Case

milling and flotation of slow oled pper slag.html

2020-02-24T06:02:02+00:00

Optimization of the flotation of copper smelter slags from

The slags cannot be discarded due to the high content of copper and hence they are sent to a milling and flotation plant (Slag Mill Plant) for liberation and recovery of copper This work focuses on optimizing the recovery of copper minerals in copper smelter slags by means of froth flotationApr 05, 2015 Technological procedure of slow cooling slag from primary copper production is applied in the purpose of copper recovery in the level of 985% to blister This technological procedure is divided into two phases, first slow cooling of slag on the air for 24 hours, and then accelerated cooling with water for 48 hoursTHE EFFECT OF COOLING RATE OF SLAG FROM PRIMARY A process for controlled slow cooling of nonferrous smelting slags, such as copper slags, for the recovery of the nonferrous metals contained therein by subsequent crushing, milling and flotationUSA Process for controlled slow cooling of non Jul 31, 2020 Milling and froth flotation methods are quite common when dealing with slowcooled slags Before flotation, the slag needs to be cooled in a controlled manner There are multiple options for this, such as natural cooling, casting mill cooling, water quenching, and slow cooling in a Effect of Cooling Rate and Slag Modification on the Copper The recovery of copper by floatation from slow cooled Ausmelt furnace slag was studied in this paper The phases and composition of the slow cooled slag were analyzed The factors which affected the copper recovery efficiency such as grinding fineness, pH value of flotation medium, different collectors and floating process were investigatedRecovery of Copper from Slow Cooled Ausmelt Furnace Slag

Recovery of copper from copper slag and copper slag

When the slag were ground below 74?mby ball milling, the recovery of copper by floation in slag improved to 78 83% because of copper liberation effect View Show abstractmilling and flotation of slow cooled copper slag Slag milling copper copper slag milling and flotation process It is here that S slag from the cooled Kress pots is ground and prepped for use as a furnace coolant and to recover the small amount of copper still contained in the slag Kress pots are cooled by the application of water introduced into the pot over the hot slagget pricemilling and flotation of slow cooled copper slagMetallurgical ContentA Copper Flotation FlowsheetCOPPER MININGCRUSHING COPPER ORECOPPER ORE STORAGEGRINDING COPPER ORECOPPER FLOTATION CIRCUITCOPPER THICKENING AND FILTERINGPROCESS CONTROLSCopper Flotation Process SummaryFlotation of Copper Ores Although basic porphyry copper flotation and metallurgy has remained virtually the Copper Flotation Mineral Processing MetallurgyThe copper slag used in the experiments is a byproduct generated during the cleaning of electric furnace slag and refining of copper in Tongling Nonferrous Metals Group Holding Co, Ltd (Tongling, China) As shown in Table1, the main chemical compositions contained in the waste slag are 4285 wt %Improving Beneficiation of Copper and Iron from Copper flotation process began in the nineteenth century, but flotation is considered the most important devel opment of the twentiethcentury mining and milling industry Flotation Flotation is an innovative processing method for separating valuable minerals locked in waste rock It abandons basic principles of ore treatment by gravityTo Float or Sink: A Brief History of Flotation Milling

