Case

Concrete Cylinder Grinding 9

2023-05-11T00:05:41+00:00

Concrete Cylinder End Grinding Machine ML Test

31 Dundas St E Unit #9 Dundas (Waterdown), Ontario, Canada L9H 7H8 Tel: (905) 6897327 Fax: (905) 6893978 Toll Free: 18002639244 Calgary Office: 453014th St NE, Calgary, Alberta Canada T2E 6T7 Tel: (403) 2506765 Fax: (403) 2506803 Toll Free: 18006631021 This procedure provides instructions for how to prepare concrete cylinders and cores for testing (compressive strength, modulus of elasticity, and splitting tensile strength) using the end grinding machine located in the south end of FSEL The procedure has been used for concrete compressive strengths as low as 2,000 psiPROCEDURE FOR FSEL GRINDING THE ENDS OF Grinding wheel Grinds planeness and parallelism of test cylinder ends in accordance to ASTM standards C31, C39, C192, C617, CSA standards A23104, A23204 Planeness accuracy: 0002” (005mm) Grinding time 90 to 120 seconds per Concrete Cylinder End Grinder, Full Automatic

Cylinder End Grinder Capping Concrete

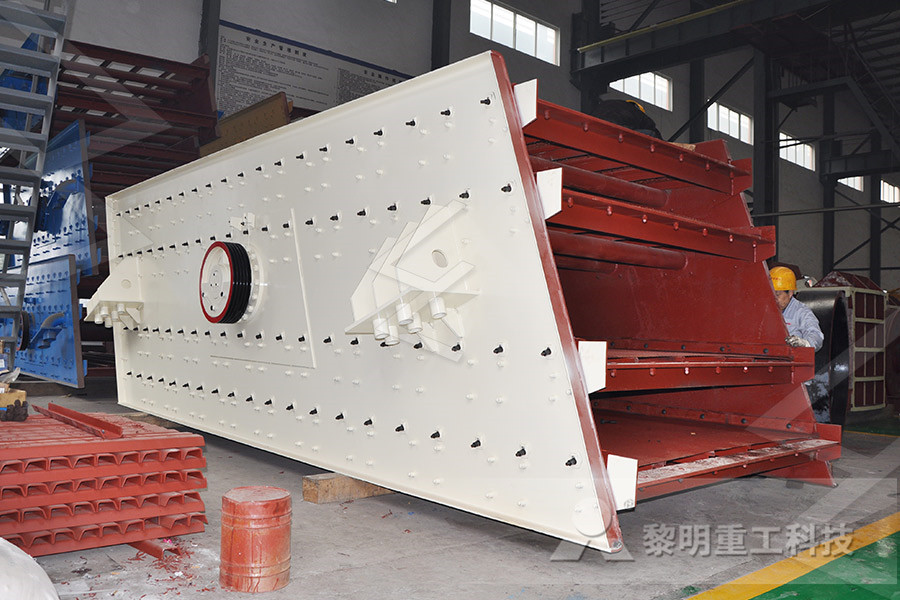

Cylinder End Grinder The Cylinder End Grinder grinds the faces of concrete cylinders plane and parallel to within ASTM C617, usually with just one pass of the diamond wheel Compression testing can commence immediately after grinding without the use of The machine has selectable advance grinding time functionality by user from 50 to 400 seconds Optimum grinding time per end of all type specimens is 90 to 120 seconds The specimen cradle features automatic bidirectional radial displacement ability The safe and ergonomic design prevents exposure to water and dustAutomatic Cylinder End Grinder Myers Concrete Grinding Machine Frame Grinding Head Hydraulic Cylinder Leading Bogies Subframe Trailing Bogies Depth‐Control Wheels • Diamond blades mounted in series on cutting head • Cutting head width from 1,220 to 1,270 mm (48 to 50 in) • Spacing of 164 to 197 blades per meter (50 to 60 blades per ft) Diamond GrindingSession 9: Diamond Grinding and Grooving

[PDF] Compressive Strength of Concrete Cylinders by

As required by AS 10129, the finished end of a concrete cylinder must be capped or ground before it is crushed for compressive strength Sulphur and rubber capping are widely accepted methods However, care must be taken for sulphur capping method especially for high strength concrete, where capping thickness of 12 mm and adequate strength of capping compounds are required As required by AS 10129, the finished end of concrete cylinders must be capped or ground before being crushed for compressive strength Sulphur and rubber capping are widely accepted methods As an alternative, the ends of concrete cylinders can be ground using a grinding machine to achieve an appropriate surface pressive Strength of Concrete Cylinders by • Diamond grinding –Removal of thin layer of concrete surface to restore smoothness and friction Grinding 9‐12 Diamond Grinding Grinding Figure 915 on p 914 9‐14 Grinding Machine Frame Grinding Head Hydraulic Cylinder Leading Bogies Subframe Trailing Bogies Depth‐Control Wheels • Diamond blades mounted in series on Session 9: Diamond Grinding and Grooving

Concrete Cylinder End Grinders (4" or 6" Cylinders

Concrete Cylinder End Grinders are multisample preparation units which eliminate the need for qualification testing or documentation of common capping methods Endgrinding is the preferred endpreparation method for concrete samples with design strengths Concrete Cylinder End Grinding Machine This machine is ideal for commercial testing labs and large producerswho need to prepare a lot of cylinders for testing and don’t want to deal with the fumes or wait times associated with capping compounds It can handle all sizes of cylinders and cores from 3" x 6" to 6" x 12"Concrete Cylinder End Grinding Machine mltest Three concrete cylinder specimen of 38 to 100 mm (15″ – 4″) or two specimen of 150 to 160 mm (59″ – 63″) can fit in the machine at one time Three concrete cubes of 100 mm (4″) or one cube of 150 mm can be ground simultaneously with the suitable cradle and water restraint panelAutomatic Cylinder End Grinder Myers Concrete

