Case

ball mill type of a mill iron ore in gold milling

2021-12-01T13:12:52+00:00

ball mill type of a mill iron ore in gold milling

Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ores, as well can be configured to fit various types of machines for several appli ions like mining technologies, materials handling and mineral processing 123 Ball millball mills in iron ore mines northpudukkadchurch solutions for gold ore grinding mill solutions for gold ore grinding mill VETURA Heavy solutions for gold ore grinding mill,Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration gravity or flotation or ce varies depending upon the type of ore and the amount of r「ball mill for iron ore mineral making」 Mining Ore Iron Tin Manganese Lead Aluminum Powder Grinding Gold Copper Ball Mill Machine Types of Ball Mill Introduction: Ball Mill is a key equipment to China Mining Ore Iron Tin Manganese Lead

China Gold Mining Mineral Processing Machine Gold

Gold Mining Mineral Processing Machine Gold Grinding Milling Ball Mill for Iron Ore picture from Yantai Huize Mining Engineering Co, Ltd view photo of Ball Mill, Gypsum Powder Machine, Metallurgy MachineryContact China Suppliers for More Products and PriceTop Quality Wet Type Grate Ball Mill, Wet Ball Mill for Iron/Copper Ore Milling picture from Zhengzhou Effort Trading Co, Ltd view photo of Mineral Ball Mill, Gold Ore Milling, Gold Ore Ball MillContact China Suppliers for More Products and PriceChina Top Quality Wet Type Grate Ball Mill, Wet Ball Bulkbuy Top Quality Ball Mill Mining Application for Gold/Iron/Copper/Silver Ore Milling price comparison, get China Top Quality Ball Mill Mining Application for Gold/Iron/Copper/Silver Ore Milling price comparison from Mineral Ball Mill, Gold Ore Milling manufacturers suppliers on Video Channel of MadeinChina Top Quality Ball Mill Mining Application for Gold/Iron

are iron balls from a gold ore ball mill potentially

Occurance extraction of metal SlideShare Apr , the powdered ore is then taken out through a screen by a stream of water fig jaw crusher module occurrence and extraction of metals notes chemistry of elementspulverization can also be carried out in a ball mill the crushed ore is taken in a steel cylinder containing iron balls the cylinder is set into revolving motionBall mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclonesBall Mill an overview ScienceDirect Topics 1 Introduction Iron ore plays an important role in industrial raw materials worldwide Nearly 975% of iron ore resources, including siderite, limonite, and oolitic hematite, etc are typically lowgrade iron ores and difficult to develop in China []As the Chinese economy develops, the demands for steel products grow, and the refractory iron ore resources will be gradually exploited in the Impact of ball filling rate and stirrer tip speed on

