Case

two stage crushing for manganese ores

2020-12-03T01:12:28+00:00

manganese ore processing production process Stone

Crushing process, closedcircuit crushing three sections are the most suitable for modern high hardness manganese ore crusher, ore crushing and partial to complete dissociation of the work to improve the followup to the grinding efficiency; grinding process, a twostage grinding is efficient closure the grinding process can grind ore more Mar 04, 2017 Crushing and grinding are the two primary comminution processes Crushing is normally carried out on the "runofm ine" ore The grinding (PDF) SIZE REDUCTION BY CRUSHING METHODSBe used for primary crushing of manganese ore, which will be broken into particle size less than 35 mm Cone crusher Be used for secondary crushing of manganese ore to produce fine grade manganese to under 15 mm 1 The twostage grinding process is adopted, which can not only reduce the mud ore caused by overgrinding of minerals, Manganese Ore Beneficiation Plant With Free Installation Iron Ore Processing; Mineral Processing – Manganese; NatalBorrow Pit Processing; Residential Infrastructure Mobile Crushing; Ventersburg Road Upgrade; Mobile Crushing – Tombo Eastern Cape; Screening; SteelportFerrochrome Crushing; Warehouse Construction; Screening / Scalping; SingleStage Crushing; SingleStage Crushing Screening; Two Two Stage Crushing Screening SenecaMetallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Manganese Ore Processing Mineral Processing Metallurgy

Stone Crushing Machine Karnataka twostage crusher

The jaw crusher is the primary crusher in a comminution circuit for ore sorting and mineral processing Using a twostage crushing circuit with a reduction ratio between 31 and 41 at each stage reduces fines and also decreases the number of particles filtered back to the crusher Benefits of OreIn order to select useful minerals from ores, it is necessary to crush the ores first so that the useful minerals in the ores can reach the state of monomer dissociation The preparatory work before separation usually consists of two stages: crushingscreening and grindingclassificationSome Problems in the Crushing and Grinding Stage of what is two stage fresh ore crushing circuit Concrete Batching Plants are used for manufacturing of highquality concrete in a variety of construction applications, like buildings, roads, bridges, airports and many others MEKA offers a wide range of Ready Mix Concrete Batching Plants along with MEKA Concrete Mixers Mobile, Compact and Concrete Batching Plant prices what is two stage fresh The manganese crushing adopts 2stage crushing process of jaw crusher fine jaw crusher Manganese ore is firstly fed into the vibrating feeder by dumper, then it is put into the jaw crusher for primary crush The crushed coarse manganese is then transported to the fine jaw crusher by belt conveyor for secondary crushManganese ore processing lineCrushing process, closedcircuit crushing three sections are the most suitable for modern high hardness manganese ore crusher, ore crushing and partial to complete dissociation of the work to improve the followup to the grinding efficiency; grinding process, a twostage grinding is efficient closure the grinding process can grind ore more manganese ore processing production process Stone

Manganese Ore, Manganese Ore Processing Production Process

During the stone crushing process, Three sections closedcircuit crushing technology is the latest technology, which is suitable for crushing highhardness manganese ore It can qualify for crushing ore and some dissociation tasks to improve the efficiency of subsequent ore grinding process In the ore grinding process, two sections closed Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Manganese Ore Processing Mineral Processing MetallurgyIron Ore Processing; Mineral Processing – Manganese; NatalBorrow Pit Processing; Residential Infrastructure Mobile Crushing; Ventersburg Road Upgrade; Mobile Crushing – Tombo Eastern Cape; Screening; SteelportFerrochrome Crushing; Warehouse Construction; Screening / Scalping; SingleStage Crushing; SingleStage Crushing Screening; Two Two Stage Crushing Screening SenecaBe used for primary crushing of manganese ore, which will be broken into particle size less than 35 mm Cone crusher Be used for secondary crushing of manganese ore to produce fine grade manganese to under 15 mm 1 The twostage grinding process is adopted, which can not only reduce the mud ore caused by overgrinding of minerals, Manganese Ore Beneficiation Plant With Free Installation For example, a gold mine in Shandong Province transformed the twostage and oneclosedcircuit crushing process into twostage and halfcrushing process, solved the problem of reasonable matching between the production capacity and crushing ratio of the secondstage crushing equipment,and achieved obvious economic benefits in production 2Some Problems in the Crushing and Grinding Stage of

