Case

gold ore processing zimbabwe.html

2021-01-11T14:01:52+00:00

Gold Ore Processing Plant in ZimbabweFTM Machinery

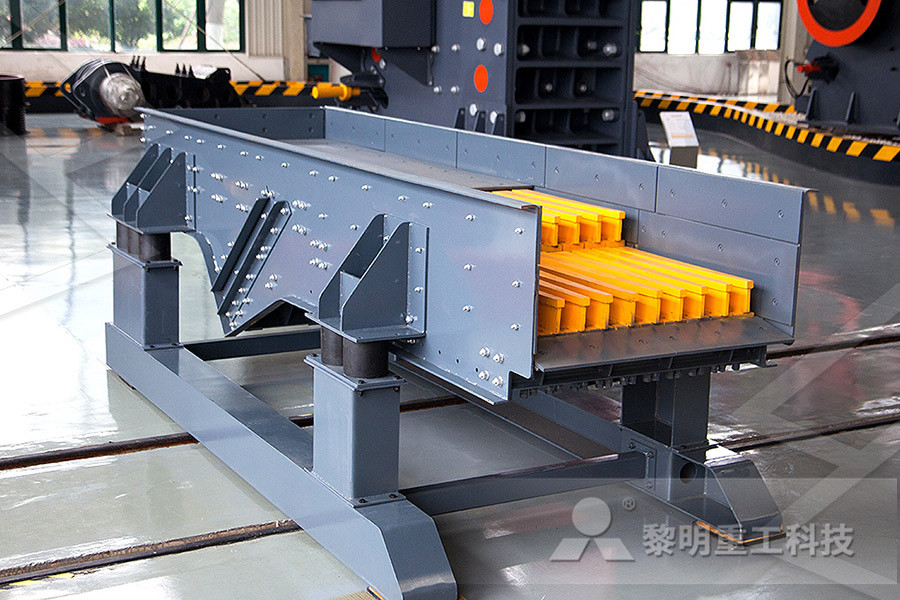

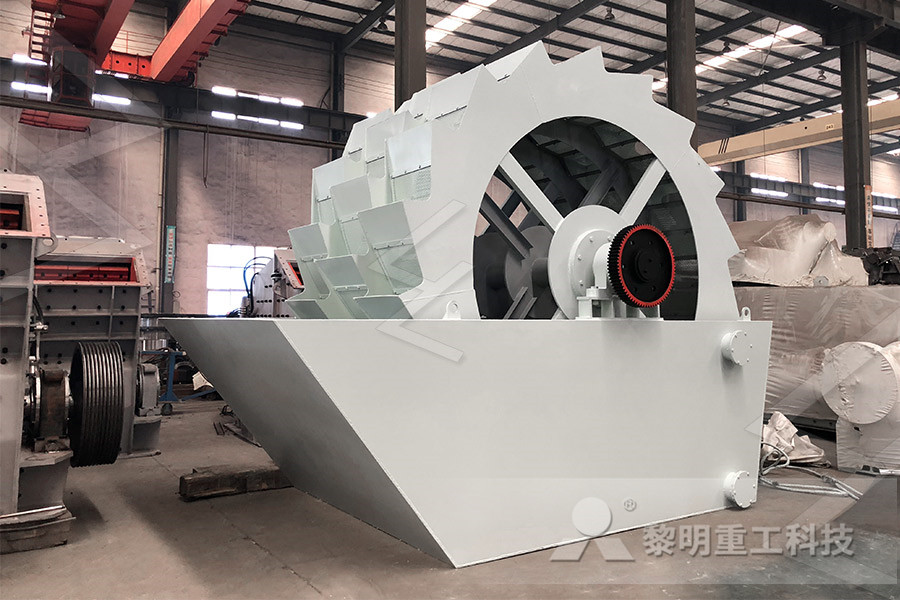

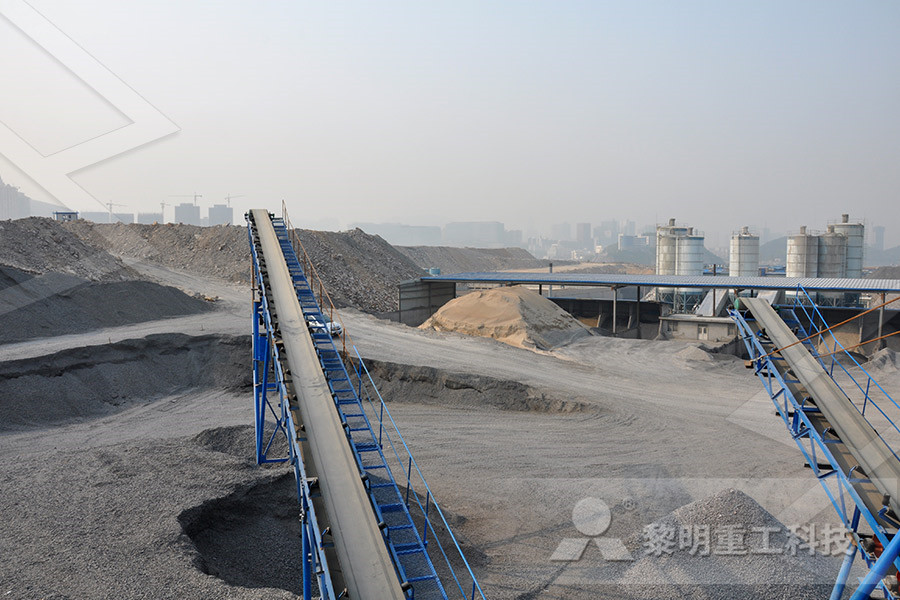

This has made Zimbabwe an important source of gold for many major mining companies across the globe Material: Gold Ore Process: The first section is to crush gold ore stone Gold ores are crushed into small size by jaw crusher as the primary crusher The gold ores with samll size are fed into the ball mill and then to spiral classifierThis has made Zimbabwe an important source of gold for many major mining companies across the globe Material: Gold Ore Process: The first section is to crush gold ore stone Gold ores are crushed into small size by jaw crusher as the primary crusher The gold ores with samll size are fed into the ball mill and then to spiral classifierGold Ore Processing Plant in Zimbabwe Zhongde Heavy The gold ore processing plant and processing technology mainly includes three processes: crushing, milling and beneficiation Our company's gold ore processing plant has the characteristics of high degree of automation, high breaking rate, low operating cost, energy saving and environmental protection, and fine grain sizeGold Ore Processing Plant In Zimbabwe Mining Production Process: the gold ores firstly need to be crushed into small particle size and then they will be sent into ball mill for further grindingThe ore powder will be sent into spiral classifier for grading,and then it will be sent into flotation machine for recovery and enrichmentAfter flotation separation, the ores Gold Ore Processing Plant in ZimbabweChina Mining Ore processing is a 24 hour operation Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along Ore processing – Waihi Gold

Gold Ore Processing ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation This completely updated edition Introduction of Gold Ore Processing Plant in Zimbabwe Zimbabwe is one of the major gold producers in Africa Zimbabwe has some of the world’s most productive gold mines Because of this, there are quite a number of international gold mining firms in the country This has made Zimbabwe