Case

feldspar flotation exports feldspar flotation feldspar

2020-02-06T21:02:53+00:00

Feldspar Beneficiation Flotation Process 911

Feldspar Flotation All flotation is carried out in acid circuits, either with sulphuric acid or hydrofluoric acid both of which are highly corrosive to metal parts For this reason it is necessary to use flotation machines with wooden tanks, partitions, FLOTATION PROCESS FOR RECOVERING FELDSPAR FROM A FELDSPAR … A flotation process for recovering feldspar from a feldspar containing feed material comprising the following steps: 1 forming an aqueous suspension of a feldspar containing feed material in the absence of hydrofluoric acid wherein the suspension comprises from 0004 to 03 wt of a flotation reagent Feldspar Flotation Process In Uganda S K Cationic flotation of feldspar (amine + HF) in presence of NaCl was conducted by CengizDemir of Turkey in 2010 to separate both Na and Kfeldspar [3] NaCl addition controls amine adsorption on sodium feldspar through adsorption of Na+ ions onto the mineral surface [3] The use of NaCl addition in flotation was found to increase the KfeldsparDifferential Flotation of Some Egyptian Feldspars for

Selective flotation of Kfeldspar from Nafeldspar in

A newly developed alkaline flotation process for the separation of Kfeldspar from Nafeldspar • A Kfeldspar concentrate of 143% K 2 O at good recovery was produced from a pegmatite Fluorine desorption is assumed to be an important part of the separation mechanism Table of ContentsConventional Feldspar Flotation Using HFThe NonHf Feldspar Flotation MethodProcess DescriptionExperimental Results Feldspathic deposits occur widely throughout the United States, but North Carolina, California, Connecticut and South Carolina accounted for over 80% of the total domestic feldspar output for the year 1973 Pegmatites and granites constitute the major feldspar Selective Flotation Separation of Feldspar in Non In order to verify the effect of HF pretreatment on the flotation separation of feldspar and quartz, bench scale flotation tests were carried out using 300 g minerals in a laboratory flotation cell with a volume of 1 L DDA collector (100 g/t) was added and conditioned further for 3 min, the pulp was then floated for 3 min After the flotation of feldspar, the concentrates and tailings were filtered, washed and dried to analyze the flotation recovery of feldspar Developing Effective Separation of Feldspar and

Mitigating the negative effects of feldspar slime on

The influence of feldspar slime on the flotation of spodumene in the NaOL and NaOL/DDA (mole ratio is 9/1) systems was investigated by microflotation at pH 80–85 The effect of feldspar slime dosage on spodumene recovery is shown in Fig 4 The spodumene recovery decreased with the increase of feldspar slime, whether it is in the NaOL The general circuit for commercial separation of feldspar consists of three sequential stages of flotation [ 5, 7, 10, 11, 12, 13, 14, 15, 16, 17 ] To remove the micaceous Effects of Ultrasound on Desliming Prior to Feldspar Feldspar Flotation Process An amine collector that floats off and removes mica is utilized in the very first Crushers flotation step Also, sulfuric acid, pine oil, and fuel oil are extra After the feed is dewatered in a very classifier or cyclone to remove reagents, sulfuric acid is added to lower the pHBread Dolomite Crusher Plant: feldspar quarry