The 7 Most Useful Manganese Ore Beneficiation Methods

Jan 14, 2021 At present, the process of manganese oxide ore dressing in China is generally to crush the ore to 6~0 mm or 10~0 mm, and then the coarsegrade for jigging, and finelevel for tabling dressing It is essential to recover as much manganese as possible in the gravity concentration zone because its grinding cost is much lower than the manganese in Manganese Ore Washing Plant And Crusher In Zambia Manganese ore washing and screening plantanganese ore crushing wash cz eu manganese crusher and wash plant in zambia copper ore dressing equipment south africa has a 2015 large capacity iron ore crusher machine 12 sep 2012 iron ore jaw crusher is the iron ore crushing plant which has special capacity in iron oreearn moreget priceMine Plant Design And Screening Of Manganese OreJIgging machine For fine manganese ore with large capacity For different requirement about treatment capacities, Forui jigger of LTA1010/2, LTA1515/2, 2LTC6109/8T jigger can be chosen for this low grade manganese upgrading These jigging separation machines uses water only to beneficiate this low grade manganese ore and it is environmentfriendlyBeneficiation and Upgrading Of LowGrade Manganese OreOre Crushing Stages Crushing Equipment List Caesar Heavy Because gold mining plant is a complex process, the crushing stage is the basic stage in the plant, so the crushing equipment is very significant can provide you professional gold ore crushing plant, many mining applications have proved that s PEW series jaw crusher can performs an efficient gold ore crushing machineVarious Ore Crushing Equipment For Several Stages Of CrushingManganese ore jaw crusher and mobile jaw crusher have the input size of 1201500mm, so they are best primary crusher for large manganese ore Manganese ore cone crusher has the input size of 60285mm, so you can use it as secondary crusher for further crushing of manganese oreManganese Ore Crusher, Manganese Ore Crushing Machine

Iron Ore Seneca Crushing

Iron Ore Processing; Mineral Processing – Manganese; NatalBorrow Pit Processing; Residential Infrastructure Mobile Crushing; Ventersburg Road Upgrade; Mobile Crushing – Tombo Eastern Cape; Screening; SteelportFerrochrome Crushing; Warehouse Construction; Screening / Scalping; SingleStage Crushing; SingleStage Crushing Screening; Two Crush and grind bulk ferrosilicon or magnetite used as media solid to the required size in advance The crushing and grinding process usually consists of jaw crusher ball mill spiral classifier screen etc 【Ore beneficiation】 Ore beneficiation is the separation of light and heavy minerals in the heavy medium separation machineStone Crushing Machine Aurangabad twostage crusher Crushing process, closedcircuit crushing three sections are the most suitable for modern high hardness manganese ore crusher, ore crushing and partial to complete dissociation of the work to improve the followup to the grinding efficiency; grinding process, a twostage grinding is efficient closure the grinding process can grind ore more manganese ore processing production process Stone The manganese crushing adopts 2stage crushing process of jaw crusher fine jaw crusher Manganese ore is firstly fed into the vibrating feeder by dumper, then it is put into the jaw crusher for primary crush The crushed coarse manganese is then transported to the fine jaw crusher by belt conveyor for secondary crushManganese ore processing lineIn order to achieve good enrichment of manganese ore, the material after two crushing needs to be further crushed by the HP300 hydraulic cone crusher; the crushed material is reasonably screened by the circular vibrating screen, and only qualified materials that meet the requirements can go to the next stage, otherwise it will be sent back to Manganese Ore Processing Solution Eastman Rock Crusher

Manganese Ore Beneficiation Plant With Free Installation

Be used for primary crushing of manganese ore, which will be broken into particle size less than 35 mm Cone crusher Be used for secondary crushing of manganese ore to produce fine grade manganese to under 15 mm 1 The twostage grinding process is adopted, which can not only reduce the mud ore caused by overgrinding of minerals, Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Manganese Ore Processing Mineral Processing MetallurgyManganese ore jaw crusher and mobile jaw crusher have the input size of 1201500mm, so they are best primary crusher for large manganese ore Manganese ore cone crusher has the input size of 60285mm, so you can use it as secondary crusher for further crushing of manganese oreManganese Ore Crusher, Manganese Ore Crushing Machine JIgging machine For fine manganese ore with large capacity For different requirement about treatment capacities, Forui jigger of LTA1010/2, LTA1515/2, 2LTC6109/8T jigger can be chosen for this low grade manganese upgrading These jigging separation machines uses water only to beneficiate this low grade manganese ore and it is environmentfriendlyBeneficiation and Upgrading Of LowGrade Manganese Orestage, the synthetic ore of first stage was smelted with coke and limestone to produce high carbon ferro manganese containing upto 7070 Mn at a temperature of 1600 1650°C with a slag base to acid ratio exceeding 15% In the strategic UDY process, ferruginous manganese ores and low grade ore A Strategy for utilisation of low grade high phosphorus