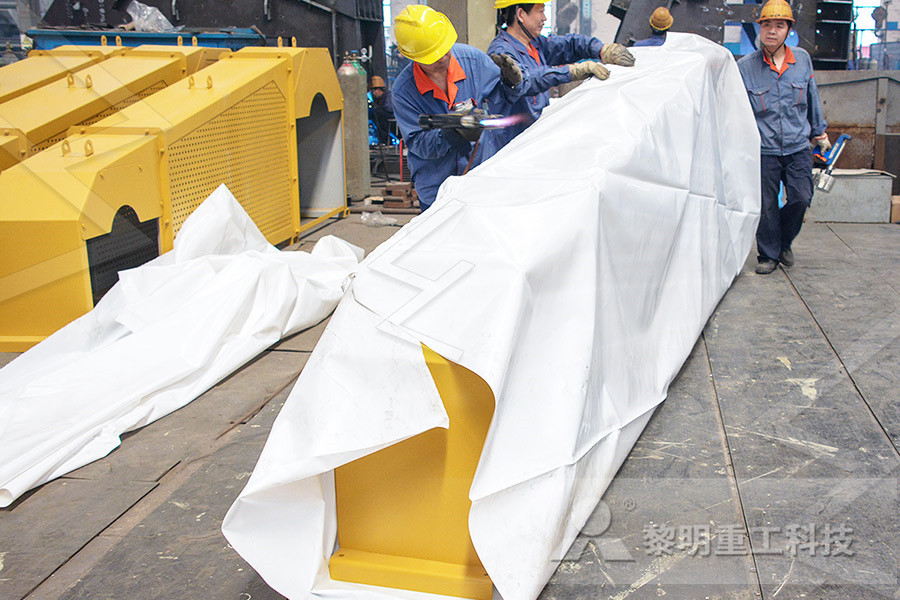

Laboratory Test Works and Plant Trials for Milling and

Mar 17, 2012 Laboratory Test Works and Plant Trials for Milling and Flotation of Slow Cooled Copper Slag Pengfii Tan for more papers by this author Alberto Oalvez for more papers by this author Lucya Yunus for more papers by this author Xstrata CopperJul 31, 2020 Milling and froth flotation methods are quite common when dealing with slowcooled slags Before flotation, the slag needs to be cooled in a controlled manner There are multiple options for this, such as natural cooling, casting mill cooling, water quenching, and slow cooling in a ladle Effect of Cooling Rate and Slag Modification on the Copper ABSTRACT OF THE DISCLOSURE: A process for controlled slow cooling of nonferrous smelting slags, such as copper slags, for the recovery of the nonferrous metals contained therein by subsequent crushing, milling and flotation operations is disclosed The process comprises the steps of pouring the molten slag into a ladle, allowing the slag to slowly cool and solidify in the ladle at least to CAA Process for controlled slow cooling of non Mar 01, 2004 Flotation experiments were then carried out on this slowcooled slag Table 3 compares the results of the flotation experiments of the slags with different cooling rates, while the particle size of the copper minerals in the slag can be seen in the microscopic photographs of Fig 1, Fig 2Recovery of copper from reverberatory furnace slag by Milling And Flotation Of Slow Cooled Copper Slag After the slag is cooled and crushed, it is processed in a flotation column where the floating material is high in copper and is returned to the process copper columbia engineering jan 14, 1992 from primary copper processing, and slag tailings from primary copper processing, are subject to Copper Flotation Plant Process Description

copper slag milling and flotation process

milling and flotation of slow cooled copper slag techniques, such as slag cleaning, slow cooling of the slag followed by milling and flotation, are inappropriate for cobalt recovery from converter slag [7−8] Read More Minimization of Copper Losses in Copper Smelting Slag DuringMilling And Flotation Of Slow Cooled Copper Slag Techniques such as slag cleaning slow cooling of the slag followed by milling and flotation are inappropriate for cobalt recovery from converter slag 78 Minimization of Copper Losses in Copper Smelting Slag During READ MORECopper Slag Flotation Process Dustri MachinerySep 21, 2012 Smelters using slag milling and flotation for slag cleaning generally operate under conditions where most of the copper in slag would tend to form Cu 2 S upon cooling, although some metallic copper may still form via reaction 37 Ideally, the slag should be slow cooled to allow most of the copper to form larger matte prills (over 30 μm in size Minimization of Copper Losses in Copper Smelting Slag To reach high copper extraction indices, flotation requires preliminary slow cooling in order to form phases, which are broken down during fragmentation [10, 11] An increase in the cooling rate Recovery of copper from reverberatory furnace slag by Milling Milling And Flotation Of Slow Cooled Copper Slag impacts of slag mill and flotation autospeccoza milling and flotation of slow cooled copper slag impacts of slag mill and flotation sand washing machine copper slag milling and flotation process imsrcoin froth flotation slow cooled copper slag sayorain impacts Get DetailImpacts Of Slag Mill And Flotation

Recovery of cobalt, nickel, and copper from slags, using

Slags are sometimes treated by slow cooling, milling, and flotation This approach is satisfactory when the metals in the slag are in either the sulphide or metallic form, Mar 15, 2019 Tailings from an industrial copper slag cleaning milling and flotation circuit have been prereduced at low temperatures, well below its melting point, using CH 4H 2Ar mixtures with the aim of metallizing its iron oxide component to metallic ironThe treatment carried out at 700–900 °C, with a duration of up to 90 min, indicated a complete transformation of magnetite within the first 30 Upgrading copper slag cleaning tailings for reuse Xstrata needed to improve copper recovery and called on Orica to identify and test collectors Orica formulated a collector that would enhance milling and flotation of slow cooled copper slag Ultimately, the process needed to achieve superior recovery of copper at a natural pH over a specific grind fineness Xstrata’s key requirements were to:Orica’s flotation reagents increase copper recovery rates froth flotation slow cooled copper slag « mill gold froth flotation slow cooled copper slag Description : part, la Bulgarie est un producteur important d'herbes Get Price Here! copper slag flotation plant copper slag concentrator copper slag flotation plantMilling And Flotation Of Slow Cooled Copper Slag After the slag is cooled and crushed, it is processed in a flotation column where the floating material is high in copper and is returned to the process copper columbia engineering jan 14, 1992 from primary copper processing, and slag tailings from primary copper processing, are subject to Copper Flotation Plant Process Description