Upgrading titanium bearing Nafeldspar by flotation

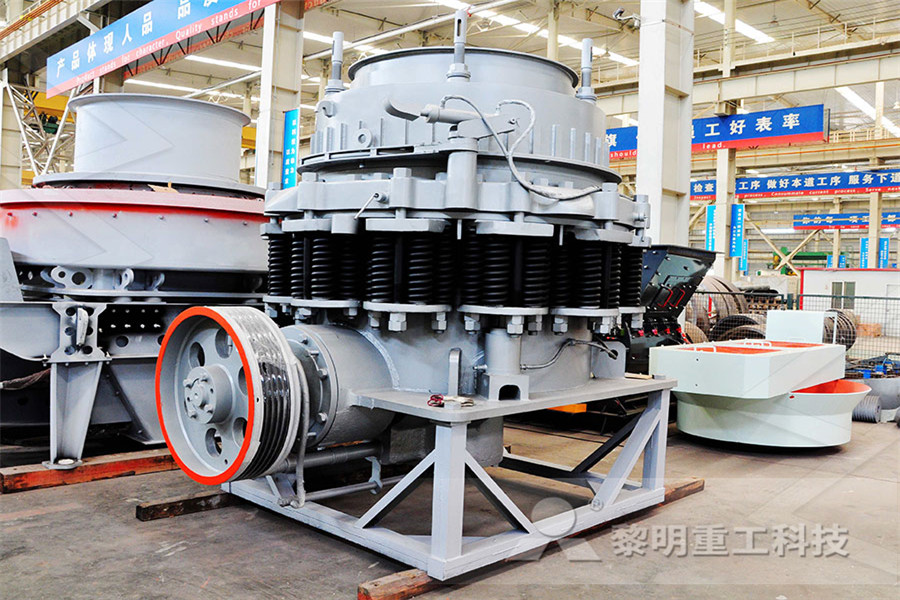

As a result cleaner feldspar concentrates, without loss of feldspar into titanium rich flotation products, were obtained It is believed that the superiority of oleate is a natural outcome of its chemisorption onto oxide minerals as compared to physical adsorption of potash feldspar Good results of feldspar flotation was obtained for granite compared to granodiorite They also explained that a coarser grain is more difficult to float than a finer one, and Kfeldspar is easier to float than plagioclase [9] In this study, cationic flotation has been studied as a function of NaCl concentration in HF medium toSELECTIVE SEPARATION OF Na AND KFELDSPAR FROM flotation process foam feldspar iso certificate flotation machine for feldspar flotation A froth flotation process is used for most feldspar ore beneficiation Figure 11271 shows a process flow diagram of the flotation process The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less feldspar flotation feldspar gimwierzawiceedupl

FLOTATION SEPARATION OF FELDSPAR

1 A froth flotation process for separating feldspar from quartzfeldspar sands ore consisting essentially of the steps of subdividing said ore to produce at least a fraction having a particle size less than about 1 mm, collecting said fraction and washing the same with water to effect desliming, introducing the washed fraction at a solid concentration of about 2030 wt percent into an aqueous of feldspar flotation has been described at length by Rattanakawin (2015) 23 Evaluation The finished float product was weighed, sampled, analyzed by X ray fluorescence, and cone fired respectively Evaluation of the flotation was done using the yield of feldspar and its chemical composition, cone shrinkage, fired color, and Froth flotation of mixed feldspar rdopsuacth Feldspar Flotation Process An amine collector that floats off and removes mica is utilized in the very first Crushers flotation step Also, sulfuric acid, pine oil, and fuel oil are extra After the feed is dewatered in a very classifier or cyclone to remove reagents, sulfuric acid is added to lower the pHBread Dolomite Crusher Plant: feldspar quarry

Effects of Ultrasound on Desliming Prior to Feldspar

In this study, the effects of ultrasound on removal of impurities from raw feldspar were investigated by testing with a newly developed flotation cell with various frequency and power intensities prior to multistage feldspar flotation Particularly, the quality of feldspar 2Includes handcobbed feldspar, flotationconcentrate feldspar, feldspar in feldsparquartz mixtures, and aplite; for use predominantly in the production of ceramics and glass, may differ from sales in table 4 3Rounded to two significant digits to avoid Feldspar and Nepheline Synenite (Advance Release)Potassium feldspar and quartz are all silicate minerals with frame structure,and have the similar crystal structure and physicochemical properties Therefore, flotation has become the main method to separate potassium feldspar from quartz The separation of potassium feldspar from quartz with anion and cation mixed collector was studied in the paperStudy on Flotation Mechanism of Separation of

