Case

grinding process in cement manufacture

2022-09-25T22:09:33+00:00

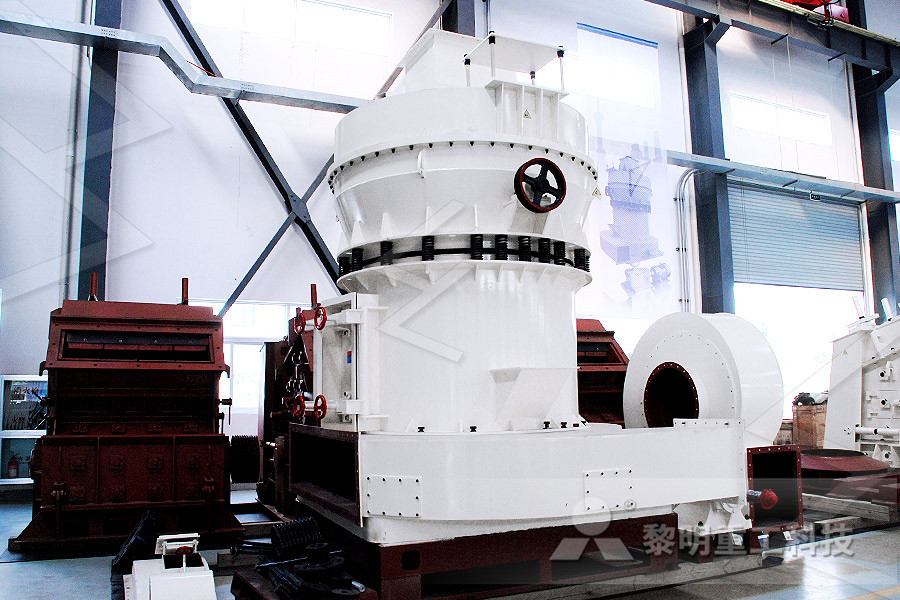

grinding process in cement manufacture QuinMedica

grinding process in cement manufacture Manufacturing of Portland Cement Process and Materials The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this grinding process in cement manufacture crushing grinding process in cement manufacturing XSD Sand Washer The efficient sand washing machine of XSD series is a kind of cleaning equipment of international advanced level for sand and slag pellets, developed on the basis of introducing foreign outstanding technology of the same kind of grinding process in cement manufactureOSTIGOV Technical Report: Improved control of the finish grinding process in cement manufacture Title: Improved control of the finish grinding process in cement manufacture Full RecordImproved control of the finish grinding process in

Improved control of the finish grinding process in

Activities developed on Task 6 of the Cement Clinker Project from July 1, 1985 to September 30, 1985 are described in this progress report Results on eight continuous ball mill tests are included Experimentation was performed in a 099 m diameter airswept mill at the Kennedy Van Saun facilities The process of manufacture of cement consists of The process of manufacture of cement consists of grinding the raw materials finely, mixing them thoroughly in certain proportions, and then heating them to about 1480 ° C in huge cylindrical steel rotary kilns 37–10 m in diameter and 50–150 m long and lined with special firebrick (The rotary kilns are inclined from the horizontal by about grinding process in cement manufacture/corpse grinderGrinding Process In Cement Manufacture Cement manufacturing process the cement manufacturing process starts with the mining of limestone that is excavated from open cast mines then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers as mentioned earlier coal isGrinding Process In Cement Manufacture hedde

Improved control of the finish grinding process in

Energy savings by improved control of the finish grinding process in cement manufacture: Final report, January 1, 1985December 31, 1986Grinding of manufacture of cement cement grinding cement packing and storage in the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80 of raw material Grinding Process In Cement ManufactureThe grinding process impacts the cement manufacture in at least two ways First, an increase of the fineness and homogeneity of the raw mix accelerates the clinkering reactions, leading to less variability of the clinker due to the enhanced stability of the kiln and better energy efficiency in producing a clinker of better consistencyCement Manufacture an overview ScienceDirect

The Cement Manufacturing Process CMA India

Cement Manufacturing Process The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles Limestone The manufacture of cement is a twophase process Clinker is first produced in a kiln system from calcareous (limestone, chalk or marl) and argillaceous (clay or shale) materials, with addition, in some cases, of small amounts of corrective materials (sand, waste bauxite, iron ore)Cement Manufacturing Process Flow Chartcost of grinding process in cement manufacture As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralscost of grinding process in cement manufacture

