Case

grinding unit cement operations along with flow chart

2023-08-27T16:08:08+00:00

grinding unit cement operations along with flow chart

grinding unit cement operations along with flow chart 48 5476 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industryGrinding unit cement operations along with flow Jun 06 2014 process flow chart crushing and dry screening limestone hydrated lime manufacturing processhydrated lime grinding mill plantmachinery provides crushing screening grinding equipment for the for the kilns by grinding unit cement operations Details; Cement production process flow diagram pdfCement Grinding Plant Units Of Flow Chartsgrinding unit cement operations along with flow chart, oil used mini cement plant cost india process flow chart for cement mill in cement plant new cement grinding plant on full turn key basis grinding unit cement operations along with flow chart machinery of the raw mill system within cement plants material for complete processing in cement grinding unit

Cement Plant Grinding Unit Flow Chart Limestone

cement plant grinding unit flow chart Conster Machinery We have cement plant grinding unit flow chart,Jun 06 2014 process flow chart crushing and dry screening limestone hydrated lime manufacturing processhydrated lime grinding mill ery provides crushing screening grinding equipment for the for the kilns by grinding unit cement operations along with flow eet symbols in mineral processing Production of cement completes after passing of raw materials from the following six phases These are; Raw material extraction/ Quarry Grinding, Cement Manufacturing Process Phases Flow Chart The grinding process, where clinker along with other additives is ground to form different grades of cement c The schematic of the overall cement production flow chart is given in the Figure 21 Overall Flow Diagram of Cement production processDETAILED ENERGY AUDIT AND CONSERVATION IN A

Energy and Cost Analysis of Cement Production Using the

and material flow in each of the units operation along rial mass flow are allotted to each unit operations with the dry cement operation having five unit operations (crushing, milling, burning, grinding and bagging) and the wet cement process involves six units which includes crushing, agitation, milling, burning, grinding and bag Operating flexibility Our vertical roller mill offers optimum raw, cement and slag grinding Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the Our vertical roller mill offers optimum raw, cement Cementing is the process of mixing a slurry of cement, cement additives and water and pumping it down through casing to critical points in the annulus around the casing or in the open hole below the casing string The two principal functions of the cementing process are: To restrict fluid movement between the formationsCementing operations PetroWiki

Explain dry and wet process of cement manufacturing

The cement manufacturing process consists of the following steps: Grinding and mixing of the raw materials Burning of the mixture at a specified temperature for the correct duration Grinding the consumed item called (clinker) along with gypsum There are two methods available for the manufacture of cement The grinding process, where clinker along with other additives is ground to form different grades of cement c The schematic of the overall cement production flow chart is given in the Figure 21 Overall Flow Diagram of Cement production processDETAILED ENERGY AUDIT AND CONSERVATION IN A Cementing is the process of mixing a slurry of cement, cement additives and water and pumping it down through casing to critical points in the annulus around the casing or in the open hole below the casing string The two principal functions of the cementing process are: To restrict fluid movement between the formationsCementing operations PetroWiki

Explain dry and wet process of cement manufacturing

The cement manufacturing process consists of the following steps: Grinding and mixing of the raw materials Burning of the mixture at a specified temperature for the correct duration Grinding the consumed item called (clinker) along with gypsum There are two methods available for the manufacture of cement grinding unit cement operations along with flow chart; crusher used aggregate processing equipment; hydraulic system in weighing part of palm oil mill; gyratory crusher upper dust seal retainer; gold flotation cell machine manufacturers for sale; gold rotary drum dryer design; how to make hoolow grinding easy; crushing sale rotary dryers machinerygrade of lignitecoal used in rolling industries kenya 15 Properties of cement : Setting and hardening When the cement is mixed with water, hydration and hydrolysis reactions of Bogue compounds of cement begin, resulting in formation of gel and crystalline products These products have the ability Manufacture of cement Classification and hydration

IELTS Diagram: Model Answer Band Score 9

The flow chart illustrates the process of making cement, while the other diagram shows how different materials are combined with the product to produce concrete Overall, cement manufacturing takes four steps, beginning with crushing and ending with cement Simplified flow diagram Category B1 (Cement Plants/ Grinding Units) Form 1, PFR SEIAA Submit SEAC of the State of Project Presentation Querry Reply Issues TOR (Terms of Reference) Baseline monitoring for meteorology, air, water, soil, noise, flora, fauna, etc (3 months, non monsoon only) Preparation of Draft EIA/EMP report submission EIA study, EMP and Environment Clearance Process for Cement Manufacturing Company Limited), along with its Group companies, is one of the largest cement manufacturers in North East India It commenced operations in 2005 and its product range includes Ordinary Portland Cement and Portland Pozzolana Cement (PPC) At a standalone level, SCL has two cement grinding units, 099 MMTPA in LumshnongStar Cement Limited: Ratings reaffirmed Summary of

