Case

ball grinding ating

2021-12-02T08:12:42+00:00

Carbide Coated Ball Grinding YouTube

Jul 24, 2015 Here we have a small clip of a Valve Ball that was first Coated with Tungsten Carbide, and is now in the process of being Ground and Rinsed down to size OncOur coating is applied to the metal substrate using a 6Axis Robot The valve ball is then ground and polished to a superfinish on specifically designed Valve ball grinding equipment to meet tight tolerance requirements on the finished ballValve Balls Thermal Spraying Process AA CoatingsCarbide Technologies is proud to announce our Ball Grinding services After a Ball Valve has been Carbide Coated, we can Grind the ball to your specific dimensions and are capable of reaching a polished Finish of 35 RMS Feel free to contact us with any inquiries Carbide Coated Ball GrindingGrinding Carbide Technologies IncCarbide Technologies IncNov 17, 2011 HVOF Ball Coating by Watson GrindingHVOF Ball Coating by Watson Grinding YouTubeAdditionally, we are industry leaders in spherical grinding and are capable of precisely grinding ball valve balls up to 53″, particularly for use in severe service applications Our thermal spray coatings offer corrosion and wear resistant solutions for critical componentsServices Thermal Spray Coatings Texas Watson Grinding

ball valve ball grinding solution DANOBAT

ball valve ball grinding solution ball valve ball grinding solution 75% reduction of cycle time in your ball valve ball grinding solution Internal grinding Benefits HVOF and Spray Fuse coating; IRD: internal, external radius grinding Workpiece length up to 400 mm; Workpiece ID up to 200 mm; Max spindle number: up to 4;Sep 15, 2018 But with the right coating, a smoother sliding operation can take place between the seat and ball, reducing friction Wear and damage due to thermal swings, cavitation, particle impact, erosion, abrasion, and galling will be reduced The valve’s operating torque Understanding MetalSeated Ball Valve Coating Materials Grinding Media Grinding Balls Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needsGrinding Media Union ProcessMar 18, 2021 There are three reasons for coating a ball valve, according to Brian Hood, product manager, US Flowserve The first reason is that “you’re using it on metaltometal seating to prevent galling,” he explains The second is the need for wear resistance, and Ball Valve Coatings: Different Coats for Different AppsDec 11, 2015 The OEM required precision grinding and finishing services for their hardclad plated balls, which are used in highperformance ball valves At Duval, precision is our only product We understand that your components need to integrate perfectly into larger assemblies or systemsPrecision Spherical Grinding for HighPerformance

Grinding Carbide Technologies IncCarbide Technologies Inc

NEW Carbide Technologies is proud to announce our Ball Grinding services After a Ball Valve has been Carbide Coated, we can Grind the ball to your specific dimensions and are capable of reaching a polished Finish of 35 RMSGrinding Media Grinding Balls Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needsGrinding Media Union Processball valve ball grinding solution ball valve ball grinding solution 75% reduction of cycle time in your ball valve ball grinding solution Internal grinding Benefits HVOF and Spray Fuse coating; IRD: internal, external radius grinding Workpiece length up to 400 mm; Workpiece ID up to 200 mm; Max spindle number: up to 4;ball valve ball grinding solution DANOBATThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsDec 11, 2015 Recently, Duval Precision Grinding was approached by a manufacturer of highperformance valves that are used in some demanding applications The OEM required precision grinding and finishing services for their hardclad plated balls, which are used in highperformance ball valvesPrecision Spherical Grinding for HighPerformance

