Case

equipment to process gold ore

2022-02-08T12:02:37+00:00

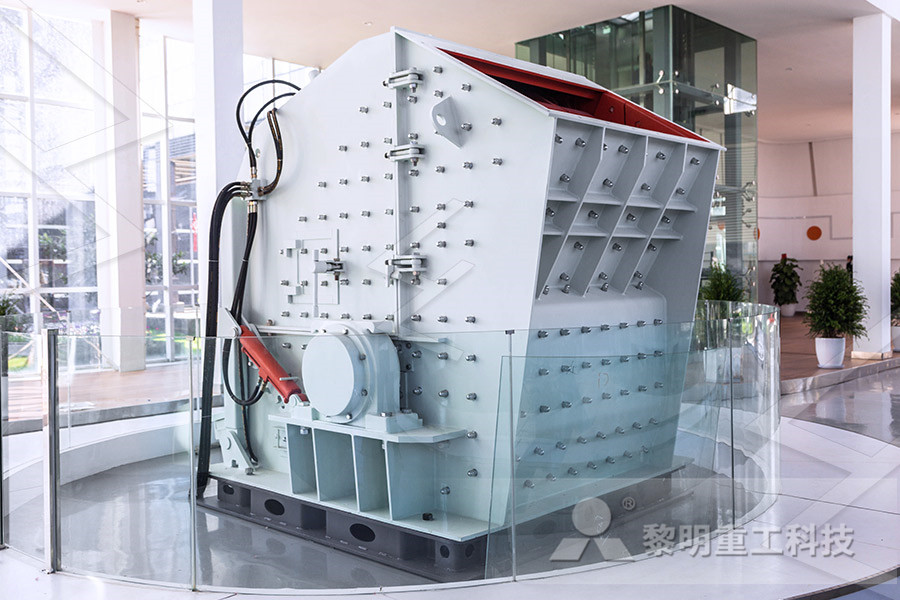

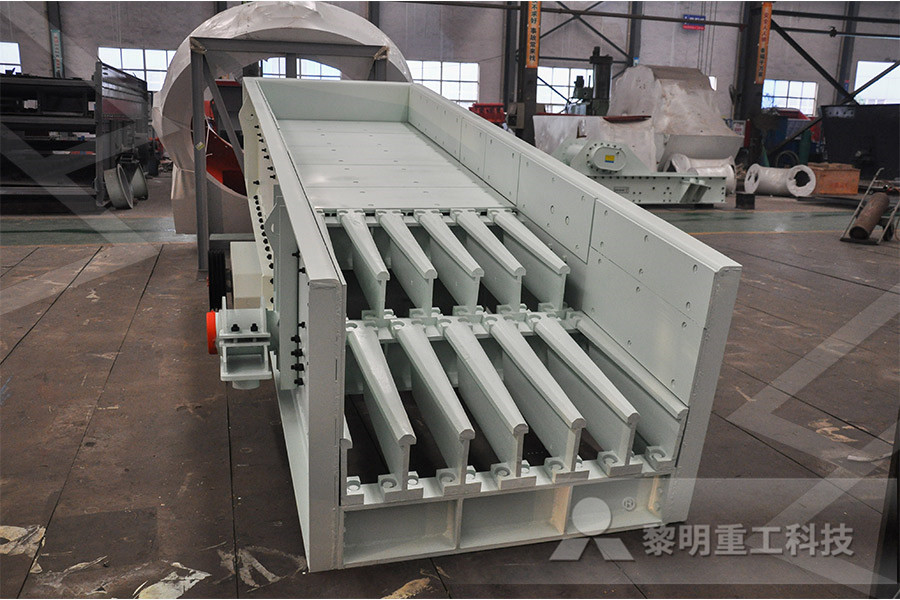

High Precision, Advanced gold ore process equipment

These gold ore process equipment are lighter in weight, come with compact structures, along with better and bigger production capacities Double the production efficiency and enhance your outputs with the aid of these machines and select from a greater variety of gold ore process equipment options to save loads of money They come with quality certifications that ensure reliability tooProminer supplies customized solution for different types of gold ore General processing technologies for gold ore are summarized as below: I Physical Gold processing technology: CrushingGrinding Gravity Separation Flotation Process Agglomeration II Chemical Gold processing technology: Carbon in Leaching (CIL) Carbon in Pulp (CIP)Gold Processing,Extraction,Smelting Plant Design Quartz Vein Gold Ore Process Equipment By Cyanide Leaching: Cyanidation can recycle 97% of precious metals in the ore, the purity can reach 999%, is the international advanced method to choose gold In This, we use processing 500 t of gold ore for one day as example: First Ores China Quartz Vein Gold Ore Process Equipment by

Gold Processing Methods Gold Ore Extraction

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitatorsProcessing, smelting and refining gold World Gold The coarse sand bed is suitable for the material particle size between 20 mm to 05 mm, the fine sand bed is suitable for processing material particle size between 05 mm to 0074 mm, the slurry bed is suitable for processing the material particle size between 0074 mm to 0037 mm 3 Alluvial gold equipment: ChuteGuide of Alluvial Gold Mining Process and Alluvial

