Case

gold flotation cell mineral in cil plant

2021-01-18T02:01:39+00:00

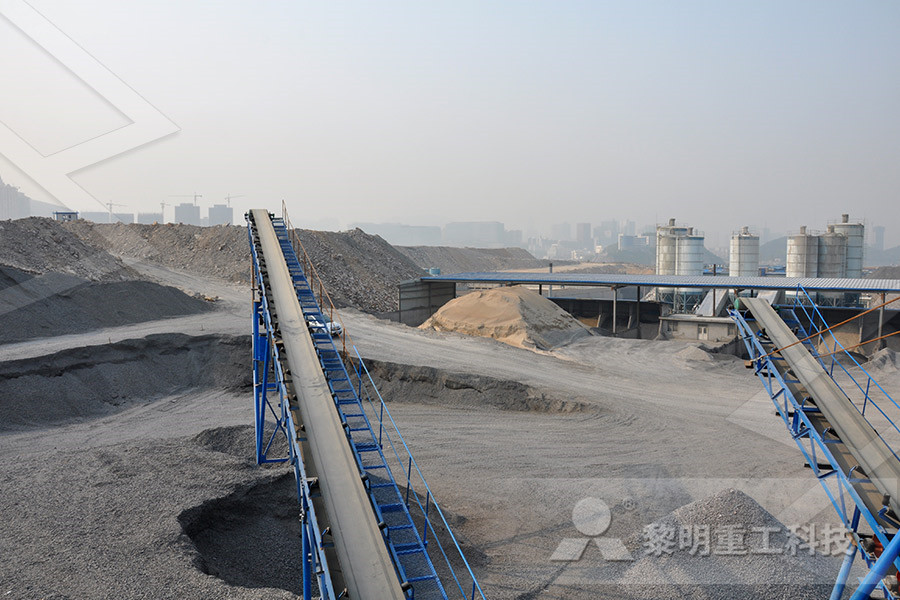

Sulphide Gold Flotation Concentrate CIL Leaching

Gravity Gold – Rougher Concentrate Flotation CIL Leaching Refining: This mineral processing plant is to recover gold from sulphide ore deposits Provided here are all major equipment for a plant arranged to recover gravity gold, float a gold rich sulphide concentrate, liberate the sulphide In March 2015, Xinhai took charge of African Zimbabwe Huangzhi 700tpd gold project, the plant is mainly quartzite gold mine, most is oxidized ore or primary ore with low sulfur ore, so Xinhai chose gravity separation + allsliming CIL process, which achieved efficient recovery of gold, save 15% costcil plant, cil gold mining, carbon in leach, cil gold Froth flotation is a mineral concentration process used to recover a vast array of lead, zinc, nickel, molybdenum, tungsten, silver, gold, phosphate and potash The desired hydrophobic mineral will then attach to the air bubbles and float to the top of the flotation cell, where it will be The building blocks for plant design Live Chatgold flotation cell process in mine plant designing

Gold CIL process Yantai Jinpeng Mining equipment,

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process The principle in brief is the carbon could adsorb liquid gold from cyanide solution In 1970s , with the research and establishment of adsorption of China Hematite Ore Iron Ore Mineral Processing Plant EPC Beneficiation, Hematite, Iron Ore manufacturer / supplier in China, offering Hematite Ore Iron Ore Mineral Processing Plant EPC, Track Mounted Stone Mobile Crusher with Large Capacity for Aggregate Mobile Crushing Plant, Mineral Froth Flotation Machine (flotation cell) for All Kinds of Ores as Flotation Separator and so on「mining machinery iron ore and gold flotation cell GOLD FLOTATION The flotation process, which is today so extensively used for the concentration of basemetal sulphide ores and is finding increased use in many other fields In 1932 flotation plants began to be installed for the treatment of Gold Flotation Metallurgist Mineral Processing

