Case

molybdenum ore processing

2020-07-07T20:07:56+00:00

Molybdenum Processing IMOA

Molybdenum processing Milling Ball or rod mills crush and grind the mined ore to fine particles that may be only microns (103 mm) in diameter, releasing molybdenite from the gangue (worthless rock) The Molybdenum Process Flowsheet In the crushing department, which is designed for 8hour per day operation, a heavy duty apron feeder, with plenty of length for picking purposes, starts the ore on its way The crusher operator with his assistant can sort out any high grade ore, Molybdenum Ore Processing by Flotation 911 Molybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficientMolybdenum processing Britannica

Molybdenum ore processing Dewo Machinery

In the beneficiation process, the beneficiation method of molybdenum in China is mainly flotationIn the deep selection of molybdenumbased ores containing trace amounts of copper, a partial mixing priority flotation process was employedAt present, China also recovers molybdenum from copper molybdenum oreThe mining of molybdenum ore includes open cast pit technology and the underground block caving technique Molybdenum processing includes several processes, such Molybdenum: mining and processingMetalpedia Lowgrade oxide ore leaching with sulfuric acid to extract pure molybdenum trioxide exchange or extraction from solution using ion In addition, molybdenum smelting methods, as well as lime calcination, leaching nitrate, sodium hypochlorite leaching, electrooxidation leaching methodMolybdenum ore processing technology

Mineral Processing 101 : Molybdenum Ore

Overview of Molybdenum Ore Beneficiation The beneficiation processing of molybdenum ore is mainly performed by flotation, and the recovered molybdenum mineral is molybdenite(MoS 2) Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the concentrated molybdenite would be subjected to a further step of chemical beneficiation processingMolybdenum mining processing Molybdenum mining and processing techniques have been improved continuously since the first mine was started at Climax near Leadville, Colorado in 1916 Today, the principal moly mines, both primary and byproduct, are Molybdenum Mining and Processing IMOA If the ore is located deep underground, underground block caving technology is adopted Large pieces of ore are cut from the bottom and collapse under their own weight, and the resulting ore is transferred to the ground for the processing Molybdenum Processing 1 GrindingHow Is Molybdenum Mined and Processed?

Molybdenum Beneficiation Basis

The crushing of molybdenum ore generally uses a threestage oneclosedcircuit process, and the final product size is 1215 mm Usually use the ball mill or rod millball in the ore milling process But there are also some processing flows adapted Molybdenum: mining and processing; Mining; Molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products Molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly copperMolybdenum mines are classified into three groups Molybdenum: mining and processingMetalpediaMolybdenum ore processing process and beneficiation equipment Molybdenum is a highquality metal with high melting point, corrosion resistance and wear resistance It is widely used in metallurgy, machinery, aerospace, national defense, building materials, electrical and other fieldsMolybdenum ore processing process and

Molybdenum Mining and Processing IMOA

Molybdenum mining processing Molybdenum mining and processing techniques have been improved continuously since the first mine was started at Climax near Leadville, Colorado in 1916 Today, the principal moly mines, both primary and byproduct, are 200TPD molybdenum Ore Processing Line ,molybdenum ore processing plant Henan Xingyang Mining Machinery Manufactory US $$ / Set 10 Sets (Min Order) Contact Supplier Transaction Level Add to Compare China Molybdenum Ore, China Molybdenum Ore 98% of the industrial mineral containing molybdenum is molybdenite Flotation method is often used to extract molybdenum concentrate In processing Molybdenum ore, to focus on preventing over grinding, and in the production process, multistage grinding and multistage separation process are generally adopted, to gradually achieve Molybdenum monomer liberation, and to ensure the high grade of China Molybdenum Ore Processing Plant EPC

Molybdenum beneficiation and smelting technology

For example, the ore processed by a molybdenum concentrator has a high grade of ore (02% to 03%), and the enrichment ratio is 133 to 155 The original design of the total number of beneficiation is 7 times, and the ore processed by another concentrator The molybdenum grade of the raw ore is about 01%, the enrichment ratio is 430520, and the processing1 In 1993, one mine extracted molybdenum ore, and nine mines recovered molybdenum as a byproduct Two plants converted molybdenite concentrate to molybdic oxide, which was used to produced ferromolybdenum, metal powder, and other molybdenum compounds2 Exhibit 1 presents the names and locations of molybdenum mines and processing MOLYBDENUM, FERROMOLYBDENUM, AND tion of the approach at a copper–molybdenum ore processing plant is instantiated The developed flow chart allows production of quality copper, molybdenum and pyrite concentrates The authors also describe the approach to estimating processibility of tailings of process stages It is shown that it is feasible toPOTENTIAL ENHANCEMENT OF COMPREHENSIVE

