Case

impact grain crushers

2020-01-09T11:01:29+00:00

Impact Crusher an overview ScienceDirect Topics

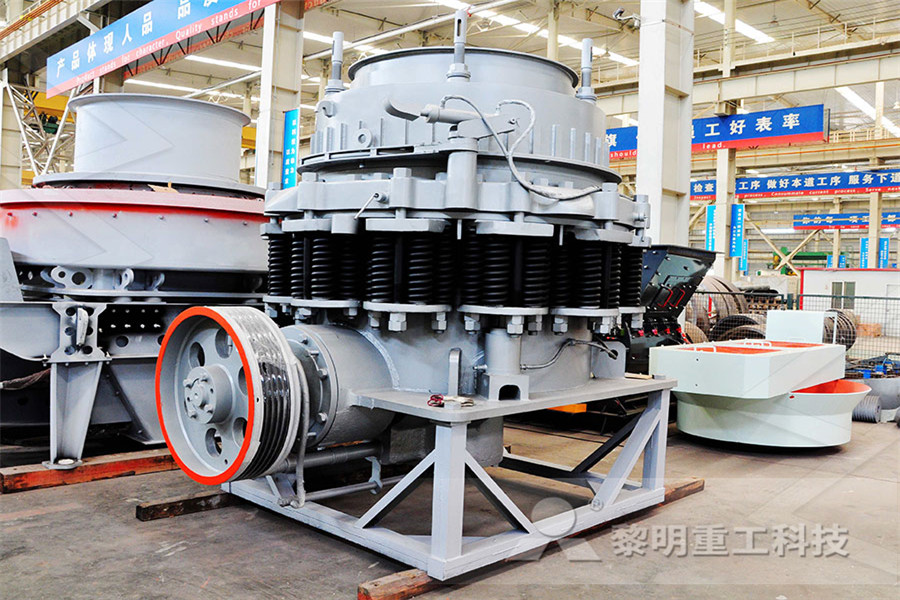

Impact crushers provide better grainsize distribution of RA for road construction purposes and are less sensitive to material that cannot be crushed (ie steel reinforcement) Gyratory crushers, which work on the same principle as cone crushers ( Fig 8 c), exhibit a gyratory motion driven by an eccentric wheel and will not accept materials with large particle sizes as they are likely to become jammedImpact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each otherImpact crushers highquality impactors Minyu Impact Crushers are designed with an extra large feed opening, hydraulic hood opening, and automatic adjustment control Due to simple structure, low power consumption, high crushing ratio, and even grain distribution, our Impact Crushers have a wide application in multiple fields An Impact Crusher Impact Crushers Crushing Equipment Minyu

Tertiary Impact Crushers MEKA Crushing

Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications Adjustable and interchangeable impact grain crushers gujaratgenomicsin Home >impact grain crushers impact crusher pfv 1214 pricefob exw usd impact crusher for sale Impact Crushers For Sale Impact Leer más Producing highquality rock grains with impact impact grain crushers campusfrancorchampsbe Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser fragmenting it much more significantly and grinders reducing it to a fine power Impact crushers: they involve the use of impact rather than pressure to crush materialsDESIGN AND ANALYSIS OF IMPACT CRUSHERS

INFLUENCE OF ROTARY GRAIN CRUSHER PARAMETERS

impact destruction Therefore, when grinding grain in the crushers discussed, less efficient types of impact crushing of grain are used: the impact upon the sieve and the particle collision The presence of an annular sieve in the grinding chamber leads to Whether in a quarry or on a construction site, impact crushers crush stone so efficiently that the grain shape, grain size distribution and cleanness comply with the strict standards for concrete and asphalt aggregates The impact crushing plants not only achieve a firstclass product quality but also a remarkable throughputCrushing technology Technologies The principle of operation lies in the fact that grain enters the hammer drum, which rotates inside and is subjected to the impact of special hammers In the course of blows grain is crushed and turns into compound feed The size of the grains after grinding is Grain Crusher General information 2021

grain crusher equipment falconsrestcoza

Grain crusher is a kind of mechanical equipment used to break all kinds of grain The purpose of grain crushing is to increase the grain size and surface area and increase the palatability of the feed which is suitable for digestion At the same time the grain crusher Chat OnlineIn the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical roller mills EQUIPMENT The HPI Crusher has two impact aprons and can also be equipped with a PRIMARY IMPACTORS HPI Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers Impact Crusher Rock Crusher Machine Manufacturer

