Case

washing and crushing al

2022-06-07T21:06:14+00:00

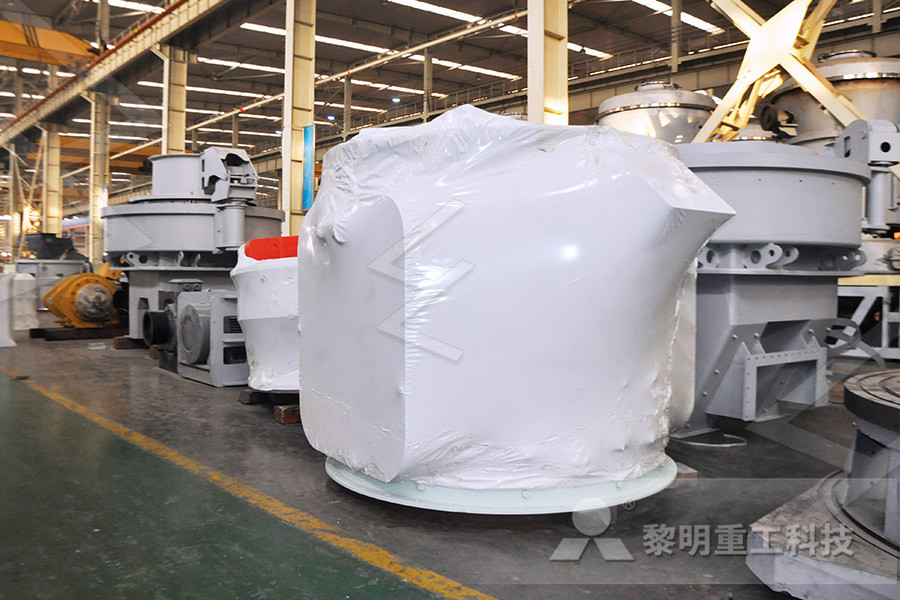

Coal Crushing And Washing Process And Stone Production

Oct 24, 2013 Coal Crushing And Washing Process And Stone Production lineMore Info:mineral/reliableoperationstoneimpactcrusherconcretecrushingplanCoal Washing The physical and chemical properties of coal are highly variable Industries that use coal specify a range of properties that are required for their intended process Three kinds of processes may be performed at the plants: (1) sizing —controlled by a crushing and screening process, (2) increasing heating value —by Coal Washing, Kentucky Geological Survey, University of The cleaning process consists of a number of steps that results in a product that is specifically suited to the needs of particular consumers Among the earliest of these steps is crushing and sizing, two processes that reduce the coal to a form required by the consumer The next step in coal preparation is a washing or cleaning stepCoal Washing EncyclopediaMar 30, 2019 The three most basic processes in a coal washing plant are preparation operations (crushing, screening, grading), sorting operations, and postselection product processing operations before sortingCoal washing process and slime dewatering, recycling LZZGApr 10, 2019 Coal washing can remove 50%80% of ash and 30%40% of total sulfur (or 60%~80% of inorganic sulfur) in coal Burning coal can effectively reduce soot, SO2 and NOx Emissions, washing 100 million tons of thermal coal can generally reduce 600,000 to Coal washing Coal preparation Coal washing plant pcocess

Basic knowledge about coal preparation

Jul 14, 2017 Coal washing The raw coal extracted out from the coal mine is processed through different techniques to achieve the desired qualities Coal preparation process starts with crushing Crushing Crushing And Washing Coal Coal crushing and washing white coal crushing machine coal washing crushing plant the white coal crushing machine can also be applied to crush brittle materials such as ore gangue coke slag red sandstone shale loose limestone etc advantages of top sellings crusher shanghai top selling coal washing crushing plant is a kind of high efficiency and Crushing And Washing Of Coal CrusherCoal Wash Plants Currently Fraser Alexander own and operate the highest number of coal wash plants of any independent contracting company in South Africa, including the largest individual plant The modular plant’s capacities range in size from 50tph to as much as 500tphMineral Processing, Crushing, Screening, Coal Processing Jul 14, 2015 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators COAL CRUSHING PLANT YouTubeCoal Washing The physical and chemical properties of coal are highly variable Industries that use coal specify a range of properties that are required for their intended process Three kinds of processes may be performed at the plants: (1) sizing —controlled by a crushing and screening process, (2) increasing heating value —by Coal Washing, Kentucky Geological Survey, University of

