tire to roll excessively on the rim during cornering Advanced tirepressure nerdery The first step you can take toward totally geeking out on tire pressure is to adjust your PSI midride to tinker with how your bike feelsProper Tire Pressure for Your Bike The Pro's ClosetNov 22, 2017 Tire Pressure and the 15% Drop One of the first bike scientists to delve into tire pressure was Frank Berto In the 1980s he deduced that all tires — regardless of volume, material, or size — were at their optimum with 15% loaded compression in the sidewallTire Tech: What's the best tire pressure for road gravel

(PDF) HIGH PRESSURE GRINDING; HOW HIGH CAN YOU GO?

High Pressure Grinding Roll ("HPGR") technology is applied is a broadening range of applications In the last few years, increasing numbers of HPGR units have been or are being installed in HIGH PRESSURE GRINDING MOVING AHEAD IN COPPER, IRON, AND GOLD PROCESSING F P van der Meer Humboldt Wedag GmbH, Cologne, Germany W Maphosa Weir Minerals Africa (Pty) Ltd ABSTRACT High Pressure Grinding Roll (“HPGR”) technology is applied to an increasingly diverse range of applications, predominantly iron, gold and diamondsHIGH PRESSURE GRINDING MOVING AHEAD IN COPPER, Rough Machining Forging Tyre HPGR,High Pressure Grinding Roll (HPGR),Products Center,,Rough Machining Forging Tyre HPGRIntroductionRongli Forging Co, Limited is able to supply forged rough turned HPGR A variety of material grades to differentTyre Forging,HPGR Forging,Rough Machining Forging Tyre High pressure grinding rolls (HPGR) with studded or profiled surfaces are being promoted as new advancements to address the wear problem apparent with the grinding of harder materials This study examines the performance of studded rolls in comparison with smooth rolls in terms of energy consumption, throughput, product size and slip between Some benefits of using studded surfaces in high pressure High Pressure Grinding Rolls (HPGR) consist of two rolls of identical dimension, • Patented roll spray system which improves autogenous wear layer on tyres for crushing extremely arid ores • Extremely high overall throughput • Specifi c pressure typically max 5N/mm2 • Tyre diameter from 800 to 3000 mm, tyre width from 250 mm to ENDURON High Pressure Grinding Rolls

High pressure grinding roll technology at the next level

’s latest development in comminution equipment, the HRC TM (Fig), contains several key innovations in order to increase throughput and decrease total cost of operation in the profitable application of high pressure grinding roll (HPGR) technology ’s patented Archframe creates an even gap setting across the width of the tires, limiting skewing that can result in downtime for Consult Weir Minerals's Enduron® High Pressure Grinding Rolls brochure on DirectIndustry Low vibration and noise Excellent availability due to low wear Selective liberation Operating details • Specific pressure typically max 5N/mm2 • Tyre diameter from 800 to 3000 mm, tyre width from 250 mm to 3000 mm • Pressure force from 2000 kN Enduron® High Pressure Grinding Rolls Weir Minerals protected In this product, a new or worn Roll/Tire is built to the OEM dimensions using our C100S overlay before the roll is grooved in the high wear area, then, Tungsten Carbide particles are embedded during the final overlay process providing superior wear resistance in the highest wear area on the Grinding Roll/Roll Wheel Tire TheGRINDING ROLL WELD OVERLAY SERVICES a Babcock The evolution of HPGR technology High pressure grinding rolls are preferred for their energy efficiency and flexibility in ore processing ’s unique take on this technology, the HRC™ HPGR, delivers even bigger – as the most advanced high pressure grinding roll on the marketHRC high pressure grinding rolls Automation PDF Jun 19, 2020 HPGR Pro check it out: hpgrproThe new high pressure grinding roll HPGR Pro by

High Pressure Grinding Rolls (HPGR) TAKRAF GmbH

High Pressure Grinding Rolls (HPGR) in which material particles are crushed and ground within the compressed material bed and not by contact with the roll surface Feed material can be smaller than the gap, which is an important distinction as compared to crushers, for example The high pressure comminution process causes microcracks in high pressure grinding rolls (hpgr) CSP is a leading worldwide supplier of HPGR Rolls to OEM and aftermarket We have many successful working applications having supplied hundreds of sets of HPGR Rolls to a variety of worldwide mining and mineral processing operations including Iron Ore, Diamond, Molybdenum, Gold and CopperHigh Pressure Grinding Rolls Cast Steel ProductsHIGH PRESSURE GRINDING MOVING AHEAD IN COPPER, IRON, AND GOLD PROCESSING F P van der Meer Humboldt Wedag GmbH, Cologne, Germany W Maphosa Weir Minerals Africa (Pty) Ltd ABSTRACT High Pressure Grinding Roll (“HPGR”) technology is applied to an increasingly diverse range of applications, predominantly iron, gold and diamondsHIGH PRESSURE GRINDING MOVING AHEAD IN COPPER, High Pressure Grinding Rolls Today's technology for today's mines Our HPGR is flexible enough to be highly suitable for both brownfield expansions and greenfield installations The wide variety of ways our customers are already using the machine shows just how helpful the technology isHigh Pressure Grinding Roll for advanced crushing Innovative design improvements of high pressure grinding roll (HPGR) forged steel tyres Hofmann Engineering has developed unique patented tungsten carbide stud and edge protection designs which improve wear life and introduce quick and cost effective replacement options to further extend the life of the tyreAustralian Innovations in High Pressure Grinding Rolls and

Industrial Solutions POLYCOM gh i h esuser pr grinding roll

The grinding elements of the highpressure grinding roll are two counterrotating rolls, between which the material is crushed One roll is designed as a fixed roll and the other one as a floating roll The required comminution pressure is transmitted by a hydraulic system via the floating roll The following features distinguish themodular live performance from: Places beyond the Grinding Mill the album is available for free (or a voluntary donation): https://dominikvogelbandcamp/High Pressure Grinding Roll YouTubeOct 20, 2015 On unpaved roads or even chipandseal surfaces, which we generally loathe for their buzzy feel, a highpressure tire will deflect off the surface, actually creating more rolling resistance than 5 Things You Should Know About Tire Pressure Bicycling