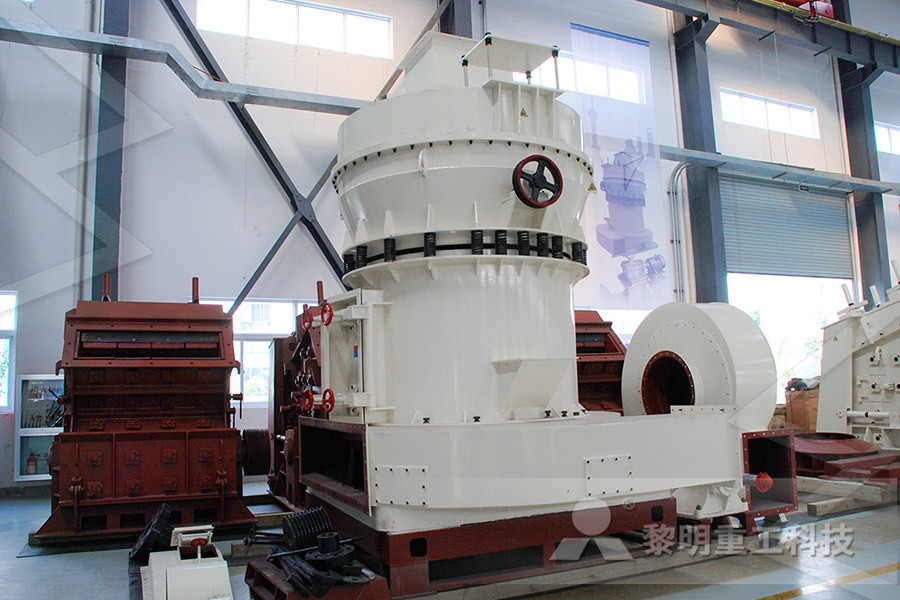

Case

simple structure rolling mill equipment

2023-12-13T23:12:53+00:00

Rolling Mills – Fenn Torin FENN Metal Forming

TwoHigh: Generally, a 2HI mill is used for hot or cold breakdown and finishing of bar, sheet or strip A wide range of sizes with separating force capacities from 10,000 lbs (453 MT) to over 3,000,000 lbs (1360 MT) are available ThreeHigh: A 3HI mill is an economic milling solution for the breakdown of rod and ingot FourHigh: A 4HI mill may be used for finish rolling of thin gauge 1 Introduction Rolling Mill gear consists of drum gear, bevel gear, circular gear, ect Our company can supply all varieties spot models Bevel gears: are gears where the axes China Rolling Mill, Rolling Mill Manufacturers, The fourroll hydraulic precision rolling mill is widely used for rolling medium widestrip mill due to its simple structure, convenient Fourroll Precision Hydrau The overall frame structure of the 20high rolling mill has the advantages of great rigidity, bearing the Strip Rolling Mill Cold Rolling Mill Supplier Hani Tech

Products Archive Bar Wire Rod Rolling Mill

The fourroll hydraulic precision rolling mill is widely used for rolling medium widestrip mill due to its simple structure, convenient Fourroll Precision Hydrau Industrial furnaces are thermal equipment for heating materials or workpieces by burning heat or The equipment supplied by Kathuria included two 230 neck stand and six 200 neck stands Housingless Horizontal Mill Stands with high rigidity and flexibility, along with Section and Side changing Roll changing was pretty simple and took only 20 to 25 minutes with section and grade rigidityKathuria Rollmill Inspiring Rolling Mill Solutions At present, most of the newlybuilt and inuse rolling mills in the world are mostly continuous small rolling mills Rebar production process: (scrap steel melting furnace ,Continuous casting machine,billet heating furnace)step heating furnace→roughing mill→medium mill→finishing mill→water cooling device→cooling bed→cold shear→automatic counting device→bundling machine→cutting material rackRebar Rolling Mill Machine Steel Rolling Mill Machine

Mini Mills from a single source Primetals Technologies

Primetals Technologies is one of the leading companies in Mini Mill technologies, offering mechanical and electrical equipment, engineering, automation, and process technology from a single source By completely coordinating all complex technical, metallurgical, Safety in Rolling Mills Worldwide, as the rolling speeds are increasing, greater emphasis is being placed on the aspects of safety while designing the mill equipment as well as during the finalization of the mill layouts Providing high importance to safety is in the best interest of the designers, manufacturers and the users of the rolling Safety in Rolling Mills – IspatGuru The 'Global and Chinese Rolling Mill Equipment Industry, 20122022 Market Research Report' is a professional and indepth study on the current state of the global Rolling Mill Equipment industry with a focus on the Chinese marketGlobal and Chinese Rolling Mill Equipment Industry

