Case

why iron ore needs to be sintered

2023-01-05T20:01:53+00:00

Iron Ore Sinter an overview ScienceDirect Topics

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use Compared with pellets, production of sinter is cheaper, and compared with lump ore, fluxed sinter is often more reducible with better softening characteristicsFeb 22, 2021 Iron ore sintering is a type of powder metallurgy used to pretreat iron before using it in manufacturing applications Sintering involves heating iron powder to partially, but not completely, melt the iron particles The exact process used and additional elements involved vary, with some methods using gas or electricity in addition to heatWhat Is Iron Ore Sintering? (with pictures)The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process Sinter is the primary feed material for Sintering: A Step Between Mining Iron Ore and SteelmakingApr 02, 2010 As described in Chapter 14 on iron ore sintering, sintering involves the combustion of fossil fuels like coal and coke breeze to generate the heat required for sintering reactions Therefore, emissions from the sintering process arise primarily from the combustion reactions in the sintering bed on the traveling sinter strandOre Sintering an overview ScienceDirect TopicsNov 25, 2018 During the sintering process, the chemical reactions are taking place at high temperature and the iron ore and fluxes are combined together and form a sinter cake composed of iron ore, silicoferrites of calcium and aluminum (SFCA), dicalcium silicate and a glassy phaseTheory and Practice of Sintering of Iron ore – IspatGuru

Iron Ore to Sintering to Steelmaking Analyzing Metals

But before all that iron ore can be turned into steel, it must go through the sintering process Sinter is the primary feed material for making iron and steel in a blast furnace We recently wrote about sintering in our sister blog, Advancing MiningSintering is a process by which a mixture of iron ores, fl uxes and coke is agglomerated in a sinter plant to manufacture a sinter product of a suitable composition, quality and granulometry to be(PDF) Iron ore sintering Part 1 Theory and practice of Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux (limestone) fines In addition to base mix, coke fines, flux fines, sinter fines, iron dust (collected from plant dedusting system ESP) and plant waste are mixed in proportion (by weight) in a rotary drum, often called mixing and nodulizing drum Calcined lime is used as binder of the mixed material along with water (all in particular proportion by weight) to form feedsinter of about 5 to 7 mm in size This sinter globules are fSinter plant WikipediaWhat is Pelletization? The process of Pelletization helps converting Iron Ore Fines into “Uniform Size Iron Ore Pellets” that can be fed in the blast furnaces or in the DRI kiln (DRI) Why Pelletization? Pelletization is the only answer to a majorWhat is the difference between pellets and sinter? QuoraJul 10, 2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmakingIron Ore Pelletizing Process: An Overview IntechOpen

(PDF) Iron ore sintering Part 1 Theory and practice of

Nevertheless, despite this good knowledge of sintering, there are still a number of issues that need to be studied The present work provides information on the iron ores that form part of the Regions in which iron ore has formed over millions of years (eg through volcanism) and can be mined economically are also referred to as iron ore deposits Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia These countries account for around 85 % of the total global iron ore mining volumeIron ore mining and dressing tecscienceMay 18, 2017 Five iron ore agglomeration technologies can be defined: briquetting, nodulization, extrusion, pelletization and sintering Sintering and pelletization are the most important agglomeration technologies, in this way, in the EU27, 14 countries operate 34 iron ore sinter plants with 63 iron ore sinter strands, producing in the first decade of the twentyfirst century 130 million tons of sinter Iron Ore Agglomeration Technologies IntechOpenMar 15, 2015 fluxes, Iron ore fines, SCFA, sinter, sinter plant basic sinter, sintering machine, Understanding Sinter and Sinter Plant Operations Sintering is a process of agglomeration of fine mineral particles into a porous and lumpy mass by incipient fusion caused by heat produced by combustion of solid fuel within the mass itselfUnderstanding Sinter and Sinter Plant Operations – IspatGuruSep 12, 2018 Hence, the need to utilise lowgrade ore was paramount and this commenced the process of sintering and palletization Moreover, palletization is a process designed to transform iron ore fines into agglomerates to feed Blast Furnace (BF) and Direct Reduced Iron (DRI) producing unitsChanging dynamics of iron ore pellets industry Blogs