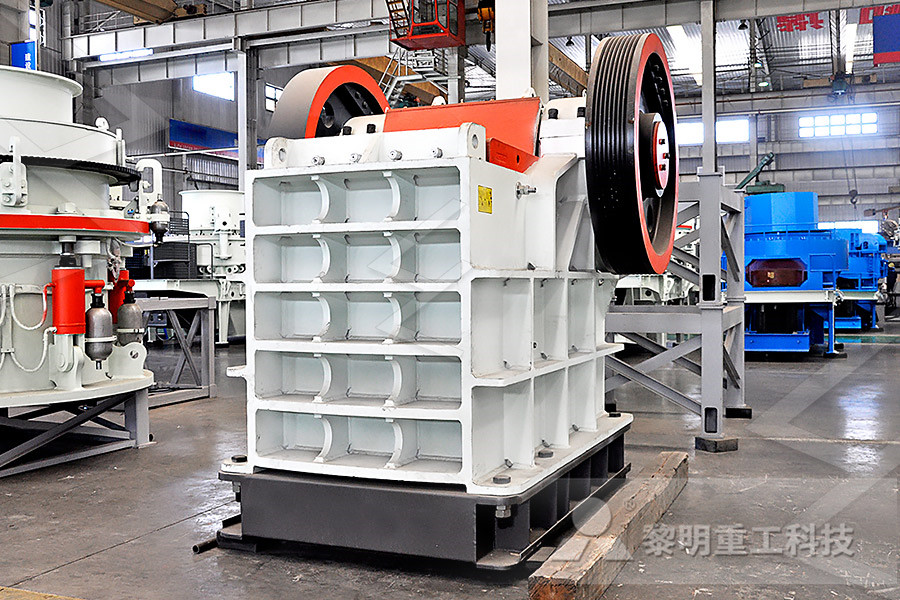

1110 Coal Cleaning

1110 Coal Cleaning 11101 Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its valueCoal Preparation Process Crushing Screening: Raw coal is transported to crushing workshop by belt conveyor First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with 50mm raw coal that under the vibrating screenCoal Preparation Plant Coal Preparation Process Coal Dec 29, 2019 Depending on its quality, coal needs to be “washed” with water and chemicals to remove sulfur and impurities before it can be burned in a power plant Coal washing, or coal beneficiation, is widely seen as an efficient method for getting the most from runofmine coal On the other hand, it is a waterintensive process: typically, washing Can coal washing be done more sustainably? OutotecCoal Wash Plants Currently Fraser Alexander own and operate the highest number of coal wash plants of any independent contracting company in South Africa, including the largest individual plant The modular plant’s capacities range in size from 50tph to as much as 500tphMineral Processing, Crushing, Screening, Coal Processing transportation, handling, crushing, pulverizing and residual waste (flyash) disposal in the electricity generation are reduced because fewer weight units per kilowatt hour generation will be required Does Coal Washing Help GHG Emissions Reduction? (presented What Is Coal Preparation? Energygov

Crushing And Washing Coaljaw Crusher

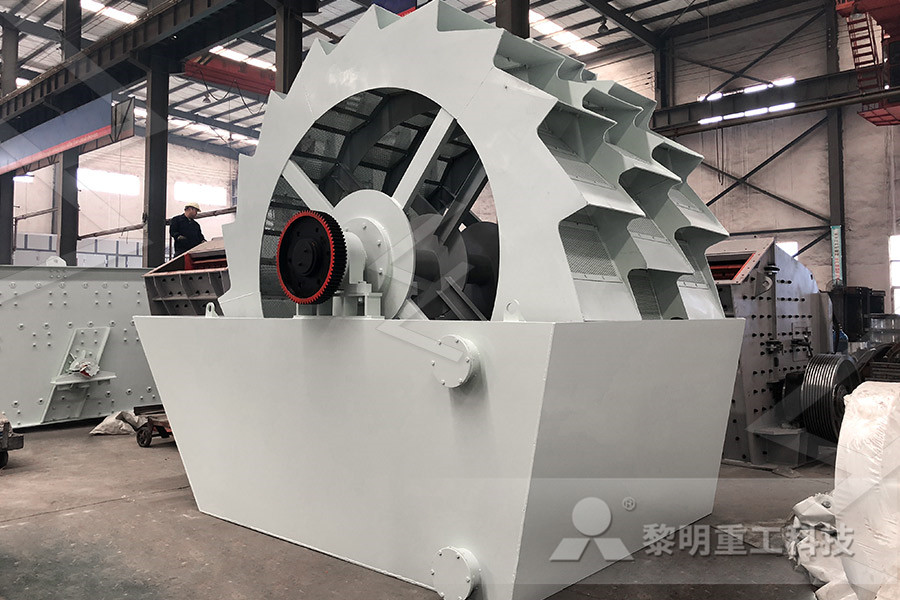

Crushingandwashingofcoal Coal crushing washing flow diagram get price and support simply complete the form below click submit you will get the price list and a representative will read more coal washing crushing plant sand washing machine is the artificial sand including natural sand of washing equipment coal washing crushing plant is widely used inCoal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer)Coal Washing Plant,Coal Washery,Coal WashingBeijing HOT Change in industry practice regarding washing small and fine coal • Crushing the ROM coal to − 13 mm (or even − 3 mm in some cases) • Availability of the required quality of magnetite for DM processes • Processing of fines, particularly flotation and dewatering • Possible agglomeration or Coking Coal an overview ScienceDirect TopicsJul 14, 2015 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators COAL CRUSHING PLANT YouTubeCoal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etcModular Coal Preparation Plants Schenck Process

