Case

al mill system ball mill used in power plant pdf

2023-08-20T23:08:09+00:00

RESEARCH ON COAL PULVERIZING SYSTEM OF THE

RESEARCH ON COAL PULVERIZING SYSTEM OF THE POWER PLANT 269 Figure 1 ball mill middle warehousing coal pulverizing system of recirculating gate However, neither three single circuits can achieve to desired control, because the system is di–cult to be controlled As follows: 1) coal quantity in the coal mill is di–culty to be measured instantly Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion The operating characteristics of bowl mills make it the best mill available for the direct firing system of the coal The best features of all the pulverisersCoal Mills in Thermal Power Plant Mill (Grinding The mill model is running in parallel with the power plant coal mill operation; the measured and predicted outputs are displayed on the computer screens in the power plant control room When the measured and predicted mill outputs are over the preset threshold values, the system will raise alarm reports to give warning signalsA new modelbased approach for power plant Tube

Fire and Explosion Prevention in Coal Babcock Power

BALL TUBE MILL COAL FEED COARSE WET COAL FEEDER PRIMARY AIR CRUSHER DRYER BYPASS DAMPER Figure 4 Ball Tube Mill Pulverizing System 8 Operate at system primary air temperatures below those historically used as normal The trend is toward classifier outlet temperatures of 125 OF away from 150 160 OFOperating data from a coal mill is used to compare the fault detection observerbased method and PCA/PLS models based approach There are 13 process measurements available representing different temperature, mass flows, pressures, speed etc in the coal mill The measurement is not updated, if the variation is less than 1%Coal Mill an overview ScienceDirect Topics 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer millCoal mill pulverizer in thermal power plants

A neural intellectual decoupling control strategy for a

In this paper a multivariable decoupling control algorithm for the coalpulverizing system of a ball miller is provided It is based on a threeneuron control mechanism and solves the problem of long delay and strong coupling in ball mill coal pulverizing systems The main sources of fuel used in power stations across in the UK (UK Energy Statistics, 2005) to generate electricity are: Gas 40%, Coal 33%, Nuclear 19%, Electricity Imports 25%, Oil 1%, Hydro 1% and Other Fuels ( eg Wind, Biomass) 35% Coalfired power stations in the UK generate around 35% of electricity Coal fired power stationsDevelopment of a tube ball mill mathematical model for Ball mill, providing grinded coal for the boiler, is an important role in a thermal power plant and consumes 15 ~ 25 % of the whole energy consumption of the thermal power plant Therefore, ensuring the efficiency of ball mill operation is of consequence for the sake of energyDensity clustering analysis of fuzzy neural network

Chapter 7 COAL Pennsylvania State University

Coal is an organic rock (as opposed to most other rocks in the earth's crust, such as clays first commercial nuclear power plant began operating in 1954 in Shippingport, One such system, most commonly used in the United States, is summarized in Figure 73 and Table 72 ball mill, such as coalfull, coalofi, temperature excursion, coalloss etc On the other hand, the control system can’t run in the max capacity in long time So, keeping the safe running of the ball mill and reducing the power consumption of the speciflc coal mill, increasing the input rate of the automatic control system areRESEARCH ON COAL PULVERIZING SYSTEM OF THE validation technology, developed based on a ball tube mill system, can be readily applied on other types of mill systems, since the steam inerting principle is the same and inerting system requirements are similar, regardless of different mill types INTRODUCTION In a coalfired power plant, the coal pulverizer is critical for fuel processingMill Steam Inerting System Review and Babcock Power

Coal Mill Pulverizer Pdf mayukhportfolioco

Coal pulverizer for rolling mill consist coal handling system power plant pdf coal mill grinder for sale in jordan Read more ball and tube mill pulverizer pdf files[crusher and mill] Read more pulverizing coal hammer mill pdf Pulverizer Wikipedia, the free encyclopedia For example, a pulverizer mill is used to pulverize coal 2 The coal mill The work presented in this chapter is based on a MKM33 ball mill used at Rybnik Unit 4 (rated capacity 220 MW) The mill is one of six mills supplying the 650k (steam production of 650 t/h) boiler However, the proposed method in this chapter is so generic that it can be applied to other types of coal millsDetection of Malfunctions and Abnormal Working The coal fired thermal power plant susceptible to a wide range of hazards in coal bunker and send it to the ball mill or roll mill for pulverization process Where coal crushed to the fine powder cooling system failure 1 4 5 C Regular inspection, maintenanceHazards Identification and Risk Assessment in Thermal