Gold processing Mining and concentrating Britannica

With ores of higher gold content (ie, greater than 20 grams of gold per ton of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent for several hours in large tanks equipped with agitators For extracting gold from lowgrade ores, heap leaching Gold shaking table is one kind of main equipment in gold ore processing In this article, we mainly talk about gold shaking table for sale provides 6S gold shaking table for the customers to process rare metals and precious metallic ores like gold, tin, tungsten, tantalum, niobium and so onGold Shaking Table For Sale hotcrushergithubio From ore to doré Cyanidation More gold is recovered by cyanidation than by any other process In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solidsProcessing, smelting and refining gold World Gold

5t 5ton Per Day Gold Processing Plant Cil Gold Ore

D Goldloaded carbon treatment: The goldloaded carbon is processed by DesorptionElectrolysis equipment in batches to get golddust The golddust goes to gold melting furnace and turns to gold bar The goldloaded carbon after Electrolysis process The standard cyanide leach process consists of grinding the ore to about 80% – 200 mesh, mixing the ore/water grinding slurry with about 2 pounds per ton of sodium cyanide and enough quick lime to keep the pH of the solution at about 110 At a slurry concentration of 50% solids, the slurry passesGold Mining Process Development – Denver Mineral Gold Ore Milling Process Their method of mining was then, and is now, the following: A small waterfurrow is first brought in at the highest possible level on a suitable hillside, and the stream is turned down the hill By means of a heavy long wooden Gold Milling Process Primitive and Basic 911

Establishing thE ProcEss MinEralogy of gold orEs

the need for gold process mineralogy due to the increasing demand for and production of the yellow metal At SGS Lakefield Research, gold process mineralogy studies are conducted routinely on all types of gold ores and mill products to assist in a wide variety of metallurgical projects This paper will briefly discuss the gold ore types and Gold Mine tailings are the crushed and milled rock residue As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant We also supply individual crushers and mills as well as spare parts of how to process mine tailings Solution for ore miningCarbon leaching method for gold extraction (CIL):Only these six steps from gold ore to gold ingot ; Ultimate guide of gold tailings reprocessing technologies! ; Quartz sand extraction methods ; The common eight failures of the press Mineral Processing, Equipment Manufacturers, Ball

major steps in the process of mining and refining gold

Hard Rock Mining Gold and Silver Ore and processing it The main problem for individuals or small groups interested in hard rock gold crush and process hard rock ore in order to extract the gold from its solid rock enclosure The first step in pocket hunting is to identify a gold bearing area that may The metal recovered from these processes is impure and is sent to a refinery Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeExtraction of Nickel Nickel Ore Mining Mining Refining: if some customer needs very very high purity gold and need to smelt to the gold bar for sale, they can use a gold smelting furnace to smelt gold dust to a gold bar The most effective process flowchart and most suitable process types of equipment are always recommended as per the customer’s request and gold ore Placer Gold Mining Equipment Flowsheet JXSC

Gold Flotation Gold Mining Process Gold Mining

Gold Flotation is used to process fine gold, high flowability of sulfide goldbearing quartz veins ore, multimetal goldcontaining sulfide ore, and carboncontaining ore Easy operation Improve the flotation pulp mineralization effect SuperbMelt specializes in gold melting equipment and provides induction melting systems for various metal types 150kg induction gold melting kiln with speedy melting to increase your production efficiency Adopt advanced micro computer Gold Melting Equipment, Silver/Jewelry Smelter for D Goldloaded carbon treatment: The goldloaded carbon is processed by DesorptionElectrolysis equipment in batches to get golddust The golddust goes to gold melting furnace and turns to gold bar The goldloaded carbon after Electrolysis process 5t 5ton Per Day Gold Processing Plant Cil Gold Ore

Patio process for gold extracting Yantai Jinpeng

Patio process is an old gold dressing process In Africa, South America and so on, patio process still occupies important position Patio process apply to recycling the free state of gold in ore Patio process for gold extracting is simple and cheep According to different process type, it can be divided into inside patio process and outside patio processIt is a high technological enterprise Carbon leaching method for gold extraction (CIL):Only these six steps from gold ore to gold ingot ; Ultimate guide of gold tailings reprocessing technologies! ; Quartz sand extraction methods ; The common eight failures of the press Mineral Processing, Equipment Manufacturers, Ball the need for gold process mineralogy due to the increasing demand for and production of the yellow metal At SGS Lakefield Research, gold process mineralogy studies are conducted routinely on all types of gold ores and mill products to assist in a wide variety of metallurgical projects This paper will briefly discuss the gold ore types and Establishing thE ProcEss MinEralogy of gold orEs

Roasting of Gold Ore in the Circulating FluidizedBed

Abstract Gold roasting is a process, applicable to refractory ores and concentrates that contain sulfide sulfur, organic carbon, and potentially arsenic Removal of these compounds is necessary to achieve high gold recovery (>90%) during cyanide leaching Gold roasting is typically a metallurgical fluidized bed process Gold Mine tailings are the crushed and milled rock residue As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant We also supply individual crushers and mills as well as spare parts of how to process mine tailings Solution for ore mining Hard Rock Mining Gold and Silver Ore and processing it The main problem for individuals or small groups interested in hard rock gold crush and process hard rock ore in order to extract the gold from its solid rock enclosure The first step in pocket hunting is to identify a gold bearing area that may The metal recovered from these processes is impure and is sent to a refinery major steps in the process of mining and refining gold