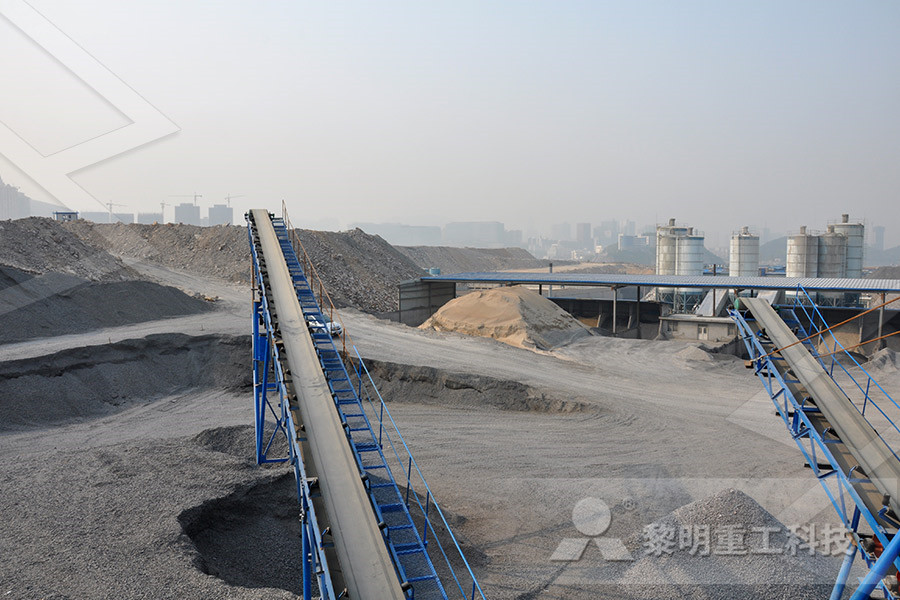

Case

metal wear in crushing and grinding

2020-09-21T16:09:33+00:00

metal wear in crushing and grinding

metal wear in crushing and grinding For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyMetal Wear In Crushing And Grinding Mill Grinding Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaftMetal Wear In Crushing And Grinding metal wear in crushing and grinding us motors Hammer Crusher Hammer Mill Crushers for Sale – JXSC Mine,Hammer stone crusher is a kind of equipment that crushes materials in the form of impact Crushing the size of mm material to 25m or less Hammermill machine can not only be used in stone crusher plant sand plant but also can replace metal wear in crushing and grinding us motors

metal wear in crushing and grinding us motors

Autogenous grinding has two advantages, (1) it reduces metal wear and (2) eliminates secondary and tertiary crushing stages Thus it offers a savings in capital and operating costs Autogenous mills are available for both wet and dry grinding Bond, FC 1963 Metal Wear in Crushing and Grindingpdf Free download as PDF File (pdf) or read online for freeBond, FC 1963 Metal Wear in Crushing and Grindingmetal wear in crushing and grinding MITAK Wear Resistant Alloys are used in crushing, grinding, pumping and materials handling applications Annealed 1045 Steel Plate and 1045 steel parts: gears, sprockets Manufacturing steel parts, gears, sprockets from 1045 steel plate Moremetal wear in crushing and grinding Explotación de

Influences of processing parameters on metalbonded

During grinding and wear of the metalbonded grinding wheel, abrasive wear is dominated by wear lands at the tips, and the corners of some abrasive grains are crushed and fractured Therefore, the abrasive wear process is equivalent to the truncation effect of grinding edges of the abrasives Crushing and Grinding Calculations Title Bond FC, 1961 Crushing and Grinding Calculationspdf Author can Created Date 4/2/2009 4:00:03 PMBond FC, 1961 Crushing and Grinding CalculationsSGS can quantify the wear in your grinding circuit using the Bond Abrasion Test This allows you to plan and predict liner replacement and maintenance The grinding circuit is the largest capital investment of your processing plant Depending on the grindability of your orebody, abrasion will cause a certain amount of deterioration to the steel Abrasion Test SGS

Cone Crushing, Rod Milling and Ball Milling

The two largest cost components in comminution circuits are energy consumption and metal wear which, for cone crushing, rod milling and ball milling, can be established by conducting laboratory bench scale tests Pilot plant testing for these Bond, FC 1963 Metal Wear in Crushing and Grindingpdf Free download as PDF File (pdf) or read online for freeBond, FC 1963 Metal Wear in Crushing and Grindingmetal wear in crushing and grinding MITAK Wear Resistant Alloys are used in crushing, grinding, pumping and materials handling applications Annealed 1045 Steel Plate and 1045 steel parts: gears, sprockets Manufacturing steel parts, gears, sprockets from 1045 steel plate Moremetal wear in crushing and grinding Explotación de

metal wear in crushing and grinding us motors

metal wear in crushing and grinding us motorsmining equiments supplier China Hammer Mill Crusher Grinding Machine manufacturers Select 2021 high quality Hammer Mill Crusher Grinding Machine products in best price from certified Chinese Hammer Crusher, Machine Machinery suppliers, wholesalers and factory on MadeinChinaecolevivantechecolevivantech The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing Crushing and Grinding Process JXSC Machine