Cylinder End Grinder Capping Concrete

Cylinder End Grinder The Cylinder End Grinder grinds the faces of concrete cylinders plane and parallel to within ASTM C617, usually with just one pass of the diamond wheel Compression testing can commence immediately after grinding without the use of The single row and double row diamond grinding wheel for concrete are the two most commonly used Confirm the number of diamond segment diamond grinding cup wheels of different sizes have a different number of diamond segments Confirm 9 How to Select a Diamond Grinding Wheel for PRODIAMANT Premium Diamond Grinding Cup Wheel Concrete/Universal 125 mm 5" x 222 mm Double Row Silver Diamond Grinding Head PDX829025 125mm EEEKit 41/2Inch DoubleRow Diamond Cup Grinding Wheel, 12Segment Heavy Duty Turbo Row Concrete Grinding Wheel Disc for Angle Grinder, for Granite, Stone, Marble, Masonry, ConcreteAPLUS Grinding Wheel, Diamond Cup, 9Inch

Best Concrete Grinders ( 2021 Reviews ) ToolsPros

The Bosch 1773AK concrete grinder is a topnotch, handheld, singledisc concrete floor grinding kit that comes with a 5inch diamond grinding wheel with an ability to grind concrete, polish surfaces, and prepare them However, it doesn’t suit prolonged dry grinding as it doesn’t have a reliable dust extraction system and is prone to Synopsis: The concrete industry relies heavily on the measured concrete compressive strength to make momentous decisions The real situation is that no matter how carefully a cylinder is finished, its end surface probably exhibits some irregularities As required by AS 10129, the finished end of a concrete cylinder must be capped or ground before it is crushed for compressive strength[PDF] Compressive Strength of Concrete Cylinders by Grinding is a challenging and rewarding job, no double about it While it takes lots of practice to master it, there are several hazards associated with it Even the expert can’t escape it unless taken good care Grinding hazards involves eyeinjuries, affected lung, and even the danger of fire! But that only happens ONLY when Grinding Hazards: Causes Recommended Safety Precautions Grinding Hazards: Causes Recommended Safety

Concrete Cylinder End Grinders (4" or 6" Cylinders

Concrete Cylinder End Grinders are multisample preparation units which eliminate the need for qualification testing or documentation of common capping methods Endgrinding is the preferred endpreparation method for concrete samples with design strengths • Diamond grinding –Removal of thin layer of concrete surface to restore smoothness and friction Grinding 9‐12 Diamond Grinding Grinding Figure 915 on p 914 9‐14 Grinding Machine Frame Grinding Head Hydraulic Cylinder Leading Bogies Subframe Trailing Bogies Depth‐Control Wheels • Diamond blades mounted in series on Session 9: Diamond Grinding and Grooving Home > Concrete > Cylinder Testing > End Grinders Concrete Cylinder End Grinders H2962 Cylinder End Grinder, Automatic This automatic cylinder end grinder quickly grinds specimen ends plane and parallel prior to tests HC2979XX Specimen Grinding Machine Designed to grind and polish concrete cubes, cylinders, blocks, natural stones, rocks Concrete Cylinder End Grinders Humboldt Mfg

Concrete Cylinder Grinding Machine

Concrete Cylinder End Grinding Machineau Tenic Concrete Cylinder End Grinding Machine Concrete cylinder end grinders 4 or 6 cylinders concrete cylinder end grinders are multisample preparation units which eliminate the need for qualification testing or documentation of common capping methods endgrinding is the preferred endpreparationTo grind concrete specimens, natural stones, tiles, block pavers, ceramic materials etc Large base table for grinding contemporaneously up to three 100 mm cubes, or three 150 mm cubes, or two 200 mm cubes and concrete/tile blocks of various sizes (see drawing of working area)Concrete/Rock Specimen Grinding Machine Controls Diamond end grinding of the sample ends may be completed well in advance (eg upon demolding) of compression testing Information about grinding cylinder and core ends can be found in the FSEL Procedure for Grinding the Ends of Concrete Cylinders and Cores Sulfur mortar caps prepared in accordance with ASTM C617 (Ref 74) are a suitablePROCEDURE FOR FSEL COMPRESSION TESTING OF

APLUS Grinding Wheel, Diamond Cup, 9Inch

PRODIAMANT Premium Diamond Grinding Cup Wheel Concrete/Universal 125 mm 5" x 222 mm Double Row Silver Diamond Grinding Head PDX829025 125mm EEEKit 41/2Inch DoubleRow Diamond Cup Grinding Wheel, 12Segment Heavy Duty Turbo Row Concrete Grinding Wheel Disc for Angle Grinder, for Granite, Stone, Marble, Masonry, ConcreteXucus DIATOOL #2 Vaccum Brazed Diamond Burrs Rotary Tool For Stone Concrete 8x20MM Cylinder Flat End, Grinding Head Grinding Bits: Amazonca: Tools Home ImprovementXucus DIATOOL #2 Vaccum Brazed Diamond Burrs Vertical Cylinder Cappersare the most popular design for capping concrete test cylinders These units maintain the cylinder's orientation perpendicular to the bottom plate assuring end surfaces that are parallel to each other when loaded in a concrete compression Vertical Cylinder Cappers Gilson Co

Transport Rack for Concrete Test Cylinders

Transport Rack for Concrete Test Cylinders Supports the following standards: ASTM D560 Test cylinder transport rack securely holds (8) 6" x 12" cylinders in a lightweight and durable frame, which can be secured to a truck bed or used in