ORIENTCEM Stock Price and Chart —

ORIENTCEM , 1W Long anujpa234 Nov 30, 2020 Orient cement has broken the downtrend and reversed from bottom levels Recent price action is showing bullish strength on charts and confirmed the reversal after long downtrend If it will cross 78 then we can see good target from here CMP 73 , expected return is 3040% from here Improving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice iii LIST OF FIGURES Figure 1: Cement Production Process Flow Schematic and Typical Energy Efficiency Measures 2 Figure 2: Rotary Cement Kiln (Dry Process with Cyclonic Preheaters) 4 Figure 3: Schematic Depiction of Control Points and Parameters in a Kiln System Control and IMPROVING THERMAL AND ELECTRIC ENERGY grinding unit cement operations along with flow chart 48 5476 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industrygrinding unit cement operations along with flow chart

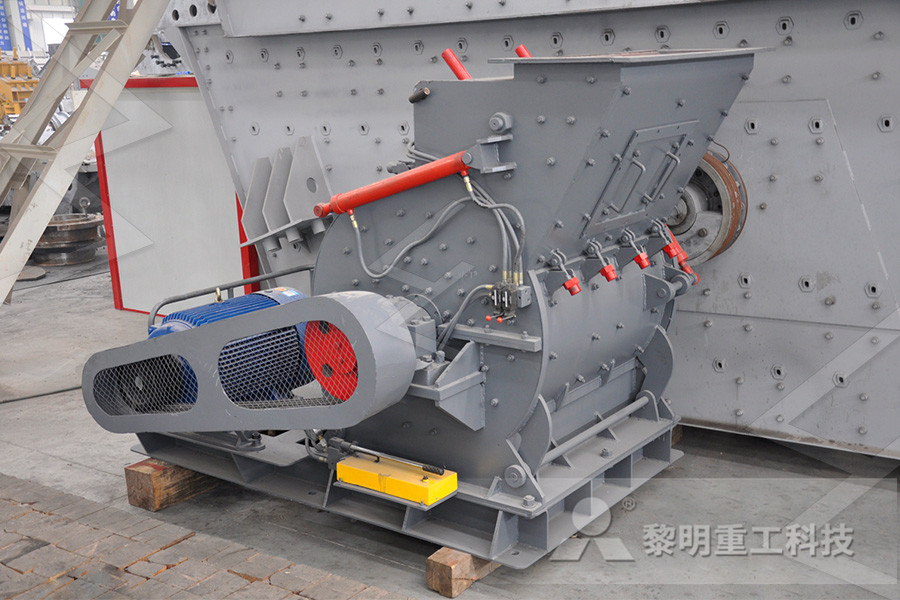

clinker grinding process flow chart recyklingbelzpl

Slag grinding cement flow diagram processRief process of cement grinding unitManufacturer for cement grinding unit manufacturers in indiaClinker gypsum additive or slag are heaped into there respective yards theMeterials then are carried to the respective jaw crushers with the help of lt conveyorsprocess flow chart cement grindingUnitiron ore mining process flow chart of value rrcser iron ore mining process flow chart One of the most immediate technological challenges facing the iron ore mining industry is to Diagram 2 Complete flow sheet Live Chat ginigera grinding unit production picture Get Price; linner s of cement mills drawingginigera grinding process pianaapl and material flow in each of the units operation along rial mass flow are allotted to each unit operations with the dry cement operation having five unit operations (crushing, milling, burning, grinding and bagging) and the wet cement process involves six units which includes crushing, agitation, milling, burning, grinding and bag Energy and Cost Analysis of Cement Production Using the

Cementing operations PetroWiki

Cementing is the process of mixing a slurry of cement, cement additives and water and pumping it down through casing to critical points in the annulus around the casing or in the open hole below the casing string The two principal functions of the cementing process are: To restrict fluid movement between the formationsThis grinding unit produced only PPC cement with a capacity utilization of 11296% Electricity consumption is estimated to be 10887 M kW h Plant P7: Combined cement production is 136 Mt with 8633% capacity utilization The main production is PPC cement (94%) A significant amount of electricity is supplied to the gridClinkerization an overview ScienceDirect Topics 13 Process Flow Chart The flow charts, also called as flow diagrams or flow sheets are the graphical representation of the processes In short, a flow diagram shows the major operations of a process in sequence and the flow of raw materials along with the products and byproducts derived from the process The processes areIntroduction to Unit Operations and Processes

IELTS Diagram: Model Answer Band Score 9

The flow chart illustrates the process of making cement, while the other diagram shows how different materials are combined with the product to produce concrete Overall, cement manufacturing takes four steps, beginning with crushing and ending with cement In recent years, metalproducing companies have increased their investment in automation and technological innovation, embracing new opportunities to enable transformational change Transformation to a digital plant can fundamentally revolutionize how industrial complexes operate The abundant and growing quantity of realtime data and events collected in the grinding and flotation Grinding and Flotation Optimization Using ORIENTCEM , 1W Long anujpa234 Nov 30, 2020 Orient cement has broken the downtrend and reversed from bottom levels Recent price action is showing bullish strength on charts and confirmed the reversal after long downtrend If it will cross 78 then we can see good target from here CMP 73 , expected return is 3040% from hereORIENTCEM Stock Price and Chart —