ball mill type of a mill iron ore in gold milling

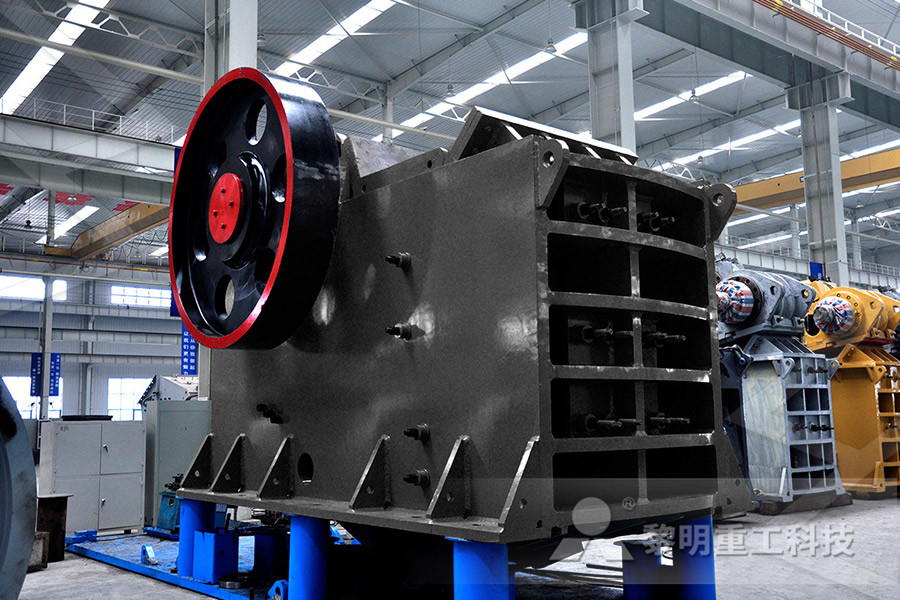

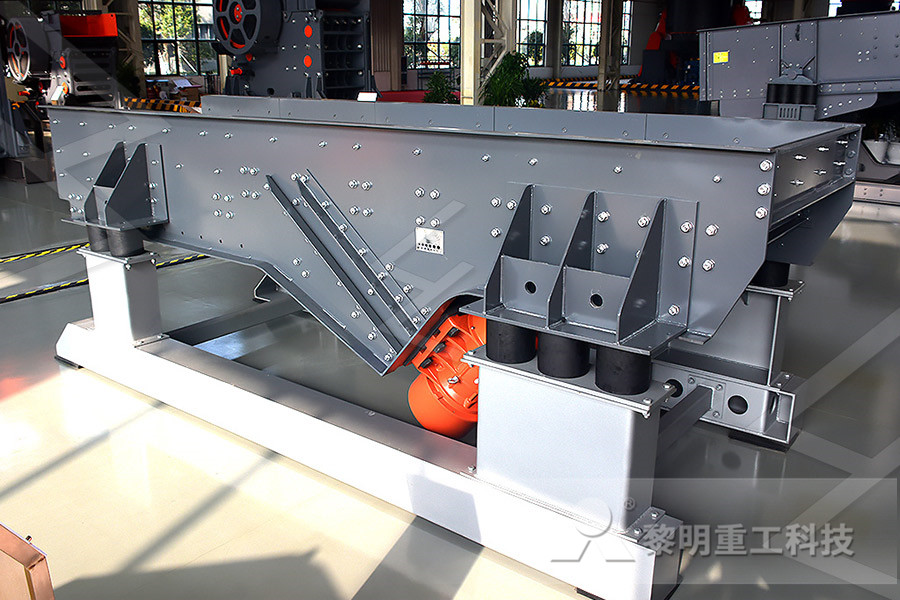

ball mill type of a mill iron ore in gold milling Mill grinding Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processes There are many different types of mills and many types of materials processed in them Mineral Ball Mill, Gold Ore Milling, Gold Ore Ball Mill manufacturer / supplier in China, offering Top Quality Ball Mill Mining Application for Gold/Iron/Copper/Silver Ore Milling, Good Performance Linear Vibrating Screen for Quartz Sand, Mine Powder Stone Powder Separating Linear Vibrating Screen, Mesh Sieve Linear Vibration Screen and so onTop Quality Ball Mill Mining Application for Gold/Iron In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical Ball Mills 911 Metallurgist

Ball Mill for Sale Grinding Machine JXSC Mining

Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being 【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling Ball Mills Industry Grinder for Mineral Processing Ball mill Application: It is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal beneficiation and glass and ceramics industries Material: Iron ore, slag, copper ore, silver ore, galena and other materials The ball mill Ball millHenan Hongji Mine Machinery Co, Ltd

Corrosion During Ore Grinding 911 Metallurgist

Corrosion Rate Measurements in an Iron Ore Mill Pea Ridge Iron Ore Co is a subsidiary of St Joe Minerals Corp and operates the only US underground iron ore mine, about 12 miles south of Sullivan, MO The mine has 196 million st of proved reserves of massive magnetite The ore milling circuit consists of a rod mill followed by a ball mill in series Crusher product (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball mill discharges to a sump where water isGrinding control strategy on the conventional milling The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore Grinding experiments were conducted according to Bond’s standard test procedure []For each iron ore sample, the RT taken to produce 250% circulating load in the BBM was measured by a new methodInvestigation on Iron Ore Grinding based on Particle

What is a Rod Mill? (with picture) InfoBloom

An ore charge is added to the drum, and as it rotates, friction between the tumbling rods breaks the ore down into finer particles Although similar in operation, a rod mill is often more effective than a ball mill as it requires lower rotational speeds and less steel to Ball Mill for Grinding Iron Ore, Gold Ore Ball Mill, Stone Mill Grinder manufacturer / supplier in China, offering Hengxing BrandGold Ore Grinding Mill /Iron Ore Ball Mill/Chromite Ore Ball Mill Dia24X45m, 3050t/Hr 2100*3000 Good Quality Rod Mill Machine for Mining Industry, Ore Rod Mill Machine, Stone Quarry Plant Mutideck Vibrating Screen 「ball crusher mill for grinding gold iron ore」China Reliable Quality Small Ball Mill Used for Gold Ore Milling, Find details about China Small Ball Mill, Gold Ore Milling from Reliable Quality Small Ball Mill Used for Gold Ore Milling Reliable Quality Small Ball Mill Used for Gold Ore Milling

Ball Mills Industry Grinder for Mineral Processing

【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling home; ball mill ore gold grinder; ball mill ore gold grinder Sourcing Guide for Gold Ore Ball Mill China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to ball mill milling machine grinding machineball mill ore gold grinder pixelhaschergeradeMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Gold extraction QueensMineDesignWiki

Ball Mill Ball mills can operate in either wet or dry conditions They are advantageous because they can achieve a very fine particle product size (refer to Table 1) Generally ball mills are utilized after an initial material crushing or grinding has occurred Thus, a disadvantage of the ball mill is that the feed size must already be smallThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics The advantages and disadvantages of ball mills 092120; 723 Views; icon 0; The advantages and disadvantages of ball mills Because the method used to grind the fine material in the beneficiation equipment was an early mine mill, and later developed into a ball millNowadays, there is a finer with a larger output, and the speed of replacement is very fastThe advantages and disadvantages of ball mills

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill Type of milling process and operational parameters SAG and ball mills grind material through different actions and are usually applied in different stages of the process SAG mills usually have a larger diameter than length and are used to reduce large feed size ore (typically ~300mm) down to ~3mm, often for further grinding in a secondary processKey considerations when selecting a mill lining system