Research on the high temperature oxidation mechanism of

Jan 01, 2021 The commercial Cr 3 C 2 –NiCr and CoCrMo powders were mixed by the ball grinding method and then dried in a vacuum oven, as shown in Fig 1The characteristics of the Cr 3 C 2 –NiCr powder from Golden Egret Geotools company (XTC) and the CoCrMo powder from Avimetal Powder Metallurgy technology company (AMC) are shown in Table 1Subsequently, the dried powders were Mar 15, 2021 Coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their durability and effectiveness But because they are faced with such a diversity of challenges, there are a broad number of differences in the types of coatings used The coatings used for ball valves have their own set of characteristics that differ in many cases from other types of Ball Valve Coatings: Different Coats for Different AppsAs one of the nation's fastestgrowing industrial manufacturing facilities, BW Grinding Service INC excels at providing fullservice manufacturing, coating, and grinding Our facility covers almost two acres of floor space and uses stateoftheart machinery and coating techniques to bring you the quality products you expectIndustrial Manufacturing BW Grinding Service INCFW Gartner’s facilities also have onsite grinding capabilities and an extensive metallographic laboratory By utilizing a worldwide network of partnerships and affiliations with other thermal spray coating and laser cladding providers, we are able to support OEMs on a global scaleFW Gartner Thermal Spraying CurtissWright Surface The attrition ball mill type CAO 2000 is especially designed for the intermediate or fine grinding of cocoa liquor, chocolate and compound coatings more info CAO 3000[2]CHOC INLINEBallmill: Caotech BV manufacturer of ballmill equipment

Effects of Heat Treatment Process on Microstructure and

3HEAT TREATMENT STUDY 31 Pretest Treatment The ascast grinding balls with the diameter of 110 mm were selected randomly from the grinding balls produced by the sandcoating process in the iron mould, and 16 standard impact samples with the dimension of 55mm * l0 mm * l0 mm were cut by linear cutting machineNo shrinkage or porosity was found in the sample taken from the middle of the Zirconia Ball Mill Grinding, Ball Grinding Mill Machine, Grinding Ball Mill Machine manufacturer / supplier in China, offering Lab Ball Milling Machine/Planetary Ball Mill for Large Range of Materials Media, HighPrecision RolltoRoll Doctor Blade Coating Machine Is Suitable for Laboratory Battery Electrode Coating, Suitable for The Study of Ferromagnetic Materials Magnetic Suspension Vacuum China Lab Ball Milling Machine/Planetary Ball Mill for Sand Ball Mill is the key equipment for crushing the material after it is broken Ball mill is widely used in cement, Portland products, new building material, refractory material, fertilizer, black and Ball Mill Sand Ball Mill Manufacturer from MumbaiIn addition to thermal spray, HTS Coatings is a fullservice precision machine shop We offer both machining and grinding and can perform precision lathe machining, including inner diameter (ID) operations Machining and grinding services can also be used during the thermal spray repair and overhaul processMachining Grinding Cylindrical Grinding HTS Coatings1Application Zirconia silicate grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin Zirconium silicate Grinding BallZirconium silicate

Grinding Media Union Process

Grinding Media Grinding Balls Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needsAt AA Coatings, we have just the coating materials needed to deal with your metal seated ball valves For that matter, we have thermal spray protective coatings for every industry imaginable It’s time to deal with a protective coating company that has your specific needs and requirements in mindUnderstanding MetalSeated Ball Valve Coating Materials In addition to thermal spray, HTS Coatings is a fullservice precision machine shop We offer both machining and grinding and can perform precision lathe machining, including inner diameter (ID) operations Machining and grinding services can also be used during the thermal spray repair and overhaul processMachining Grinding Cylindrical Grinding HTS CoatingsA knife or dental style scraper is normally used when a scraping method is desired A hand held drill is normally used when a grinding technique is desired A wide variety of rotary abrasive materials including ball mills may be required To determine the appropriate coating removal procedure the coating must first be identified235 Coating Removal, Grinding/Scraping MethodJul 09, 2019 Skeptical about the benefits of highperformance tool coatings? So was one of Kyocera’s customers in the power generation industry The company had recently transitioned from grinding to milling of a copper 110 alloy workpiece, and quickly discovered that edge buildup was creating unacceptable tool life and poor part quality in the gummy material7 MustKnow Tool Coatings for HighPerformance Machining