Impact Crusher, Mini Pulverizers, Grinding Mill,

The Impact Crushers are used for crushing or shredding of diverse materials such as: Limestone, Glass, Coal and Lignite, Clay, Sand, Phosphate, Rock, Fertilizer, Aluminium Oxide, Slags, Coke, Silica, Bauxite, Dolomite, Grain, Barytes, etc Outstanding Features of Impact Crusher Impact The PTKS Impact Crushers are used as reversible secondary crushers and for crushing the often unwanted oversized grain with only one process directly to a fixed defined end product size This is ensured by the front impact of the incoming material and firmly fitted grinding path, so that the crushing can occur at the entire front surface and Reversible impact crusher PrallTec Mobile secondary impact crushers In contrast to KLEEMANN impact crushers for primary crushing stages the secondary impact crushers are equipped with a third impact toggle a socalled "grinding path" This impact toggle is not responsible for crushing the material but ensures the ever so important cubicity of the grain Chat Online; Mobile grain crusher equipment falconsrestcoza

Crushing technology Technologies

Whether in a quarry or on a construction site, impact crushers crush stone so efficiently that the grain shape, grain size distribution and cleanness comply with the strict standards for concrete and asphalt aggregates The impact crushing plants not only achieve a firstclass product quality but also a remarkable throughput MOBILE IMPACT CRUSHERS For high crushing rates and highquality end product with cubic grain shape in the 1st and 2nd crushing stage USED IN: > Soft to mediumhard natural stone > Recycling MOBISCREEN MOBILE SCREENING PLANTS Classifying or coarse grain screens USED IN: > All natural stones > Recycling > Ores Tracked and wheeled stackers USED IN:MOBILE CRUSHING AND SCREENING PLANTS PRODUCT Rockster Impact Crushers are characterized by some special features: High and constant performance thanks to the hydrostatic drive, as well as optimum adaptation of the system components Overload protection of the crusher unit Fully hydraulic adjustment of the swing beams without mechanical fixing, with integrated measuring systemCrushers Rockster

Hammer Mill Crusher Grinder 911 Metallurgist

A certain amount of impact breaking does take place between hammers and grates, but this is secondary to the work done against the involute plates On friable material this machine will deliver a medium fine (025″ to 3/8″) product with some, or even all, of the grates removed Capacity of Hammer Mill Crushers crusher tools EG Jaw liners are subject to numerous pressure and impact stresses Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher type for the abrasive content of the material to be crushedR Crusher Wear Parts Reference Guide CorporationMEKA primary impact crushers are equipped with modern solutions to make the maintenance process more efficient and to reduce maintenance duration This helps the crusher to operate safely and boosts productivity MEKA primary impact crushers are Primary Impact Crushers MEKA Crushing

Impact Crusher, Mini Pulverizers, Grinding Mill,

The Impact Crushers are used for crushing or shredding of diverse materials such as: Limestone, Glass, Coal and Lignite, Clay, Sand, Phosphate, Rock, Fertilizer, Aluminium Oxide, Slags, Coke, Silica, Bauxite, Dolomite, Grain, Barytes, etc Outstanding Features of Impact Crusher Impact The PTKS Impact Crushers are used as reversible secondary crushers and for crushing the often unwanted oversized grain with only one process directly to a fixed defined end product size This is ensured by the front impact of the incoming material and firmly fitted grinding path, so that the crushing can occur at the entire front surface and Reversible impact crusher PrallTec Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers Impact Crusher Rock Crusher Machine Manufacturer

Primary Impactor HPIH

In the cement industry, the HPIH series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical roller mills EQUIPMENT The HPIH Crusher has two impact aprons and Title The Impact of the Grain Transportation Reform on Canadian Canola Crushers Author(s) Paddock, Brian Bowen, Judy Subject(s) Crop Production/Industries International Relations/Trade Issue Date 199412 Publication Type Working or Discussion Paper DOI and The Impact of the Grain Transportation Reform on Hopper Grain Trailer,Impact Crushers For Sale: 134 Hopper Grain Trailer,Impact Crushers Find Hopper Grain Trailer,Impact Crushers on Equipment TraderHopper Grain Trailer,Impact Crushers For Sale

types of grain crushers Purple Academy

Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage type disintegrator Get Price >> Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushersImpact Crusher VS Hammer Crusher JXSC MineThe impact of COVID19 on the grains and oilseeds sector Derek Gerald Brewin grain to market and causing potential delays within the supply chain Regulators and industry are both concerned with potential bottlenecks between millers and crushers and retail buyers of staple goods and between farm supplies and to export buyers (Kurbis The impact of COVID‐19 on the grains and oilseeds sector