Rebar Rolling Mill Machine Steel Rolling Mill Machine

Bar Steel Rolling Mill Equipment; Visual pressure state, according to different rolling process adjust the corresponding pressure, simple operation, easy to observe; Cooling bed is mainly used for slow natural cooling plate line after rolling In the structure steel production line, cooling bed also has a precurved function to prevent Rolling Mill (Rolling Machine) Draw Benches (Drawing Machines) flat bar, Trail, Ubar, Hbeam, angle etcIt is popular with its advantages of simple structure, cheap price and easy control We will make special proposal for customers as per their detail requirementOur cold drawing machine are exported to Russia, Mexico, India, Turkey Draw Bench Machine Rolling Mill, Rolling Machine What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform The concept is similar to the rolling of dough Rolling What Is A Rolling Mill? Metal Processing Machinery

Basics of Rolling and Rolling Mills – IspatGuru

Fig 4 Roll configurations in rolling mills Twohigh mill roll configuration – This is the most commonly used rolling mill configuration In this configuration, there are two horizontally mounted rolls The rolling mill motor drives either both rolls (top and MINI MILL TECHNOLOGIES Technology, mechanical engineering, automation, and electrical engineering from a single source – for maximum overall plant performance Our Mini Mills work according to two simple principles: the highest quality equipment and Mini Mills from a single source Primetals Technologies MetalRolling Processes and Equipment Rolling is the process of reducing the thickness or changing the fourhigh rolling mill showing various features The stiffness of the housing, the rolls, and converted to a wrought structure by hot working Flat Rolling Practice The initial rolling steps (breaking down) of the material typically is Ch 13 uohedusa

Steel bars and wire rods from JFE

Billet rough rolling mill Billet finishing rolling mill Continuous casting equipment Ingot casting machine *1: Bloom dimensions: 300 mm (thickness) × 400 mm (width), and 400 mm (thickness) × 560 mm (width) *2: Bloom dimensions: 310 mm (thickness) × 400 mm (width) 16 to 90mm 55 to 18mm 17 to 120mm 167 to 52mm Round bar Square barRolling Circles The circle rolling is the main process of product forming, which is divided into one feed and multifeed process The number of feed times depends on the process (such as the cold roll is not allowed to exceed the allowable maximum deformation rate) and the equipment 3 Roll Bending Machine (Working Principle and The rolling process is shown in Fig 21: Rolling is done both hot and cold It is accomplishes in rolling mills A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etcRolling of Metals: Process and Principles (With Diagram)

Types of Robots Based on Configuration Plant

Rolling Mill Machinery Equipment Farm Machinery Robots are mostly classified into five major configurations based on their mechanical structure They are: An Articulated robot can be defined as a robot with rotary joint and these robots can range from simple Hydraulic Rolling Machine Sheet Metal Rolling W12nc 12mm FOB Price: US $ 150500368800 / Set Min Order: 1 Set W12NC 4roller rolling machine Introduce: The machine adopts the fourroller structure with the upper roller as the main drive The equipment China Rolling Machine, Rolling Machine What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform The concept is similar to the rolling of dough Rolling What Is A Rolling Mill? Metal Processing Machinery

Steel Rolling Mill Plants Manufacturers India

SMW have a leading roll in designing, manufacturing erection of all type tmt, bar, section structure, rail strips rolling mill plants ABOUT US Shivam Mechanical Works is an ISO 9001:2000 Certified Company, engaged in production and supply of steel rerolling plants in different types and capacitiesOur company rolling mill gear box structure featuresnanjing jinxin transmission equipment co LTDGear box type: all the gear boxes of horizontal rolling mill are divided horizontally, and the transmission gears of all levels are arranged as far as possible at the dividing surface of the gear boOur company rolling mill gear box structure features The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics Features: 1 Large application range, simple structure Ball Mill Machine

Vibrating Conveyor manufacturer Daesung

This enables complete airtight structure so as to prevent any powder from flying in the air This is enables to easy maintenance with simple structure and very small area of rolling and wearing This enables works such as drying, cooling, dehydration, selection, John G Lenard, in Primer on Flat Rolling (Second Edition), 2014 35 Friction and Wear Work rolls in hot strip mills wear due to friction between the roll surface and hot strip (Backup rolls wear as well, but under pressure with elastic deformation, the friction is much less, except for the high work roll roughness in the last stand of a sheet rolling tandem cold mill)Hot Strip Mill an overview ScienceDirect Topics Working Principle of Rolling Process: The rolling process is a metal forming process, in which stock of the material is passed between one or more pairs of rollers in order to reduce and to maintain the uniform thickness This process is mainly focused on the crosssection of the ingot or the metal which is formingRolling Process: Working, Application, Defects, Type of

Cold Rolling process overview EngineeringClicks

In simple terms, cold rolling is an industrial process used to change the material properties of sheets or strips of metal The metal is fed between two rollers which compresses it The resulting mechanical properties vary, depending on how much strain is applied The main benefits of cold rolling SERVODAY GROUP BUSINESS Here we look at some business endeavors that will help carve out our next stage of growth Seed and Oil Processing Plants Seed and Oil Processing Plants Oil Milling Plants from 50 TPD, Solvent Extraction Plant from 100 TPD, Edible and NonEdible Oil Refining Plant from 10 TPD for Groundnut Rapeseed Cottonseed Sunflower Soya Castor Neem Macadamia SERVODAY GROUP BUSINESS Here we look at some