Orica’s flotation reagents increase copper recovery rates

Xstrata needed to improve copper recovery and called on Orica to identify and test collectors Orica formulated a collector that would enhance milling and flotation of slow cooled copper slag Ultimately, the process needed to achieve superior recovery of copper at a natural pH over a specific grind fineness Xstrata’s key requirements were to:milling and flotation of slow cooled copper slag techniques, such as slag cleaning, slow cooling of the slag followed by milling and flotation, are inappropriate for cobalt recovery from converter slag [7−8] Read More Minimization of Copper Losses in Copper Smelting Slag Duringcopper slag milling and flotation processMar 15, 2019 Tailings from an industrial copper slag cleaning milling and flotation circuit have been prereduced at low temperatures, well below its melting point, using CH 4H 2Ar mixtures with the aim of metallizing its iron oxide component to metallic ironThe treatment carried out at 700–900 °C, with a duration of up to 90 min, indicated a complete transformation of magnetite within the first 30 Upgrading copper slag cleaning tailings for reuse Sep 21, 2012 Smelters using slag milling and flotation for slag cleaning generally operate under conditions where most of the copper in slag would tend to form Cu 2 S upon cooling, although some metallic copper may still form via reaction 37 Ideally, the slag should be slow cooled to allow most of the copper to form larger matte prills (over 30 μm in size Minimization of Copper Losses in Copper Smelting Slag Slag Cooling stpd 9% copper Copper 1526 180 275 396 700 277 Copper recovery from slag is dependent on the treatment of the material prior to beneficiation at the mill Slow cooling in the initial stages is imperative to allow copper particles to coalesce and crystallizeSlag reprocessing: Magma Copper Company's San Manuel

Recovery of cobalt, nickel, and copper from slags, using

Slags are sometimes treated by slow cooling, milling, and flotation This approach is satisfactory when the metals in the slag are in either the sulphide or metallic form, froth flotation slow cooled copper slag « mill gold froth flotation slow cooled copper slag Description : part, la Bulgarie est un producteur important d'herbes Get Price Here! copper slag flotation plant copper slag concentrator copper slag flotation plantslow cooled, crushed, and sent to the Magnetic Concentration Plant at the Rustenburg Base Metals Refinery (RBMR) Here, the magnetic PGMcontaining fraction is removed and sent to the PMR, while the remaining material is treated at the RBMR to recover nickel, copper, and cobalt At the PMR, the PGMs are separated and refined to produce pure metalsProcess Description and Abbreviated History of Anglo nickel ore flotation plant and machine froth from a poor processing ore antimony mining flotation tank for sale flotation machine price flotation machine kyf 16 aerator equipment used flotation of coal milling and flotation of slow cooled copper slag flotation mill process smaller froth flotation machine gold crusher and flotation Get Pricecopper slag concentrate process flotatoin machineFor example, they can be cooled in the air or slow cooled in induction furnaces or water quenched before they are milled and subjected to froth flotation The copper recovery from the converter slags will largely depend on this initial cooling treatmentDore slag treatment Noranda Mines Limited

copper flotation recovery rates southportline

Oct 01, 2019 flotation minerals engineeringfroth zone recoveries and the gangue entrainment into the concentrate was also evaluated the mineral in the flotation feed was characterized by particle sizeorica's flotation reagents increase copper recovery rates, resulting in orica formulated a collector that would enhance milling and flotation of slow cooled copper slag ultimately, the process Ball Mill Economic New Cement Clinker Milling Production Cement grinding mill from china bridgingbordersch china ball millscement ball millsball grinding mill china ball mills cement ball mills ball grinding mill a pplication ball mill is widely used in powdermaking production line which include silicate newtype building material cement refractory material fertilizer glass ceramics and so onNews On Sand Making Production Process Slag Ball MillingThe bearing lining is provided with a snakeshaped cooling water pipe, which can supply cooling water when necessary to reduce the temperature of the bearing bush The cooling water pipe is made of red copper which has certain corrosion resistance Ball mill power is relatively large, the appropriate choice of hydrostatic sliding bearing The What's the Difference Between SAG Mill and Ball Mill