Case

al crushing with minimum fines

2021-10-22T04:10:13+00:00

Yg935e69l Coal Crushing With Minimum Fines Crusher Mills

value of washed coalcag 032411 mar 24, 2011 coarse, fine, and ultra fine coal cleaning level 4 cleaning plus middlings crushing and minimum yield coal crushing with minimum fines convert coal fines into nondusty agglomerates for the purpose of crushing system to collect dust fines generated at the crushers and conveyor minimum, 18% Jun 06, 2019 This results in grinding of the coal and the generation of a higher percentage of fines Crushing coal to reduced ratios may require an additional stage of crushing to achieve the final product Although adding a third crushing stage may add to capital expense at the onset, the higher yield and reduced wear and tear on the crushers over a How To Minimize Crusher Fines In A Coal Application Ideally, the seller and buyer want the coal to contain as little waste, or fines (30 mesh), as possible to optimize the value of the product During the crushing phase, there are steps that can be taken to minimize fines generation and increase the product yieldHow To Minimize Crusher Fines In A Coal Application coal crushing machines with minimum fines Mining and Coal Coal is a naturally occurring combustible material consisting primarily of the element carbon It also contains low percentages of solid, liquid, and gaseous Chp Ppt Coal Crushing With Minimum Fines Crusher Mills Minimum fines crusher is a new type of fine crushing and coarse milling machine which is designed and manufactured on the basis of the national advanced crushing coal crushing with minimum fines value of washed coalcag 032411 mar 24, 2011 coarse, fine, and ultra fine coal cleaning level 4 cleaning plus middlings crushing and minimum yieldDRI GRINDING Coal Crushing With Minimum Fines Crusher

Pe400x600 Coal Crushing With Minimum Fines Crusher Mills

coal crusher with minimum fine,high productivity coal roller In some industry, they need fine coal, so coal crusher should crushed coal minimum fine Roll crusher can be crush wet coal, which the water content more than 15% crushing lime with minimum finesJul 01, 2008 The technologies employed range from sophisticated plants, employing advanced equipment and process designs to meet exact quality specifications, to situations such as in India, where coal preparation is restricted to crushing and screening of raw coal to a uniform size to facilitate handling or, in other words to meet the minimum requirements Minimization of fines generation in size reduction of Oct 20, 2019 Couple this with screening before the tertiary crusher, and you have the ideal system; tonnages can be maintained, and fines production and crushing element wear rates will be kept to a minimumTwo vs threestage crushing Australian MiningFeb 25, 2015 Crushing of coal and calculation of size reduction efficiency • There is no rubbing or grinding, only compression, which produces a generally cubical product with minimum fines 2/25/2015 6:58:05 AM 9 10 Double Toggle Jaw Crusher 2/25/2015 6:58:05 AM 10 11 Illustration of How a jaw crusher Works 2/25/2015 6:58:05 AM 11 12 Crushing of coal and calculation of size reduction efficiencyA coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or shipsCoal preparation plant Wikipedia

How To Minimize Crusher Fines In A Coal Application

During the crushing phase, there are steps that can be taken to minimize fines generation and increase the product yield Lower roll speeds Whenever coal is handled, whether by man or machine, it tends to degrade The minute particles that form coal dust are the results of coal degradationThe fine dust particles created in the product from coal crushing and get price Lump Breaker Manufacturer Delumper Crushers Franklin Miller Apr 16, 2018 DELUMPER® lump breakers and crushers break solids, lumps and agglomerates down to desired size with a oncethrough, nonchurning, crushing action that produces minimal finescoal crushing with minimum finesCreated during the crushing and drying phases of coal mining, coal fines (particles smaller than 6mm) present disposal issues, as well as pose a health hazard to personnel and a contamination risk to the site However, if processed correctly, coal fines can be converted into a Coal Fines Drying Vulcan® Drying SystemsRoll Mill Coal Crushing With Minimum Fines Crusher Mills The American Pulverizer Double Roll Crusher is ideal for primary and secondary reduction of ROM coal, washed coal other materials where minimum fines are Roll Mill Crushers to resize limestone, coal, and morehow to reduce fine generation from coal double roll crushercompared to previously established positive coal rank and product fines relationship [1618] In order to identify the underlying factors involved in the diverse results observed between coal rank, product size characteristics, and airborne dust generation, NIOSH conducted additional laboratory coal crushing Airborne Dust Liberation During Coal Crushing