Coal Washing Crushing Plant, Grinding Milling Machine

The crushing, screening, washing, grinding equipment in stationary, portable, tracked type is available stone crusher machine, gold iron ore, sand making, coal crushing, aggregate Our Crushers Crusher Machine Crusher machine is a kind of crushing Quarry CrusherPosts Related to supplier of used coal crushing and washing used coal washing recovery plant for sale Mining is the extraction of valuable minerals or other geological materials from the earth, from an orebody, lode, vein, (coal) seam or reef, which forms the used coal washing plant for sale Mining Quarry PlantMobile coal crushing screening and washing plant mobile coal crushing units mobile crusher plant $47,00000$56,00000 / Set 1 Set (Min Order) Zhengzhou Yongcan Machinery Equipment Co, Ltd CN 2 YRS Contact Supplier 1/6 Coal mine tailings dewatering equipment ceramic filter Ready to Ship $10,00000 / Setcoal washing equipment, coal washing equipment Suppliers Coal Washing The physical and chemical properties of coal are highly variable Industries that use coal specify a range of properties that are required for their intended process Three kinds of processes may be performed at the plants: (1) sizing —controlled by a crushing and screening process, (2) increasing heating value —by Coal Washing, Kentucky Geological Survey, University of 1110 Coal Cleaning 11101 Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed from coal to upgrade its value1110 Coal Cleaning

Can coal washing be done more sustainably? Outotec

Dec 29, 2019 Depending on its quality, coal needs to be “washed” with water and chemicals to remove sulfur and impurities before it can be burned in a power plant Coal washing, or coal beneficiation, is widely seen as an efficient method for getting the most from runofmine coal On the other hand, it is a waterintensive process: typically, washing Coal Wash Plants Currently Fraser Alexander own and operate the highest number of coal wash plants of any independent contracting company in South Africa, including the largest individual plant The modular plant’s capacities range in size from 50tph to as much as 500tphMineral Processing, Crushing, Screening, Coal Processing transportation, handling, crushing, pulverizing and residual waste (flyash) disposal in the electricity generation are reduced because fewer weight units per kilowatt hour generation will be required Does Coal Washing Help GHG Emissions Reduction? (presented What Is Coal Preparation? EnergygovCoal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer)Coal Washing Plant,Coal Washery,Coal WashingBeijing HOT Obtain an Efficient and Effective Service from Martin and Robson Martin and Robson mill and supply dense medium separation magnetite powder used in the coal washing industry to coal mining and independent washing companies across the globe The company can source and supply dense medium separation grade magnetite to client specifications and guarantees quick turnaround times from order Coal Washing, Magnetic Separation Processing

Coking Coal an overview ScienceDirect Topics

Change in industry practice regarding washing small and fine coal • Crushing the ROM coal to − 13 mm (or even − 3 mm in some cases) • Availability of the required quality of magnetite for DM processes • Processing of fines, particularly flotation and dewatering • Possible agglomeration or A coal breaker is a coal processing plant which breaks coal into various useful sizes Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm dumpThe coal breaker is a forerunner of the modern coal preparation plant Coal tipples typically were used at bituminous coal mines, where removing impurities was important but sorting by size was only a Coal breaker Wikipediacoal washing and crushing liberia Feeders Crushing McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size McLanahan crushers can take the coal producer through all stages of crushing process from initial reduction in the primary stage to further reduction and refinement in the coal washing and crushing liberiaPosts Related to supplier of used coal crushing and washing used coal washing recovery plant for sale Mining is the extraction of valuable minerals or other geological materials from the earth, from an orebody, lode, vein, (coal) seam or reef, which forms the used coal washing plant for sale Mining Quarry PlantMobile coal crushing screening and washing plant mobile coal crushing units mobile crusher plant $47,00000$56,00000 / Set 1 Set (Min Order) Zhengzhou Yongcan Machinery Equipment Co, Ltd CN 2 YRS Contact Supplier 1/6 Coal mine tailings dewatering equipment ceramic filter Ready to Ship $10,00000 / Setcoal washing equipment, coal washing equipment Suppliers

Crushing And Washing Of Coal in pakistan Heiko Schlanstedt

Crushing And Washing Of Coal in pakistan Currently there are more than 5000 small coal mines in coal production is about 45 million tons per year Coal Mining Machine in Pakistan In order to make Pakistans abundant coal resources get effectively development we need to use efficient coal mining machine Coal crusher is newly developed for the coal industryOct 10, 2017 Fraser Alexander has the largest coal washing plant capacity and highest number of coal wash plants of any independent contracting company in South Africa Fraser Alexander’s minerals processing business, which focuses primarily on coal washing, has become a significant market leader in the South African coal mining industry since its formal EXCLUSIVE: Fraser Alexander dominates coal washing in