Effects of Ultrasound on Desliming Prior to Feldspar

In this study, the effects of ultrasound on removal of impurities from raw feldspar were investigated by testing with a newly developed flotation cell with various frequency and power intensities prior to multistage feldspar flotation Particularly, the quality of feldspar What is claimed is: 1 A hydrochloric acid froth flotation process for separating feldspar from an ore containing feldspar and siliceous sand, which comprises finely dividing said ore into fine particles, suspending said particles in an aqueous solution of hydrochloric acid, adding to said suspension a flotation reagent composed of a petroleum sulfonate and an Nhigher alkylalkylenediamine Hydrochloric acid flotation process for separating potash feldspar Good results of feldspar flotation was obtained for granite compared to granodiorite They also explained that a coarser grain is more difficult to float than a finer one, and Kfeldspar is easier to float than plagioclase [9] In this study, cationic flotation has been studied as a function of NaCl concentration in HF medium toSELECTIVE SEPARATION OF Na AND KFELDSPAR FROM

BRITISH GEOLOGICAL SURVEY Mineralogy Petrology

for froth flotation The Thai feldspar fines were sized to 500 to 106/lm (Figure 3) Froth flotation was carried out to produce feldspar concentrates using a twostage process to remove the mica and quartz present in the samples (Appendix A) The flotation was carried out in a pyrex cell using a Denver D12 Laboratory flotation machine FLOTATION SEPARATION OF FELDSPAR KATAYANAGI A,JA 1 A froth flotation process for separating feldspar from quartzfeldspar sands ore consisting essentially of the steps of subdividing said ore to produce at least a fraction having a particle size less than about 1 mm collecting said fraction and washing the same with water to effect desliming introducing the washed fraction at a Feldspar Flotation Process In Uganda S K eEstimated ~Preliminary !Revised ' Includes bandcobbed feldspar, flotation concentrate feldspar, and feldspar in feldsparsilica mixtures; includes potash feldspar (8% K20 or higher) 2Production plus imports minus exportsEcology and Natural Resources: Minerals yearbook

Developing Effective Separation of Feldspar and

The effect of hydrofluoric acid (HF) pretreatment on flotation of feldspar and quartz using dodecylamine (DDA) as collector was investigated by microflotation, zeta potential, pyrene fluorescence spectroscopy, attenuated total reflection flourier transformed infrared spectroscopy (ATRFTIR), scanning electron microscope (SEM), Xray photoelectron spectroscopy (XPS) and bench scale flotationAuthors: Su Juan Yuan, Zhi Yong Shen, Xiao Long Lu Abstract: The lowgrade feldspar from kyanite tailings were studied through the magnetic Antiflotation purification method The ore grade of iron was decraded from 098% to 009% and e the various factors in the test was studied 764Beneficiation of Feldspar from Yozgat Region Granites Feldspar Introduction Feldspar is a basic raw material used in glass and ceramic industries In a significant proportion of feldspar ores, Nafeldspar (albite, NaAlSi3O8) and Kfeldspar (KA1Si3O8 microcline or orthoclase) exist in the same matrix The basic feldspar Feldspar IntroductionFeldspar an overview What is

Study on Flotation Mechanism of Separation of

Potassium feldspar and quartz are all silicate minerals with frame structure,and have the similar crystal structure and physicochemical properties Therefore, flotation has become the main method to separate potassium feldspar from quartz The separation of potassium feldspar from quartz with anion and cation mixed collector was studied in the paperTested alkali sodium potassium feldspar is characterized by low sintering temperature (1190 °C) during fast firing (heating rate 10 °C/min) During the sintering process, feldspar gradually disappears in phases first of all potassium feldspar (microcline), sodium feldspar (albite) we can find in the fired body at firing temperature 1180 °C 109Selective Separation of Sodium and Potassium [8] O Kangal and A Guney: Beneficiation of Low Grade Feldspar Using Free Jet Flotation, Mineral Processing and Extractive Metallurgy Review, Volume 23, Numbers 34, July/December (2002), pp129140 DOI: 101080/895Pilot Scale Tests for Evaluation of Feldspar Tailings for