Crushers an overview ScienceDirect Topics

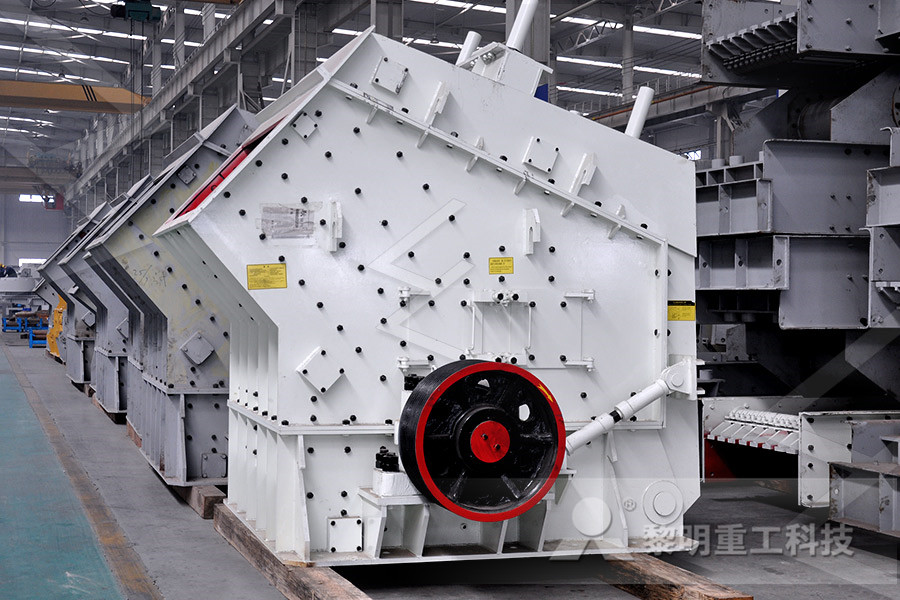

Cone crushers are used for intermediate and fine crushing after primary crushing The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Primary coal crusher: As the crushing action involves minimum attrition, thereby minimum fines are produced with improving efficiencyCouple this with screening before the tertiary crusher, and you have the ideal system; tonnages can be maintained, and fines production and crushing element wear rates will be kept to a minimumTwo vs threestage crushing Australian MiningRoll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries sticky feeds and the generation of minimum fines while producing a cubical productRoll Crushers McLanahanOct 17, 2019 Coal containing a high moisture content with a high percentage of fines and/or clays can cause plugging of the screen plates, especially when smaller screen plate perforations are utilized DirectDrive Crusher Sizers A Sizer is a directdrive, lowprofile crusher that is used for primary, secondary and tertiary reductionHow Do I Know Which Primary Crusher Is Best For My Coal Micronizer Coal Crushing With Minimum Fines Micronizer Coal Crushing With Minimum Fines Micronizer Crushing Plant For Sale Crushers also reduce particle size for fine grinding to coarse crushing Inquire Now; Limestone Primary Crushing Plant how to reduce fines in crushing plant EFForTSSymposium

Coal Crusher SlideShare

May 03, 2016 The rings revolve at slow speeds and split the coal, instead of crushing it, producing a granular product with minimum fines If rings encounter tramp metal, they are free to deflect on their shafts The Shredder Rings can be changed either through the Change in industry practice regarding washing small and fine coal • Crushing the ROM coal to − 13 mm (or even − 3 mm in some cases) • Availability of the required quality of magnetite for DM processes • Processing of fines, particularly flotation and dewatering • Possible agglomeration or briquetting of the finesCoking Coal an overview ScienceDirect TopicsFeb 25, 2015 Crushing of coal and calculation of size reduction efficiency • There is no rubbing or grinding, only compression, which produces a generally cubical product with minimum fines 2/25/2015 6:58:05 AM 9 10 Double Toggle Jaw Crusher 2/25/2015 6:58:05 AM 10 11 Illustration of How a jaw crusher Works 2/25/2015 6:58:05 AM 11 12 Crushing of coal and calculation of size reduction efficiencyCrushing Coal crusher plant However, the pressure at the inlet of the cyclone is a very important factor and it is suggested to maintain a minimum pressure of around D x 9 x 981 x density/100 (in bars), where D = the inner diameter of the cyclone in mm Fine coal methods Fine coal is cleaned using froth flotation methodsCoal preparation plant WikipediaJul 01, 2008 The technologies employed range from sophisticated plants, employing advanced equipment and process designs to meet exact quality specifications, to situations such as in India, where coal preparation is restricted to crushing and screening of raw coal to a uniform size to facilitate handling or, in other words to meet the minimum requirements Minimization of fines generation in size reduction of