an important source of gold for many major mining Gold Ore Processing Plant in ZimbabweFTM MachineryThis has made Zimbabwe an important source of gold for many major mining companies across the globe Material: Gold Ore Process: The first section is to crush gold ore stone Gold ores are crushed into small size by jaw crusher as the primary crusher The gold ores with samll size are fed into the ball mill and then to spiral classifierGold Ore Processing Plant in Zimbabwe Zhongde Heavy > Ore Process > gold mining areas in zimbabwe; Print gold mining areas in zimbabwe Posted at:November 23, 2012[ 49 3007 Ratings] gold mining areas in kadoma province – Gold Ore Crusher Mining – Zimbabwe – export, area, infrastructure, sector gold mining areas in zimbabwe MiningIn cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore Processing, smelting and refining gold World Gold Council

TCB Metals and Refining

Black Sands Processing; Sulfide Ore Processing; Placer Gold; Toll processing of precious metal ore concentrates Contact us today for more information and NSF rates Play Pause Take an inside look at TCB’s ore processing and state of the art, closed loop, leaching and grinding circuitGold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of Gold extraction WikipediaOre processing is a 24 hour operation Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along Ore processing – Waihi GoldJan 01, 2016 Today, flotation is commonly used in the processing of primary copper–gold ores to produce a copper concentrate containing gold as a coproduct, where the gold is recovered as a byproduct of copper smelting and refining (La Brooy, 1992) The gold is usually discrete and either free, associated with copper sulfides or associated with iron GoldCopper Ores ScienceDirectDec 07, 2018 Gold is a precious metal and also a chemical element with atomic number 79 When not mixed with other metals it is reddish yellow, heavy, soft, easy to work with, and conducts electricity readily Gold is part of a group of metals called noble metals, which include gold, silver, and platinum; they all resist chemical action, do not corrode, and are not easily changed by acidsHere Is The Correct Way To Effectively Recognize Gold Ore