Ball Valve Coatings: Different Coats for Different Apps

Mar 18, 2021 Coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their durability and effectiveness But because they are faced with such a diversity of challenges, there are a broad number of differences in the types of coatings used The coatings used for ball valves have their own set of characteristics that differ in many cases from other types of DK Machine offers valve ball and seat manufacturing and repair, and provides spherical grinding services for many industries including military, mining, pulp and paper, petroleum and chemical We produce precision valve balls for use in severe duty, high pressure, and high tolerance applicationsDK Machine Valve Balls, Seats, Spherical Grinding, and About us Hofmann is a The global wellknown top quality wear resistant ceramic manufacturer and specializes in the supply of cost effective solutions to wear problems by offering nonmetallic high tech material Over 20 years experience for wear protection ceramic lined equipment, research and production with An ISO 9001 Certified companyGrinding Media And Ball Mill Liner Hofmann Engineering grinding with an inert medium – the use of nonferrous grinding media in IsaMills avoids the formation of iron hydroxide coatings on the surfaces of fine particles that occurs when using steel balls as the grinding medium The presence of the iron hydroxide coating inhibits flotation of these particlesIsaMill WikipediaSilicon Nitride Grinding Ball Bearing Si3n4 , Find Complete Details about Silicon Nitride Grinding Ball Bearing Si3n4,Ceramic Ball,Silicon Nitride Balls,Si3n4 Ball from Bearing Balls Supplier or ManufacturerTaian Xinxin ImportExport Co, LtdSilicon Nitride Grinding Ball Bearing Si3n4 Buy Ceramic

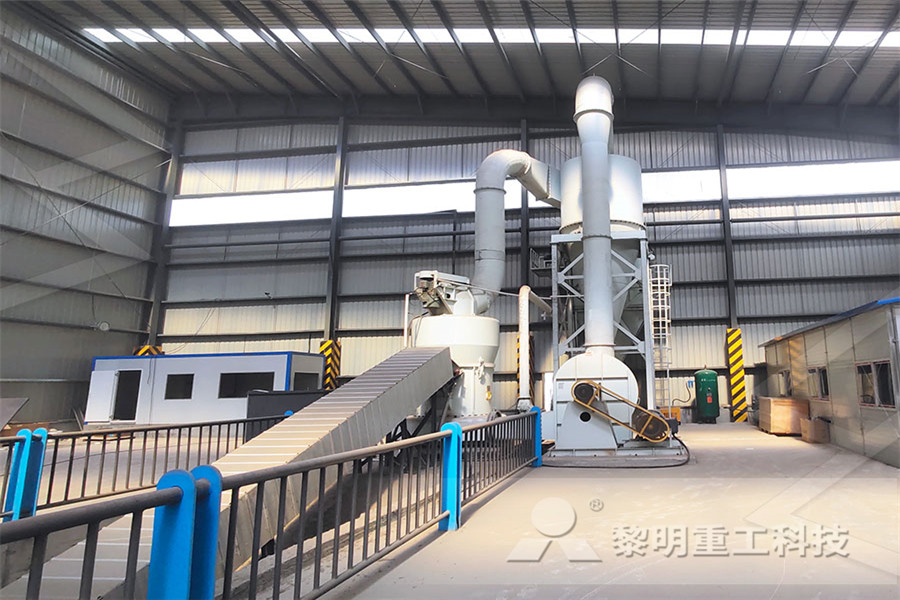

Grinding solution for Hastalloy HVOF coating

Hi friends, Anybody has related experiences that grind Hastalloy HVOF coating could be share, we met a problem that polished or grinding process can not got good results which made coating smooth and low roughness to Ra01, thanks a lot!At , we sent 1 set of ball mill grinding plant and coating plant to Egypt, to grind the calcium carbonate to 8 micron, 10 micron and 15 micron, and coat it The assembly of ball mill plant is 22*55M Ball mill plant+ AMS8003 classifier+XMC605 bag dust catcher and the coating system is UCOAT750 coating plant with classifierBall mill grinding plant with classifier and coating Sand Ball Mill is the key equipment for crushing the material after it is broken Ball mill is widely used in cement, Portland products, new building material, refractory material, fertilizer, black and Ball Mill Sand Ball Mill Manufacturer from Mumbai