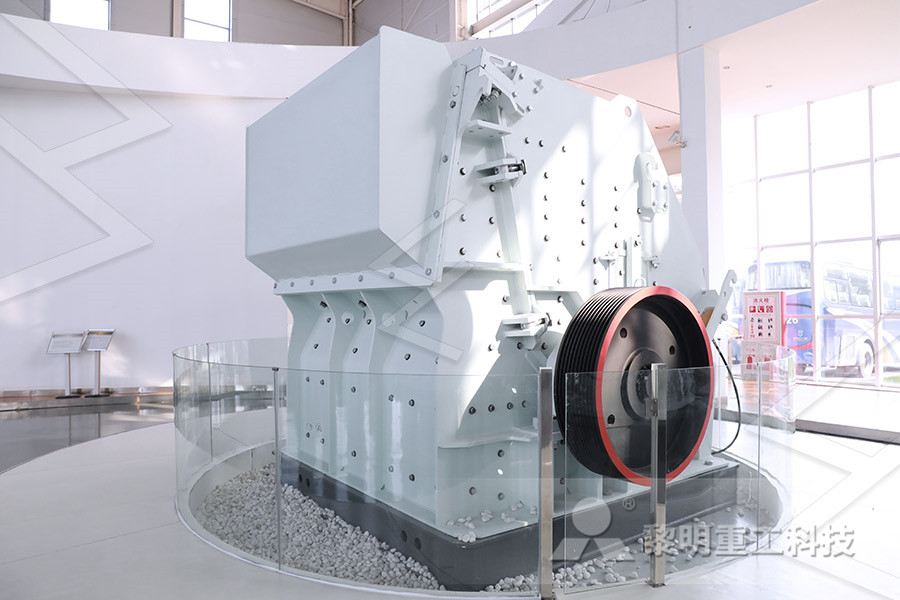

Design And Fabrication Of Iron Ore Sintering Machine

Jun 24, 2015 It may be recalled that grinding iron ore grinding step as needed by pelletising technique It may be recalled that grinding iron ore is very expensive process The iron ore particles from 10mm to 3mm are accepted directly for sintering The particles smaller than 05mm are nodulised to 3 – 4 mm size and then sintered iiiJul 10, 2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process Iron Ore Pelletizing Process: An Overview IntechOpenThe world will need iron ore for as long as the world needs steel In 2020, we produced around 280 million tonnes of iron ore That's enough to make the steel for more than 3,300 Sydney Harbour Bridges We're building a new iron ore mine in Western Australia When completed, South Flank will produce highquality iron ore for around 25 yearsIron ore BHPWhat is Pelletization? The process of Pelletization helps converting Iron Ore Fines into “Uniform Size Iron Ore Pellets” that can be fed in the blast furnaces or in the DRI kiln (DRI) Why Pelletization? Pelletization is the only answer to a majorWhat is the difference between pellets and sinter? QuoraFor example, the daily, weekly and monthly indices are listed because of the varied liquidity displayed by different parts of the market Sinter fines and lumps make up the bulk of the seaborne iron ore market, and are the products most frequently traded on a spot basis, so daily pricing is used for the key 62% Fe, 58% Fe and 65% Fe fines, and lump premium referencesIron ore pricing explained Metal Bulletin