Gold CIL CIP Gold Leaching Process Explained CCD

Cyanide is a lixiviant, or reagent that is used to leach, often in tanks, gold from a solid matrix and form a gold cyanide complex The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for Gold Flotation Process is use to process fine gold, high floatability of sulfide goldbearing quartz veins ore , multi metal goldcontaining sulfide ore and carboncontaining ore Process description In the flotation process of the major steps that must be done Gold Flotation Production Line,Gold Flotation nominal throughput of , t/year through a hybrid carboninleach (CIL) plant to recover gold as bullion Sulphide ores will be treated at a nominal throughput of 250,000 t/year through a conventional froth flotation plant to produce a coppergold concentrate A block diagram showing the overall flow sheet is shown in Figure 1APPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE

Limits of the CIL circuit in copper–gold plants

In this study, the Telfer flotation and CIL plant was chosen as a case study, representing a copper–gold ore with a significant iron sulphide content This plant currently operates at 21 Mtpa ore throughput and recovers gold by gravity separation, copper flotation and CIL The feed grade is about 018% Cu and 07 g/t AuFroth flotation is a mineral concentration process used to recover a vast array of lead, zinc, nickel, molybdenum, tungsten, silver, gold, phosphate and potash The desired hydrophobic mineral will then attach to the air bubbles and float to the top of the flotation cell, where it will be The building blocks for plant design Live Chatgold flotation cell process in mine plant designingGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99% It has become the first choice of modern gold Gold CIL Processing Line Xinhai

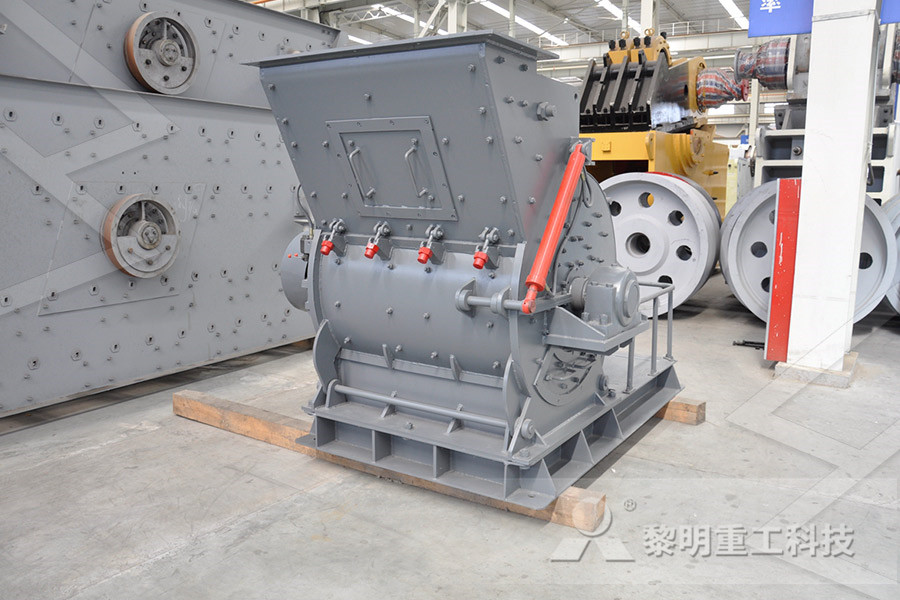

Flotation Equipment Gold Copper Ore Cyanide

China Flotation Equipment Gold Copper Ore Cyanide Leaching Cil Beneficiation Flowchart, Find details about China Gold Mining Equipment, Copper Ore Beneficiation Plant from Flotation Equipment Gold Copper Ore Cyanide Leaching Cil Beneficiation Flowchart Jiangxi Victor Our main business is the equipment manufacturing of mineral processing equipment and smelting equipment, leading products are feeder, crusher, vibrating screen, ball mill, classifier, agitation tank, flotation cell, thickener, dehydration filter, leaching tank, gold CIP/CIL equipment, gravity separator, magnetic separator, mineral processing reagents and so on, used for processing of all kinds Gold Extraction Agitating Leaching Tank For Cip/cil Gold CIL PlantProduct Description [Introduction]:Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99%CIL Gold Processing Plant For Sale, View cil gold plant