Coal Pulverization System: Explosion Prevention and

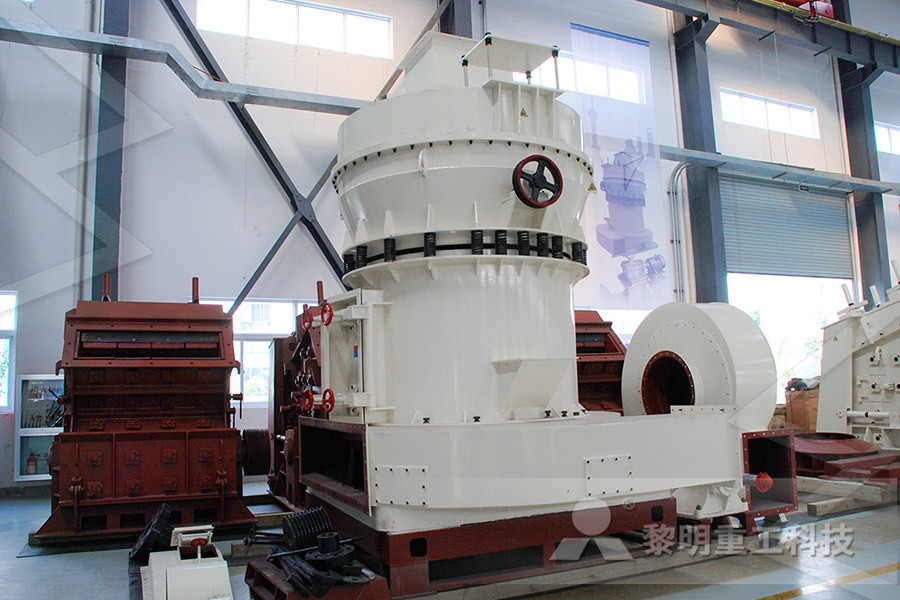

Pulverized coal producing processes are widely used in thermal power stations, cement and ironsmelting industry Many accidents and protection techniques have been reported by former investigations [13] Normally, the traditional coal process systems use ball mills to pulverize coal Flue gases are used as drying and • The Wet Ball Mill system ensures lime stone crushing upto particle size of 44 micron (325 mesh 90%) • Hydro cyclone is used to separate the limestone slurry at the wet Ball Mill outlet • Each set of mill is equipped with a group of limestone slurry hydro cyclones, and can meet the requirement of limestone slurry finenessFlue Gas Desulphurization (FGD) plant 2 x 600 MW Coal Coal Mills in thermal power plant Mill Grinding Principles of grinding raw coal is fed into the mill for grinding grinding takes place by impact and attrition mill details design coal capacity tonshr ball charged tons speed to rpm screw assebly right hand helixde side left hand helix nde side direction of rotation from nde end clockwise shell door opening twofine coal grinding ball mill vs roller mill

COAL BASED THERMAL POWER PLANTS: COAL MILLS

Ball tube mills are either pressurized or suction type In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace In this type, leakage in the mill area is highIn the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cycloneIn this paper a multivariable decoupling control algorithm for the coalpulverizing system of a ball miller is provided It is based on a threeneuron control mechanism and solves the problem of long delay and strong coupling in ball mill coal pulverizing systems Our system has been used for more than a year, the principle and equipment of which have been proved effective and profitableA neural intellectual decoupling control strategy for a 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS Plant engineering solutions for any

crushing coal grinding mills used in power plants

Coal Mill Used In Power Plant coal mills used in power plants coal mills used in power plants excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (coal mills used in power plantsBall Mill Of Thermal Power Plant ball mill in thermal power plant ecopub The Ball Mill System (BMS) is a strongly coupled MIMO system,in order to implement a longterm automatic operation of the BMS effectively,and improve the automation level and efficiency, the stone present the overall design of the system,the control system is composed of Siemens SIMATIC S7400PLCS7200PLC,the PROFIBUS 「ball mill motor in thermal power plant」RPI also offers Ball Tube Mill Systems for large coal pulverizing applications firing abrasive Read More Coal mill pulverizer in thermal power plants SlideShare Nov 17, 2012 COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI Coal pulverizer/mill system One of the critical power plant components Read More Pulverizer Similar to the ring and ball mill, the verticalBall Mill For Coal Pulverizers In Belgium

Coal Mill Power Plant Classifier Pdf To The Crusher

Micronizer Coal Mill In Power Plant Crusher Mills, Micronizer mill alwar machine,Micronizer mill machine sale air classifier ball mill stone mobile crusher plant, coal grinding for power plants 4FT Standard Cone Crusher 22 Jul 2012 Pulverised coal power plants power plant, coal mill notes of coal mill in power three Riley Power doubleended ball tube mills Each mill can provide 65 tons per hour of pulverised coal to the boiler, or a total of 195 tons per hour, per boiler Because the balltube mills have outlets at each end, with a classifier on each outlet, two sample points were needed on each mill For enhanced reliability, a redundant configurationCOAL HANDLING SAFETY AMETEK LandCoal Mills in thermal power plant Mill Grinding Principles of grinding raw coal is fed into the mill for grinding grinding takes place by impact and attrition mill details design coal capacity tonshr ball charged tons speed to rpm screw assebly right hand helixde side left hand helix nde side direction of rotation from nde end clockwise shell door opening twofine coal grinding ball mill vs roller mill

about coal mill in power plant thaimassagebruggebe

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill where the grinding table and some heavy rollers pulverizes the coal The power plant’s net efficiency is simply the heat content of electricity (3600 kJ/kWh) divided by the heat rate (kJ/kWh) (see Equation 2) (2) The power plant’s heat rate depends on the fuel type used and the specific power plant design All the heat put into the plant that is not converted into electricity has to be dissipated somehow to theA simple model to help understand water use at power Properties of Coal • Coal properties are evaluated by different methods • The most commonly used methods are Proximate and Ultimate analysis of the coal • Proximate analysis gives the Moisture, Ash and Volatile matter, while the Fixed Carbon is found by difference • Ultimate Analysis gives the elemental composition of the coal • Other methods like Macarel analysis is also used Coal Properties and its influence on Boiler Pankaj Ekbote