Ore Assimilation and Secondary Phases by Sintering of Rich

During the iron ore sintering process, two types of particles are present in the sinter bed: (1) fines, which are actively taking part in melting and the formation of secondary phases, and (2) coarse ores, which are partially interacting with the surrounding melt The quality of the final sinter is particularly determined by the secondary phases and their bonding abilityIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaMay 05, 2007 Sintered iron ore by my understanding is heat treated to remove some of the noniron components which are driven off as gases and made brittle while the iron softens and to thus increase the concentration of iron per ton of ore So transporation costs are less with less weight of trash per pound of ironWhat's the usefulness of sintered iron ore to steel the iron ore standard sampling procedure given in the IMSBC Code should be followed Precautions for carriage of iron ore: Iron concentrates concentrates of iron are produced by either: the dry method, in which high grade ore is crushed to remove waste material, leaving a low moisture content in the powdered oreSafe carriage of Iron ore other iron concentrates in bulkKEY WORDS: iron ore sintering; flame front properties; temperature profiles; exhaust gas composition 1 Introduction Iron ore sintering involves the application of heat which causes the partial melting of a blended mix of ores, fluxes and coke breeze On cooling, the solidified melt provides the coherency need to form strong sinter particles TheEffect of Iron Ores and Sintering Conditions on Flame

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is May 05, 2007 Sintered iron ore by my understanding is heat treated to remove some of the noniron components which are driven off as gases and made brittle while the iron softens and to thus increase the concentration of iron per ton of ore So transporation costs are less with less weight of trash per pound of ironWhat's the usefulness of sintered iron ore to steel During the iron ore sintering process, two types of particles are present in the sinter bed: (1) fines, which are actively taking part in melting and the formation of secondary phases, and (2) coarse ores, which are partially interacting with the surrounding melt The quality of the final sinter is particularly determined by the secondary phases and their bonding abilityOre Assimilation and Secondary Phases by Sintering of Rich The world will need iron ore for as long as the world needs steel In 2020, we produced around 280 million tonnes of iron ore That's enough to make the steel for more than 3,300 Sydney Harbour Bridges We're building a new iron ore mine in Western Australia When completed, South Flank will produce highquality iron ore for around 25 yearsIron ore BHPWhat is Pelletization? The process of Pelletization helps converting Iron Ore Fines into “Uniform Size Iron Ore Pellets” that can be fed in the blast furnaces or in the DRI kiln (DRI) Why Pelletization? Pelletization is the only answer to a majorWhat is the difference between pellets and sinter? Quora

Types of Iron Ore: Hematite vs Magnetite INN

Fine iron ore must be agglomerated before being fed to a blast furnace either by pelletizing or sintering, which is normally done at the steel mill Fine iron ore cannot be fed to a blast furnace the iron ore standard sampling procedure given in the IMSBC Code should be followed Precautions for carriage of iron ore: Iron concentrates concentrates of iron are produced by either: the dry method, in which high grade ore is crushed to remove waste material, leaving a low moisture content in the powdered oreSafe carriage of Iron ore other iron concentrates in bulkMar 17, 2014 Not really – given there are a variety of iron products, a plethora of contaminants, such as Si, P, S, etc – even a variety of iron ore sizes, loosely termed lump and fines with need to be The seaborne iron ore cost curve MacroBusinessIron ore is a nonfungible commodity, and its quality varies To help facilitate price adjustment for differences between expected and delivered product specifications, PRAs have developed valueinuse (VIU) indices for the key priceaffecting chemical components of iron ore ironIron ore pricing explained Metal BulletinDuring the extraction of hematite(ore mining), very small sized iron particles are obtained If particles of such sizes are directly used in the blast furnace for obtaining iron, they would choke the tuyeres and may even cause explosion inside thWhy is sinter used in a blast furnace? Quora

The Important Factors to Consider When Investing in Iron Ore

With iron ore firms, the major metric that an investor needs to look at is cost per ton Cost per ton will typically include the costs of mining, processing, and any SGA that is associated with This explains why sintering investigations using Australian ores containing kaolinite and aluminous goethite produce higher quality sinter compared with ores containing alumina in the form of gibbsite Figure 1 shows sample results from an in situ Xray diffraction experiment using an Algoethite rich iron ore Compared to iron ores containing Understanding iron ore analytical tools – Process Concentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metal Reduction is the final, hightemperature step in Lead smelting Wikipedia