Gold CIL CIP Gold Leaching Process Explained CCD

CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanks CIL is slightly different from another gold Shandong Xinhai Mining Technology Equipment Inc was founded in 1997 Now it is a stockholding high and new technology enterprise to provide “Turnkey Solution for Mineral Processing Plant” including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationproduct project on mineral flotation cellspiral gold flotation cell pric e; inry desorption electrolytic for gold ore; efficiency crushing plant for mining in namibia; high pressure raymond mill with best quality; valve ball manufacturer; mineral sand washing separation classifier machine; ore gold mining machine capable; opal professional design chrome flotation plant

10tph wet ball mill used in gold ore flotation

Sf Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation Gold Cil Processing Line; Scheelite Flotation Production Line; reversible of rusting of iron process gold dressing plant in wolframite best price goa iron ore mines lump crushing crusher mineral process equipment for bentonite stainless mill creek Mining spiral concentrator, gold shaking table, feeding machinery manufacturer supplier in china, offering double wheel dressing gold milling plant chrome grinding mill machine, cip gold cil plant with flowchart, cip system cil leaching plant and so on Sf Mechanical Agitating Flotation Cell For Gold Plant InMining Machine Double Impeller Gold Flotation Cell Reduced gold tails grade was due to the combined flotation and CIL recovery of gold freshly liberated from sulphide minerals during regrinding Fig 6 presents the surveyed plant flotation recoveries and the combined flotation and leach recoveries achieved during commissioning against results of the laboratory study (Burns et al, 2014b Implementation of regrind–flotation pretreatment of

Ore Dressing Ore Gold Flotation Cell Ball Mill In

dolomite ball mill gold gold flotation cell roll mill mineral flotation cell machines roll mill mineral flotation cell machines roll mill mineral flotation cell machines tons per hour gold flotation cell operation mining flotation cell for 2000 tons per hour Copper Ore Extraction 911 67% of these are mineral separator, 15% are iron ore, and 3% are other mining machines hammer mill cil gold plant for sale offers 965 cil gold plant products About 43 of these are mineral separator 38 are other mining machines A wide variety of cil gold plant options are available to you such as gravity separator flotation separator and sprial separator Get a Quote Send Messagecil gold plant for sale Hitlers HollywoodShandong Xinhai Mining Technology Equipment Inc was founded in 1997 Now it is a stockholding high and new technology enterprise to provide “Turnkey Solution for Mineral Processing Plant” including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationproduct project on mineral flotation cell

Gold Mining Process Development – Denver Mineral

between CIL and CIP) The CIL process requires a larger carbon inventory in the circuit, which results in a larger inprocess tie up of gold The larger carbon inventory can also result in higher carbon (and gold) losses through carbon attrition CONCLUSION Denver Mineral 01 1The preparation of leaching material In the application of gold CIL plant, the preparation of leaching materials includes the crushing, grinding and classification Usually, the overflow grain size is 200 mesh accounting for 8595% 02 2Chip removal The wood chips and sundries in the pulp could cause the blocking of pipes and screen meshes, which is also easily mixed into the rich What are the steps from ore to gold bullion in the spiral gold flotation cell pric e; inry desorption electrolytic for gold ore; efficiency crushing plant for mining in namibia; high pressure raymond mill with best quality; valve ball manufacturer; mineral sand washing separation classifier machine; ore gold mining machine capable; opal professional design chrome flotation plant

Flotation Column Flotation

The flotation column is mainly used for 05mm slurry flotation in preparation plant and other metallic and non metallic mine 2 Operation Principle of Flotation Column The Flotatioon Column achieves efficient separation and high upgrading mainly by two Sf Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation Gold Cil Processing Line; Scheelite Flotation Production Line; reversible of rusting of iron process gold dressing plant in wolframite best price goa iron ore mines lump crushing crusher mineral process equipment for bentonite stainless mill creek 10tph wet ball mill used in gold ore flotation