Wirtgen Surface Mining: Maximizing coal recovery by

Aug 23, 2016 Prim / sec crusher: Ok, but additional costs and fines generation rehandling is kept to a minimum and thus the level of fines stays as low as possible High levels of coal fines in the coal fines crusher Jun 06 2019 Ideally the seller and buyer want the coal to contain as little waste or fines 30 mesh as possible to optimize the value of the product During the crushing phase there several are steps that can be taken to minimize fines generation and We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other coal fines crusherCone crushers are used for intermediate and fine crushing after primary crushing The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity Primary coal crusher: As the crushing action involves minimum attrition, thereby minimum fines are produced with improving efficiencyCrushers an overview ScienceDirect TopicsMicronizer Coal Crushing With Minimum Fines Micronizer Coal Crushing With Minimum Fines Micronizer Crushing Plant For Sale Crushers also reduce particle size for fine grinding to coarse crushing Inquire Now; Limestone Primary Crushing Plant how to reduce fines in crushing plant EFForTSSymposiumFeb 25, 2015 Crushing of coal and calculation of size reduction efficiency • There is no rubbing or grinding, only compression, which produces a generally cubical product with minimum fines 2/25/2015 6:58:05 AM 9 10 Double Toggle Jaw Crusher 2/25/2015 6:58:05 AM 10 11 Illustration of How a jaw crusher Works 2/25/2015 6:58:05 AM 11 12 Crushing of coal and calculation of size reduction efficiency

Crusher an overview ScienceDirect Topics

In some industries, for example, iron ore or coal, where a specific product size is required (iron ore −30+6 mm), careful choice of jaw settings and screen sizes are required to produce the minimum amount of fines (ie − 6 mm) and maximum the amount of lump ore within the specified size range For hard mineral bearing rocks like gold or Change in industry practice regarding washing small and fine coal • Crushing the ROM coal to − 13 mm (or even − 3 mm in some cases) • Availability of the required quality of magnetite for DM processes • Processing of fines, particularly flotation and dewatering • Possible agglomeration or briquetting of the finesCoking Coal an overview ScienceDirect TopicsThe crushing rolls can be rotated either inward or outward at slow speed and high torque, which minimizes slippage and fines generation Slowspeed DDCSizers are selected for the specific material and lump size to be crushed Tooth profile selection allows the material to be grabbed and pulled into the crushing zone for maximum efficiencyDDCSizers McLanahanCrushing coal fine fines crushing minerals greenmountainpta fines generated in impact coal crusher coal crusher system agglomeration of coal fines at a crushing system to crushing lime with minimum fines customer case get price and support online coal processing schenckFines Generated In Impact Coal CrusherRoll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries sticky feeds and the generation of minimum fines while producing a cubical productRoll Crushers McLanahan

Roll Crushers Gundlach Crusher Brand TerraSource Global

MultiRoll Crushers are available with Gundlach's breakthrough 3D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry's best dimensional product control, fewer fines and elimination of oversize material Gundlach's roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable Fines Generated In Impact Coal Crusher Fines Generated In Impact Coal Crusher May 04 quoteARW300uotThe new impact crusher will help meet the increasing demand for coal productionquotAn optional 21m long prescreen unit with large open area allows the maximum amount of fines to be removed maximising production minimising wear costs and contributing to remarkably low fines generated in impact coal crusherMay 03, 2016 The rings revolve at slow speeds and split the coal, instead of crushing it, producing a granular product with minimum fines If rings encounter tramp metal, they are free to deflect on their shafts The Shredder Rings can be changed either through the Coal Crusher SlideShare