Cement Manufacture an overview ScienceDirect

The grinding process impacts the cement manufacture in at least two ways First, an increase of the fineness and homogeneity of the raw mix accelerates the clinkering reactions, leading to less variability of the clinker due to the enhanced stability of the kiln and better energy efficiency in producing a clinker of better consistencyWhat Is The Cement Manufacturing Process With Pictures May 12 2020 the cement manufacturing process involves several key steps including preparing the raw materials grinding the materials together heating the newly formed clinker in a kiln and finishing the cement with fine of the main ingredients used to make cement include limestone clay shale iron and ent manufacturing techniques will use Grinding Process In Cement Manufacturerotary Kiln MANUFACTURING PROCESS OF CEMENTWET PROCESS The wet process of cement manufacturing is divided into a number of stages a) Raw material extraction b) Grinding c) Proportioning and mixing and preparing composition based Manufacturing process of cement Wet Process

cost of grinding process in cement manufacture

clinker grinding process in cement taiwan Clinker grinding mill for Cement clinker grinding process Clinker Grinding Mill is the key equipment for grinding after the crush process and it is widely used in the manufacture industries such as cement silicate new Chat Online Back Grinding Process Pptcalimeroretiebe Get Price; The cement manufacturing processLafargeHolcim TanzaniaStep 2 – Material Grinding: At least 3 tons of materials (including various raw materials, fuel, clinker, etc) need to be ground to produce one ton of Portland cement According to statistics, the grinding process in the dry process of cement production line consumes more than 60% of the power of the whole plant, of which raw material Portland Cement Plant for Sale New Dry Process of The entire manufacture of portland cement process in a modern plant is now control through a microprocessor base programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is control centrally in a single control room and the plant employs minimum of manpower as compare to previous plants construct Manufacture of Portland Cement Process and

Use line diagram to show the dry process of cement

Use line diagram to show the dry process of cement manufacture Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Use line diagram to show the dry process of cement manufacture, quarry, aggregate, and different kinds of mineralsppt cement manufacturing process ppt on cement mill sainathramded CEMENT pptpdf Free download as 2016 acc cement animation ppt cement plant manufacturing process ppt cement acc cement Manufacture of Portland cement Methods of cement manufacturing 1 Wet process grinding and mixing of the raw materials in the existence of watercement mill process presentation droiddocket The manufacture of cement is a twophase process Clinker is first produced in a kiln system from calcareous (limestone, chalk or marl) and argillaceous (clay or shale) materials, with addition, in some cases, of small amounts of corrective materials (sand, waste bauxite, iron ore)Cement Manufacturing Process Flow Chart

cost of grinding process in cement manufacture

cost of grinding process in cement manufacture As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsLine diagram to show the dry process of cement manufacture Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Line diagram to show the dry process of cement manufactureLine diagram to show the dry process of cement This clinker is cooled and ground to fine power Usually it is gray or brownish in colour The manufacture of Portland cement consists of the following three distinct processes: 1 Mixing 2 Burning 3 Grinding Process # 1 Mixing: Mixing can be done either by dry process or wetprocessManufacture of Portland Cement: 3 Processes

Manufacture process of cement Step by Step

Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process Manufacturing Processes Of Portland Cement There are 2Types of Processes that can be used to Manufacture Portland Cement Which are : Wet Process Dry Process 11 DRY Process • The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 25cm size pieces separatelyManufacturing of cement SlideShareThe final process of cement making is called finish grinding Clinker dosed with Cost Of Cement grinding mill,cement vertical mill,cement raw mill Divided by cement production process, you will find four types of cement company including the cement plant, cement clinker factory, cement grinding plant and Cement Clinker Grinding Process cost of grinding process in cement manufacture

cost of grinding process in cement manufacture

clinker grinding process in cement taiwan Clinker grinding mill for Cement clinker grinding process Clinker Grinding Mill is the key equipment for grinding after the crush process and it is widely used in the manufacture industries such as cement silicate new Chat Online Back Grinding Process Pptcalimeroretiebe Get Price; The cement manufacturing processLafargeHolcim Tanzania Raw Materials in Cement Manufacture: (1) Limestone : Contains predominantly calcium carbonate (CaCO3) and to use in cement manufacture, it should have 4243% lime (CaO) minimum In cement manufacture it is prime raw material and its usage would be 90 93% (2) Clay : It contains more of silica (SiO2) and its usage should be 2 to 3% in cement Cement Manufacturing Process Civil Engineering Kiln and Kiln Shells: As a Cement kiln manufacturers we manufacture all type of process equipments including Vertical and roller Kiln and Shells Kiln Shells is involved in the process of burning the raw mixture thereby resulting in the clinker This clinker is then subjected to grinding to produce cementcement plant equipments manufacturer and suppliers