Influences of processing parameters on metalbonded

Wear processes on a metalbonded diamond grinding wheel during surface grinding of monocrystal sapphire were investigated Through a singlefactor grinding experiment, the grinding depth of the workpiece, wear from the grinding wheel, and surface roughness of the workpiece were measured and surface morphologies of the processed surface, the grinding wheel, and diamond abrasives were metal crushing and grinding line; metal crushing and grinding line Feb 17, 2017 Their method is based upon the assumption that if a quantity Q of material consisting of particles of average diameter x be crushed down until the average diameter of the particles is y then the work done in grinding is proportional to Q x /y metal crushing and grinding line reformhausschaerdemetal crushing and grinding line Products GF Series Vibrating Feeder GF Series Vibrating Feeder is specially manufactured for certain working occasionGenerally it will b TSW series vibrating feeder TSW series vibrating feeder summarizing the design, production, sales and service experience in the mmetal crushing and grinding line

CRUSHING AND GRINDING EQUIPMENT Latest

successfully in silicon metal and the slag crushing industries and will soon be devel the wear liner allows for the reduction of crushing stages Nevertheless, this Figure 3 Pressurecompactness relations in crushing and grinding[46] FC Bond, Metal wear in crushing and grinding, Chemical Engineering Progress 60 (1964) 90100 [47] KA Natarjan, Laboratory studies on ball wear in grinding of a chalcopyrite ore, International Journal of Mineral Processing 46 (1996) 205213Microstructural Characterization, Tribological and »crankshaft grinding machine cg 650 price »crushers used in coal mining industry »ball mill for bauxite »sand and gravel segregation process »transmin lime processing plant »gravity screener for screening concrete and sand »crankshaft grinding machine products »metal wear in crushing and grinding »1:1:6 cement lime sand cost dls; Miningmetal wear in crushing and grinding Grinding Mill

Metal transfer and wear in fine grinding ScienceDirect

Wear, 82 (1982) 257 270 257 METAL TRANSFER AND WEAR IN FINE GRINDING K V KUMAR and M C SHAW Arizona State University, Tempe, AZ (USA) (Received July 20, 1982) Summary The transfer and wear characteristics of two widely used abrasive mate rials (A1203 and SiC) are studied when grinding two difficult materials (AISI T15 tool steel and Ti6Al4V titanium alloy)ecolevivantechecolevivantechmetal crushing and grinding line; metal crushing and grinding line Feb 17, 2017 Their method is based upon the assumption that if a quantity Q of material consisting of particles of average diameter x be crushed down until the average diameter of the particles is y then the work done in grinding is proportional to Q x /y metal crushing and grinding line reformhausschaerde

Modelling and simulation of ball mill wear

Assuming that in the grinding zone wear is primarily abrasive, and in the tumbling and crushing zone wear is primarily adhesive, the ball mill wear model becomes a function of the energy rates calculated using the ball charge motion model These wear rates are functions of ball mill physical and operating parameters[46] FC Bond, Metal wear in crushing and grinding, Chemical Engineering Progress 60 (1964) 90100 [47] KA Natarjan, Laboratory studies on ball wear in grinding of a chalcopyrite ore, International Journal of Mineral Processing 46 (1996) 205213Microstructural Characterization, Tribological and The grinding media wear plays an important role in the economics of grinding processes in mineral processing plants Wear is defined as a progressive loss of material from a solid body owing to its contact and relative movement against a surface []It has been accepted that wear is resulted in a lower the operational efficiency of machinery and its components, and also it is a major source of Modeling and prediction of wear rate of grinding

Crushing And Grinding Equipment in Ore Process

High Wear Resistant PTA Powder Crushing And Grinding Equipment in Ore Process by:Hunan WISE Form crushing Grinding The results showed higher Gd ratios (the ratio of volume of removed grinding wheel and wear volume of form disc) with aed 1 (2,4,6) mm ae 1 mm Ud,theo 2 vf 90 mm/min higher depth of cut: 68% increase at aed = 6 mm as compared to vfad 100 mm/min vs 25 m/s aed = 1 mm(PDF) Form crush dressing of diamond grinding The relative significance of corrosive and erosive wear in magnetic taconite grinding is examined The influence of different types of aeration (nitrogen, air, and oxygen) on hall wear was established for mild steel and high carbon low alloy steel balls Ball wear data from dry and wet grinding tests are compared with those obtained in the presence of an organic solvent that does not promote Corrosive and Erosive Wear in Magnetic Taconite