Various Ore Crushing Equipment For Several Stages Of Crushing

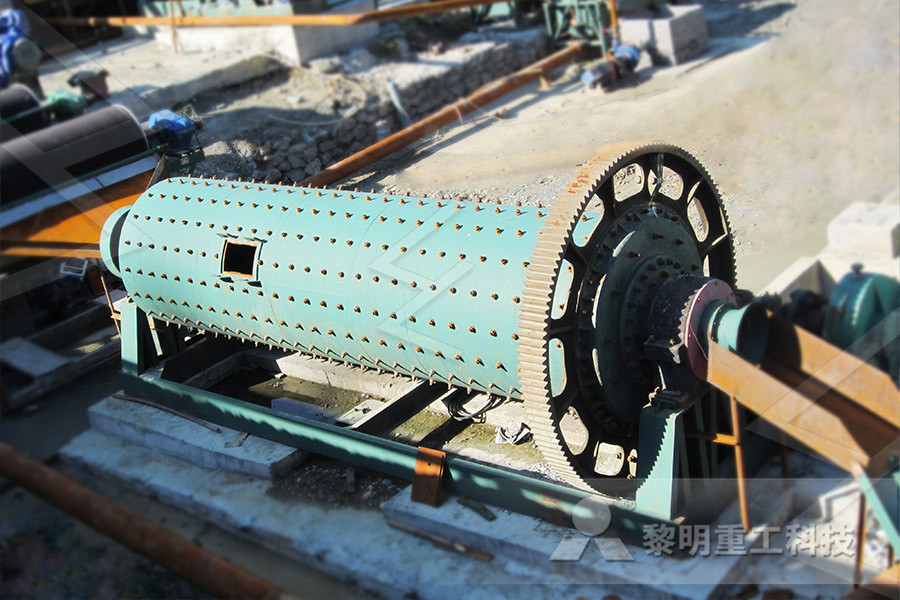

Ore Crushing Stages Crushing Equipment List Caesar Heavy Because gold mining plant is a complex process, the crushing stage is the basic stage in the plant, so the crushing equipment is very significant can provide you professional gold ore crushing plant, many mining applications have proved that s PEW series jaw crusher can performs an efficient gold ore crushing machineIron Ore Processing; Mineral Processing – Manganese; NatalBorrow Pit Processing; Residential Infrastructure Mobile Crushing; Ventersburg Road Upgrade; Mobile Crushing – Tombo Eastern Cape; Screening; SteelportFerrochrome Crushing; Warehouse Construction; Screening / Scalping; SingleStage Crushing; SingleStage Crushing Screening; Two Iron Ore Seneca CrushingCrush and grind bulk ferrosilicon or magnetite used as media solid to the required size in advance The crushing and grinding process usually consists of jaw crusher ball mill spiral classifier screen etc 【Ore beneficiation】 Ore beneficiation is the separation of light and heavy minerals in the heavy medium separation machineStone Crushing Machine Aurangabad twostage crusher mining machine of manganese ore crusher machine Mobile Crusher Machine for Manganese Mining With the development of quarrying and mining industries many new types of mining equipment are designed for various applications Crushing is the first stage in manganesemining operation so crushing equipment plays important role in manganese mining plantmining machine of manganese ore crusher machineCrushing, Screening and Mineral Processing Equipment Crushing, Screening, and Mineral Processing Equipment Market Outlook 2025 The global crushing, screening, and mineral processing equipment market growth was valued at $191212 million in 2017, and is projected to reach $33,1164 million by 2025, growing at get pricemanganese ore beneficiation flow sheet

beneficiation manganese fines pelletizing

Iron Ore Processing Crushing Screening Grinding Beneficiation China's iron ore grinding process the majority of twostage grinding process a Sintering and Pelletizing on Ore Fines/blue dust cannot be charged in the blast Chat Now Iron ore pelletizing This process primarily used for iron ores can also be used for sintering manganese and