Molybdenum Climax Molybdenum A Freeport

Climax Molybdenum Company, a subsidiary of FreeportMcMoRan, has two primary mines in Colorado, with the Henderson mine currently operating half a mile under the Continental Divide More than 2,000 pounds of ore must be mined underground, crushed and milled to recover some four to six pounds of molybdenum Encompassing approximately 994 km 2 (2,457 acres) as well as several nearby villages, the facility includes an open pit mine, a rock crusher, a 1,900meterlong covered ore conveyor belt, a nonferrous metal production plant, dressing and processing plants, a molybdenum North Korea's Expansion of Molybdenum Production Molybdenum metal is a very important metal, which is known as war metal With high strength, high melting point, corrosion resistance, wearresisting, so it is widely used in industry Technical Process The processing technology of molybdenum ore mainly includes three processes: crushing, grinding and ore dressingMolybdenum ore processing technologyBAILING®

Molybdenum ore processing process and

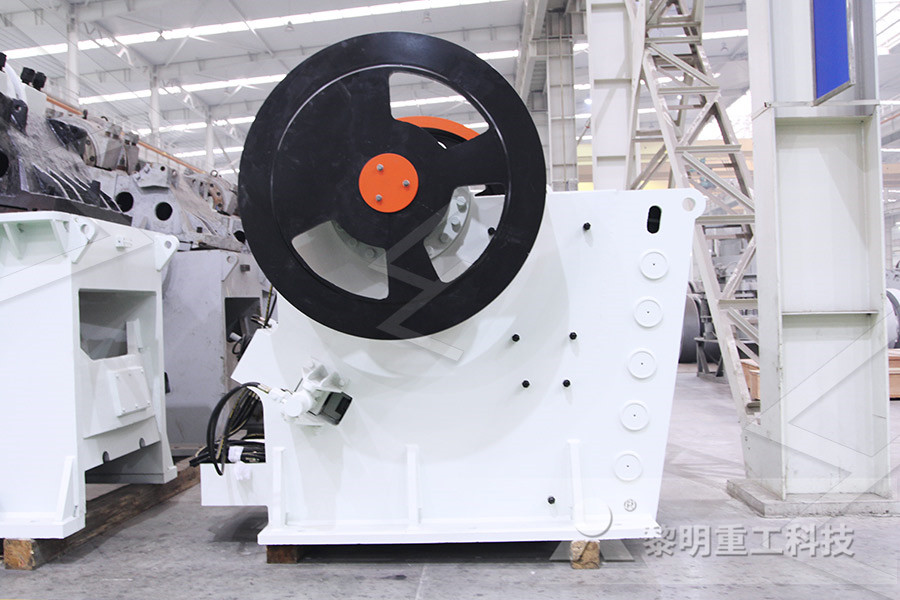

Molybdenum ore processing process and beneficiation equipment Molybdenum is a highquality metal with high melting point, corrosion resistance and wear resistance It is widely used in metallurgy, machinery, aerospace, national defense, building materials, electrical and other fieldsMolybdenum ore processing by flotation this molybdenum flotation circuit based on tons per 24 hours is designed for lowgrade molybdenum ore having highgrade streaks and with pyritequartz is also basically sound for many other friable sulphide ores such as antimony silver and even some lead ores Molybdenum Ore ProcessingJaw CrusherMolybdenum Ore Processing by Flotation This molybdenum flotation circuit, based on 250500 tons per 24 hours is designed for lowgrade molybde Molybdenum Mining Molybdenum is contained in various minerals, but only molybdenite (MoS 2) is suitable for the industrial production of marketable molybdenum pof molybdenum ore processing maciejchorowskipl

200TPD molybdenum Ore Processing Line

200TPD molybdenum Ore Processing Line ,molybdenum ore processing plant, You can get more details about from mobile site on malibaba $215,00000 $220,00000 Min Order : 1 Set The filtrate was analysed with ICP for molybdenum, potassium and sulphur The significant amount of sulphate (about 15 g/l sulphur) caused problems in the further processing route of the low grade molybdenum ore and therefore should be lowered 23 Sulphate removal from the dissolver liquidComprehensive processing of low grade sulphidic For example, the ore processed by a molybdenum concentrator has a high grade of ore (02% to 03%), and the enrichment ratio is 133 to 155 The original design of the total number of beneficiation is 7 times, and the ore processed by another concentrator The molybdenum grade of the raw ore is about 01%, the enrichment ratio is 430520, and the Molybdenum beneficiation and smelting technology

Molybdenum Dressing Production Line Yantai

Molybdenum ore processing and equipment Molybdenum ore rough crushed by Jaw crusher , then grinded into a suitable particles transport by conveyor to storage 1Feeded by feeder into ball mill for grinding 2The product after ball mill is Molybdenum ore grade of 40% to 80%, nickel products at 25% to 40%, sulfur 23% Invention of the total recovery of nickel, molybdenum were 90%, 94%, simple equipment, easy operation, no waste, good economic returnsNickelmolybdenum mine production technologyAccording to the properties of a complex coppermolybdenum ore,experimental study on mineral processing has been conductedThe copper and molybdenum minerals are successfully separated from the gangue minerals with sodium sulfide and ammonium sulfate Flotation of a CopperMolybdenum Ore《Nonferrous