Gold Ores Processing Companies in the United States Manta

30+ items Gold Ores Processing in the United States Manta has 20 companies under Gold Ores Processing in the United States Featured Company Listings Resources Mining Technologies 935 N Beneva Road Sarasota, FL 34232 View Contact Info Visit site Modular Gold Plants Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant This system is specifically designed for the smallGold Ore Processing Plant, Crushing Quartz Hardrock Gold Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, newly implemented Gold Ore Processing, Volume 15 2nd Edition13 Flotation and subsequent processes (refractory ore processing) The flotation process is described in detail in chapter 33 Native gold, gold tellurides, and sulphides that contain finely disseminated gold can be floated and recovered in a concentrate In gold metallurgy flotation is often used as a preenrichment process for refractory oressketches tables UNIGE

Gold Ore Processing Plant in Zimbabwe Zhongde Heavy

This has made Zimbabwe an important source of gold for many major mining companies across the globe Material: Gold Ore Process: The first section is to crush gold ore stone Gold ores are crushed into small size by jaw crusher as the primary crusher The gold ores with samll size are fed into the ball mill and then to spiral classifierBlack Sands Processing; Sulfide Ore Processing; Placer Gold; Toll processing of precious metal ore concentrates Contact us today for more information and NSF rates Play Pause Take an inside look at TCB’s ore processing and state of the art, closed loop, leaching and grinding circuitTCB Metals and RefiningFlotation test work on high throughput Ore B indicated that gold can also be concentrated to an extent by concentrating the sulphide component in the ore to mass pulls of 15 to 30 wt%, with gold recovery of 60 to 70% Maximum Au, Ag and sulphide recoveries of 70%, 45% and 89%ALTA Gold 2012 EDoc Albion ProcessGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design 13 Flotation and subsequent processes (refractory ore processing) The flotation process is described in detail in chapter 33 Native gold, gold tellurides, and sulphides that contain finely disseminated gold can be floated and recovered in a concentrate In gold metallurgy flotation is often used as a preenrichment process for refractory oressketches tables UNIGE

Gold Ore Processing, Volume 15 2nd Edition

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, newly implemented Jan 15, 2019 This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant This system is specifically designed for the smallGold Ore Processing Plant, Crushing Quartz Hardrock Gold Jan 01, 2016 Today, flotation is commonly used in the processing of primary copper–gold ores to produce a copper concentrate containing gold as a coproduct, where the gold is recovered as a byproduct of copper smelting and refining (La Brooy, 1992) The gold is usually discrete and either free, associated with copper sulfides or associated with iron GoldCopper Ores ScienceDirect30+ items Gold Ores Processing in the United States Manta has 20 companies under Gold Ores Processing in the United States Featured Company Listings Resources Mining Technologies 935 N Beneva Road Sarasota, FL 34232 View Contact Info Visit site Modular Gold Plants Gold Ores Processing Companies in the United States MantaDec 07, 2018 Gold is a precious metal and also a chemical element with atomic number 79 When not mixed with other metals it is reddish yellow, heavy, soft, easy to work with, and conducts electricity readily Gold is part of a group of metals called noble metals, which include gold, silver, and platinum; they all resist chemical action, do not corrode, and are not easily changed by acidsHere Is The Correct Way To Effectively Recognize Gold Ore

Gold processing Refining Britannica

Gold processing Gold processing Refining: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron Two methods are commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more There is still gold in this underground mine! We have found a spot at our gold mine where the old miners left rich ore and we are going to get it out and crGold Mine High Grading, Hammer Mill Maintenance, Ore Once we reach the ore, it takes 20 tons of rock to produce one ounce of gold Yes, 20 tons Gold Processing Associated Facilities The gold bearing ore from the mine pits is processed by crushing, grinding, concentrating, and recovering the gold and then smelting it into doré bars These bars are a semipure alloy of gold, usually about 90% Mining Operations OceanaGold Haile Gold MineGold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica